Over the past few years, I’ve visited many foundries upgrading their core-making workshops. Almost every plant manager asks me one question:

“Is a hot box core shooting machine really worth the investment?”

Many people only look at the machine price tag. But in real production, what matters is Total Cost of Ownership (TCO) — including energy use, resin cost, tooling life, labor, maintenance, and environmental compliance.

Based on real foundry operating conditions, let me walk you through a practical cost analysis — the same logic I use when helping clients choose core-making equipment.

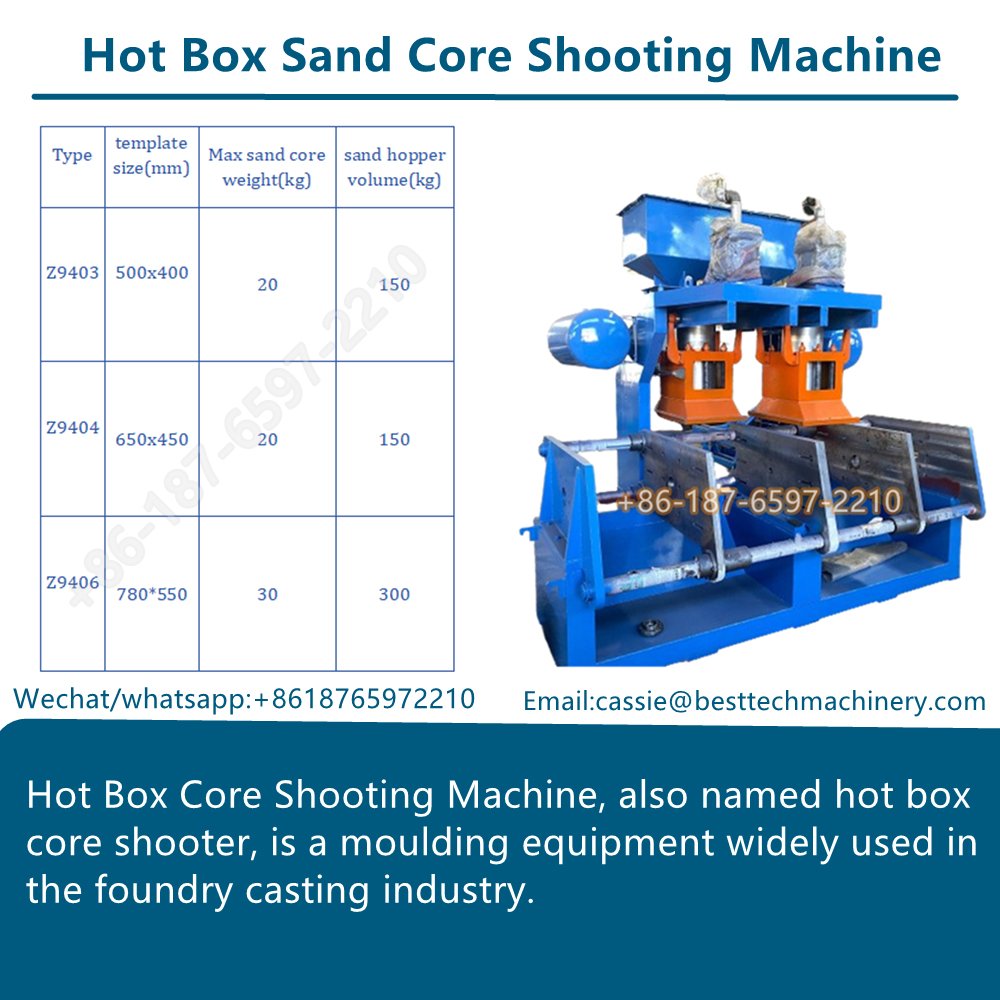

What Is a Hot Box Core Shooting Machine?

Hot box core shooting machine produces sand cores by shooting resin-coated sand into a heated metal core box. The resin cures instantly under high temperature, forming strong and dimensionally accurate cores.

Typical operating parameters in industrial production:

- Core box heating temperature: 200–280°C

- Curing time: 10–30 seconds per core

- Core bending strength: ≥ 2.0 MPa

- Output capacity: 60–180 cores/hour

Compared with cold box or CO₂ processes, hot box technology offers faster cycle time, higher core strength, and excellent dimensional stability — especially suitable for high-volume core production.

Why Cost Analysis Matters

In today’s casting market, profit margins are tight. Saving just a few seconds per core or reducing scrap by 1–2% can translate into thousands of dollars per month.

A correct cost evaluation must include:

- Equipment investment

- Tooling life

- Energy consumption

- Resin usage

- Labor cost

- Maintenance

- Environmental compliance

Only by looking at the full picture can you make the right investment decision.

1. Initial Equipment Investment Cost

Hot box core shooting machines are available in different automation levels.

Typical investment range:

- Small manual model: USD 7,000 – 9,000

- Medium automatic model: USD 9,000 – 120,000

- Fully automated core line: USD 150,000 – 300,000+

My engineering suggestion:

Always match machine capacity to real production demand. Oversized machines increase power consumption and idle loss without improving output.

2. Core Box and Tooling Cost

Hot box technology uses heated metal core boxes, so tooling cost is higher than cold box. However, service life is much longer.

Typical tooling cost:

- Simple core box: USD 2,000 – 5,000

- Medium complexity: USD 5,000 – 15,000

- Large automotive core box: USD 20,000+

Engineering advantage:

- Stable thermal expansion control

- Excellent core surface finish

- Long service life

Over years of operation, longer tooling life significantly reduces replacement frequency.

3. Energy Consumption Cost

Heating is the main energy expense in hot box core making.

Typical parameters:

- Heating power per core box: 5 – 30 kW

- Machine installed power: 10 – 60 kW

- Working temperature: 200 – 280°C

Compared with cold box systems:

- Higher electricity usage

- No amine gas generator

- No gas neutralization or exhaust treatment system

Practical balance:

Fast curing and short cycle time increase hourly output, offsetting higher heating power cost.

4. Resin Binder Consumption Cost

Hot box processes use thermosetting resin binders.

Typical process data:

- Binder addition: 1.5% – 2.5% of sand weight

- Sand recycling ratio: 85% – 95% with reclamation system

- Core bending strength: ≥ 2.0 MPa

Hidden cost advantage:

- No catalyst gas consumption

- No amine odor treatment system

- Lower environmental investment

In long-term operation, environmental equipment savings are very significant.

5. Compressed Air Consumption Cost

Sand shooting relies on compressed air.

Typical operating conditions:

- Air pressure: 0.5 – 0.8 MPa

- Air consumption: 0.5 – 2.0 m³ per shot

Optimization methods I often recommend:

- Proper air tank sizing

- Fast-response pneumatic valves

- Leak-free pipeline layout

These measures typically reduce compressor power consumption by 10–20%.

6. Labor and Automation Cost

This is where hot box technology really shows its strength.

Labor comparison:

- Manual core making: 2–3 operators

- Automatic hot box line: 1 operator or unmanned

Automation options:

- Automatic core ejection

- Conveyor transfer

- Robot pick-and-place

- PLC recipe control

Result:

Lower labor dependency, fewer human errors, and more stable production.

7. Maintenance and Spare Parts Cost

Hot box machines have relatively simple mechanical and pneumatic systems.

Typical maintenance items:

- Heating element replacement

- Core box sealing strips

- Pneumatic valve servicing

- Temperature sensor calibration

Annual maintenance cost:

Approximately 3–5% of equipment value

Compared with cold box machines, there is no gas generator or exhaust system to maintain — which further reduces long-term costs.

8. Production Efficiency and Scrap Cost

Hot box curing is fast and consistent.

Typical performance:

- Cycle time: 10 – 30 seconds per core

- Scrap rate: ≤ 2% under stable operation

Low scrap directly saves:

- Sand

- Resin

- Labor

- Rework time

Over a year, this becomes a noticeable cost reduction.

9. Environmental and Standards Compliance Cost

Hot box systems produce no amine gas emissions, making compliance much easier.

Relevant international standards:

- ISO 9001 – Quality Management System

- ISO 4414 – Pneumatic System Safety

- EN 1247 – Foundry Machinery Safety

- CE Machinery Directive 2006/42/EC

Standards-based equipment design ensures safe operation, export compliance, and lower environmental inspection risks.

Total Cost of Ownership Overview

| Cost Factor | Hot Box Core Shooting Machine |

|---|---|

| Initial equipment investment | Medium |

| Core box tooling cost | Higher |

| Energy consumption | Higher |

| Resin binder cost | Medium |

| Gas treatment system | None |

| Automation potential | High |

| Scrap rate | Low |

| Maintenance cost | Low |

| Environmental compliance cost | Low |

Conclusion: A Machine That Pays Back in Real Production

From an engineering cost perspective, a hot box core shooting machine is not simply an equipment purchase — it is a long-term production asset.

Yes, heating energy and tooling cost are higher. But savings in gas treatment systems, automation labor, environmental compliance, and low scrap rate significantly reduce total operating cost over time.

For foundries targeting stable high-volume core production, a properly selected hot box core shooting machine becomes a true profit-generating investment — not just another machine on the shop floor.