Don’t let complex geometries slow down your finishing line.

Selecting a Hanger Type Shot Blasting Machine isn’t just about the hook capacity. If the blast wheels aren’t positioned correctly for your specific workpiece, you’ll end up with “blind spots” and costly manual rework.

Introduction

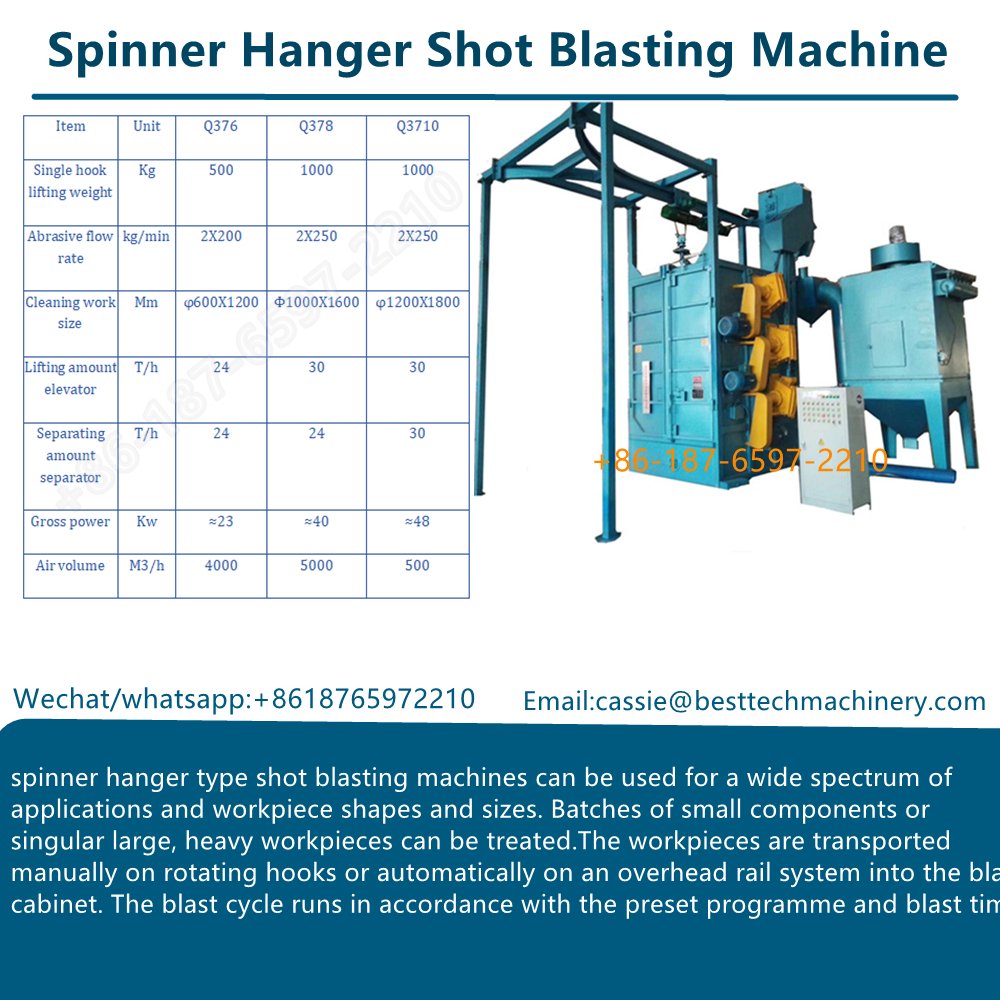

Hanger shot blasting machines are widely used for surface cleaning, rust removal, scale removal, and shot peening of metal workpieces. Typical applications include castings, forgings, welded structures, and heat-treated components.

Compared with tumble or roller conveyor shot blasting machines, hanger type machines are especially suitable for medium to large parts with complex shapes that cannot be rolled or tumbled.

Selecting the correct hanger shot blasting machine is critical for achieving stable cleaning quality, reasonable operating cost, and long equipment service life. This article explains the key selection factors from an engineering and practical production point of view.

1. Workpiece Size, Shape, and Weight

The first and most important factor is the physical characteristics of the workpiece.

Key parameters to confirm:

- Maximum workpiece diameter

- Maximum workpiece height

- Maximum single-piece weight

- Total hanging load per hook

Typical hanger shot blasting machines are designed for:

- Single hook load: 200 – 2,000 kg

- Maximum workpiece height: 800 – 2,500 mm

The hanger structure, lifting mechanism, and rotation system must be designed according to the real production load, not theoretical values.

2. Production Capacity and Throughput

Production volume determines the machine configuration and layout.

Key considerations:

- Required parts per hour

- Average blasting cycle time

- Loading and unloading time

- Single-hook or double-hook design

Double-hook machines allow one hook to blast while the other hook is loading or unloading, significantly improving productivity and reducing idle time.

3. Blast Wheel Quantity and Power

Blast wheels are the core working units of the machine.

Typical selection parameters:

- Blast wheel power: 7.5 – 15 kW per wheel

- Number of wheels: 2 – 8 units

- Shot throwing speed: 70 – 80 m/s

More blast wheels improve coverage and cleaning efficiency, but also increase power consumption and maintenance cost. The wheel layout should match the workpiece shape to avoid blind zones.

4. Workpiece Rotation and Movement Method

Uniform blasting requires proper movement of the workpiece during blasting.

Common designs include:

- Continuous hook rotation

- Adjustable rotation speed

- Optional vertical or swing movement

Typical rotation speed:

- 2 – 6 rpm, adjustable according to part geometry

Correct rotation prevents shadow areas and ensures consistent surface quality.

5. Shot Media Type and Blasting Intensity

Different surface requirements require different shot media.

Common shot media:

- Steel shot (S330, S390)

- Steel grit (G25, G40)

- Mixed shot and grit

Key parameters:

- Shot flow rate

- Media size

- Impact intensity

Proper shot selection balances cleaning efficiency, surface roughness, and wear rate of machine parts.

6. Wear Protection Design

Hanger shot blasting machines operate under high abrasion conditions.

Key wear protection areas:

- Blast chamber liners

- Blast wheel blades

- Control cages

- Shot distribution pipes

Typical liner materials:

- High manganese steel

- Chromium alloy steel

- Rubber liners (optional)

Good wear protection design significantly reduces downtime and spare parts cost.

7. Dust Collection and Environmental Control

Shot blasting produces large amounts of dust and fine particles.

Engineering requirements:

- High-efficiency cartridge or bag filter dust collector

- Proper air volume matching blast chamber

- Dust emission meeting local regulations

- Fully sealed blasting chamber

Environmental performance is especially important for export-oriented projects and modern factories.

8. Automation and Control System

Modern hanger shot blasting machines use PLC-based control systems.

Typical features include:

- Touch screen HMI

- Automatic blasting time control

- Hook rotation speed adjustment

- Fault alarm and safety interlock

- Data monitoring (optional)

Automation improves process stability and operator safety.

9. Installation Space and Workshop Layout

Before final selection, the available workshop space must be evaluated.

Consider:

- Machine footprint

- Hook travel path

- Maintenance access space

- Dust collector installation position

Early layout planning avoids installation difficulties and later modifications.

10. Safety and Standards Compliance

The hanger shot blasting machine should comply with international standards and regulations:

- ISO 9001 – Quality Management System

- EN 1247 – Foundry Machinery Safety

- CE Machinery Directive 2006/42/EC

- ISO 13849 – Safety-related Control Systems

Compliance ensures safe operation and smooth acceptance for overseas markets.

Conclusion

Selecting a hanger shot blasting machine requires comprehensive evaluation of workpiece characteristics, production capacity, blasting configuration, environmental requirements, and safety standards.

From an engineering perspective, the most suitable machine is the one that matches actual production needs, provides stable surface quality, and maintains reasonable operating and maintenance costs.

A correct selection ensures long-term production efficiency, consistent cleaning quality, and reliable equipment performance.