Unlock 360° Surface Perfection: Why the Hanger Shot Blaster is a Metalworking Essential.

In high-precision manufacturing, not every part can handle the “tumble.” For complex, fragile, or heavy components, the Hanger Shot Blasting Machine offers a level of care and coverage that other methods simply can’t match.

Introduction

In metalworking and manufacturing industries, surface preparation is a critical process step. Rust, scale, welding slag, and surface contaminants must be removed before coating, painting, machining, or assembly.

Among various surface treatment solutions, the hanger shot blasting machine is widely recognized as an efficient and reliable system for cleaning medium to large workpieces, especially those with complex shapes.

Hanger shot blasting machines provide stable cleaning quality, high productivity, and long-term cost advantages for modern fabrication and foundry plants.

This article introduces the key advantages of using hanger shot blasting machines in industrial production.

1. High Efficiency Surface Cleaning for Complex Workpieces

One major advantage of hanger shot blasting machines is their ability to clean complex-shaped parts effectively.

Typical workpieces include:

- Large castings

- Forged components

- Welded steel structures

- Heat-treated parts

The workpieces are suspended on rotating hooks, allowing steel shot to reach multiple angles and reduce shadow areas.

Typical blasting performance:

- Blast wheel speed: 70–80 m/s

- Cleaning cycle time: 2–8 minutes

This makes hanger machines ideal for heavy-duty surface preparation.

2. Improved Surface Quality and Consistent Results

Hanger shot blasting provides uniform cleaning and controlled surface roughness.

Benefits include:

- Stable surface cleanliness (Sa 2.5 level achievable)

- Better coating adhesion

- Reduced manual grinding work

Consistent blasting results improve final product appearance and reduce defect rates in coating processes.

3. Suitable for Medium and Large Heavy Parts

Unlike tumble blast machines, hanger type machines can handle large and heavy workpieces without damage.

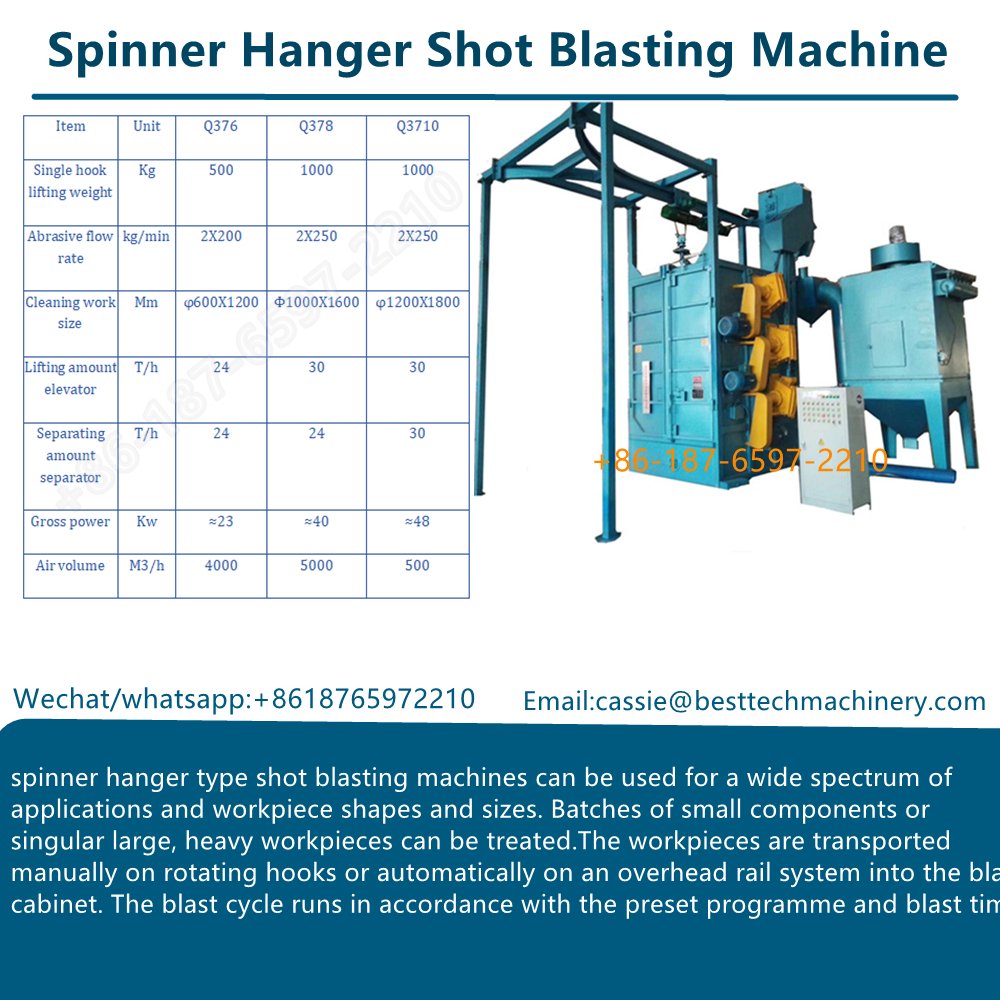

Typical hook load capacity:

- 200 – 2,000 kg per hook

This allows safe blasting of parts that cannot be rolled or tumbled, such as frames, housings, and structural components.

4. Flexible Production for Multiple Product Types

Hanger shot blasting machines are widely used in jobbing foundries and fabrication workshops where product variety is high.

Key flexibility advantages:

- Different workpieces can be hung easily

- Adjustable blasting time and intensity

- Suitable for small batch and mixed production

Double-hook designs further improve throughput by allowing loading and blasting simultaneously.

5. Reduced Labor Cost and Improved Automation

Modern hanger shot blasting machines can be integrated with automation systems.

Typical automation features:

- PLC control with touch screen HMI

- Automatic blasting cycle control

- Hook rotation speed adjustment

- Robot loading/unloading options

Automation reduces operator workload and ensures stable process control.

6. Effective Rust Removal and Coating Preparation

For manufacturing industries, blasting is often required before:

- Painting

- Powder coating

- Galvanizing

- Thermal spraying

Shot blasting removes rust and scale efficiently while creating the proper anchor profile for coating adhesion.

Engineering note:

Correct surface preparation directly increases coating life and corrosion resistance.

7. Long-Term Cost Efficiency and Durable Design

Although hanger shot blasting machines require initial investment, they provide strong long-term economic benefits.

Cost-saving factors:

- Lower manual cleaning requirement

- Reduced rework and coating failures

- Long service life of blast chamber structure

- Replaceable wear liners protecting main body

Key wear parts include:

- Blades

- Control cages

- Liners

With proper maintenance, machines can operate reliably for many years.

8. Environmental Control and Workshop Safety

Modern hanger shot blasting systems are equipped with high-efficiency dust collectors.

Environmental advantages:

- Reduced dust emission

- Cleaner workshop air

- Compliance with local regulations

Typical systems use cartridge or bag filters to maintain stable dust control.

9. Compliance with International Standards

Industrial hanger shot blasting machines are generally designed according to global safety and quality standards:

- ISO 9001 – Quality Management

- EN 1247 – Foundry Machinery Safety

- CE Machinery Directive 2006/42/EC

- ISO 13849 – Safety Control Systems

Standards compliance ensures reliable operation and suitability for export markets.

Conclusion

From an engineering and manufacturing perspective, hanger shot blasting machines offer significant advantages in surface cleaning efficiency, workpiece flexibility, automation compatibility, and long-term cost performance.

They are especially suitable for medium to large workpieces with complex geometries, providing consistent surface quality for coating, painting, and further processing.

For metalworking and manufacturing industries seeking stable surface preparation and high productivity, the hanger shot blasting machine remains one of the most practical and reliable solutions.