On the shop floor, we don’t have time for overcomplicated systems. What we need is equipment that runs reliably, cleans parts fast, and doesn’t eat up maintenance hours. That’s exactly what a tumble belt shot blasting machine does.

In most manufacturing workshops, surface preparation is one of the key steps before painting, coating, or further machining. A tumble shot blasting machine has become a workhorse in this process because of its efficiency and reliability.

How It Works in Practice

You load a batch of parts onto the belt, hit the start button, and the belt begins tumbling the parts while steel shot blasts across them at high speed. Because the parts keep moving, every surface gets hit. No dead spots, no uneven cleaning. Once the cycle ends, you unload, and the next batch goes in. Simple and efficient.

Why It Helps Productivity

- Batch Loads: Instead of cleaning one piece at a time, you can process dozens—or even hundreds—depending on the size.

- Consistent Cycle Times: Every batch runs the same, which helps keep production schedules on track.

- Low Maintenance Downtime: The machines are built tough, and with regular checks on the belt and blast wheels, they stay online without unexpected stoppages.

Quality You Can Count On

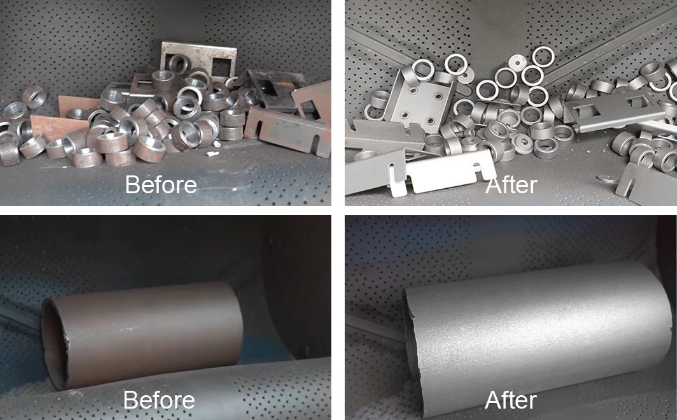

Rust, scale, old paint—gone. The machine leaves a clean, roughened surface that’s ready for coating, painting, or machining. Parts come out uniform, which means fewer rejects and reworks. And for critical components, the blasting can even improve fatigue strength, giving parts longer service life.

Typical Jobs

We run castings, forgings, and fasteners through these machines every day. They handle all sorts of shapes—bolts, gears, brackets—without us needing to adjust much between loads. It’s a workhorse for any foundry or machining workshop.

Tumble shot blasting machine is one of the most practical tools in the workshop. It saves time, improves product quality, and cuts down on manual work. If you’re running bulk parts through your process, this machine is hard to beat.

How Tumble Shot Blasting Machine Actually Helps Us Improve Both Productivity And Product Quality

1. Continuous and Uniform Cleaning

The biggest advantage is the way parts are handled. The tumbling action keeps components constantly moving under the blasting stream. This ensures every side of the part is exposed to the abrasive, removing rust, scale, and sand residues evenly. For castings and forgings, this means a much cleaner surface without extra manual work.

2. Time Savings on Large Batches

For workshops that process hundreds of small- to medium-sized parts daily, manual cleaning or single-piece blasting wastes a lot of time. A tumble machine allows us to load a full batch, press start, and let it run automatically. In many cases, one cycle can clean an entire load within 15–20 minutes. This reduces downtime and keeps production flow steady.

3. Improved Coating Adhesion

We all know that paint, powder, or plating will only stick well on a clean, roughened surface. The machine not only removes contaminants but also creates the right surface profile for better adhesion. That translates to fewer coating defects, longer service life of products, and less rework.

4. Lower Labor Intensity

Before using shot blasting, operators had to grind or brush parts manually, which was slow and exhausting. Now, most of the hard work is handled by the machine. Workers only need to load and unload the drum, which improves safety and reduces fatigue.

5. Consistency in Quality

Manual cleaning depends on operator skill, and results can vary. With the tumble shot blasting machine, every batch receives the same blasting intensity and coverage. That consistency is crucial for industries like automotive, foundry, and general metalworking, where uniform surface quality is a must.

6. Cost Efficiency in the Long Run

Although the machine is an investment, the savings from reduced labor, faster cycle times, and less rework quickly add up. In my workshop, we noticed that after six months of running, the tumble shot blasting machine had already paid for itself in cost savings.

Conclusion

Tumble shot blasting machine isn’t just a piece of auxiliary equipment—it directly influences the quality of the finished product and the overall throughput of the workshop. For any manufacturer dealing with castings, forgings, or metal parts that need surface preparation, it’s one of the most practical solutions to boost both productivity and quality.