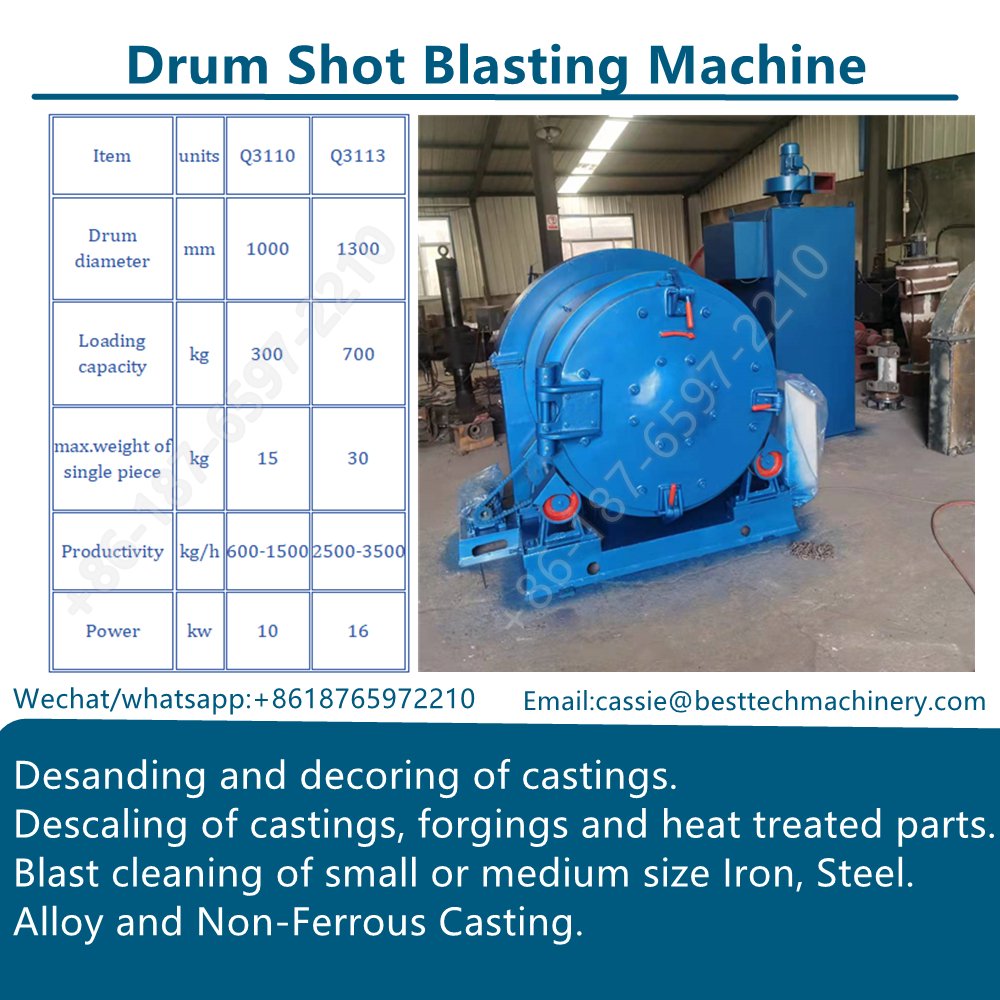

Rolling Drum Shot Blasting Machine is a type of surface cleaning equipment specially designed for small and medium-sized workpieces that can tumble freely during the blasting process. The machine uses a rotating drum to continuously turn the parts while high-speed steel shots from the blast turbines impact the surface to remove rust, sand, scale, burrs, and surface contaminants.

Practical Considerations You Should Note Before Making The Decision

When selecting a Rolling Drum Shot Blasting Machine, many customers only focus on price or blasting capacity. However, for a foundry or metal processing plant, the right machine must match the workpiece characteristics, production rhythm, and equipment reliability.

1. Workpiece Type and Drum Structure Compatibility

The rolling drum shot blasting machine is mainly suitable for:

- Small to medium-sized castings

- Forgings

- Heat-treated parts

- Parts not afraid of collision

Before choosing, the user must confirm:

- Drum size: Larger diameter = smoother tumbling; smaller diameter = higher productivity for small parts.

- Drum shape: Hexagonal drum design gives better tumbling but needs careful workpiece compatibility check.

- Workpiece maximum dimension & weight: Ensure enough space for turning without jamming.

2. Blasting Efficiency and Turbine Shot Blaster Configuration

Blasting performance mainly depends on:

- Number of blast wheels

- Power of each turbine

- Shot flow rate

- Blast pattern coverage

Engineer point of view:

A good design must ensure uniform shot distribution inside the drum. Even if the machine uses high horsepower turbines, wrong shot direction or poor drum geometry will still cause uneven cleaning results.

3. Wear Resistance and Drum Material Selection

The drum is the most critical wear component.

Common options:

- Mn13 high manganese steel

- Cast alloy liner plates

- Rubber-lined drum (for less aggressive applications)

For long-term stability, the machine should use wear-resistant materials at:

- Drum inner wall

- Separation unit

- Shot circulation system

- Wear guard plates near the blast wheel

Good wear design reduces downtime and maintenance cost.

4. Shot Circulation and Separation Quality

Stable blasting requires clean and continuous abrasive circulation.

Key technical points:

- Air separator efficiency (removes dust, sand, and broken shots)

- Elevator lifting capacity

- Screw conveyor speed matching

- Abrasive storage hopper stability

If separation is poor, dust and contaminants will damage the turbine blades quickly.

5. Dust Collector Performance

The blasting process creates large amounts of dust. A high-efficiency dust collector is essential.

Recommend to choose:

- Cartridge dust collector with large filtration area

- Pulse jet cleaning for stable suction

- Easily replaceable filter elements

Good dust control ensures clean workshop environment and longer machine service life.

6. Loading/Unloading Method and Automation Level

Choose based on production requirements:

- Manual loading (small batches)

- Hydraulic lift loading

- Automatic feeding conveyor

- Integrated production line connection

Higher automation reduces labor intensity and improves consistency.

7. Safety and Maintenance Convenience

Important but often overlooked:

- Maintenance access doors

- Safety interlock switches

- Wear parts replacement time

- Monitoring windows

- Emergency stop design

A machine with proper maintenance space saves many hours every month.

8. Manufacturer Experience and After-Sales Support

Rolling drum shot blasting machine seems simple, but engineering design varies greatly.

Before purchase, confirm:

- Years of experience in drum-type blasting machine

- Availability of spare parts

- Engineering drawings and structural design strength

- On-site commissioning and training service

A reliable supplier ensures stable production after installation.

Conclusion

Selecting a Rolling Drum Shot Blasting Machine is not only about capacity or price. You must consider workpiece characteristics, blasting efficiency, wear protection quality, dust-removal system, automation level, and after-sales support. A well-chosen machine will provide stable and efficient surface cleaning with long service life.