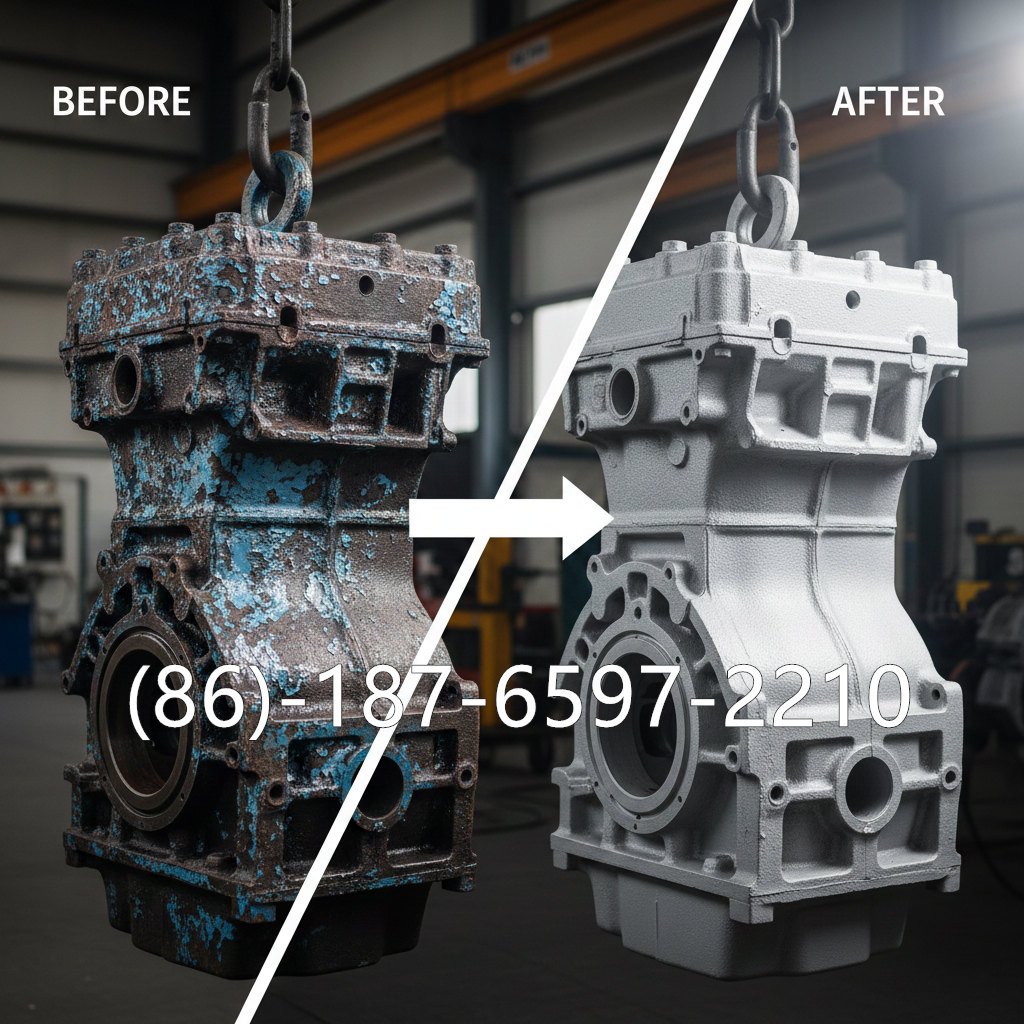

Achieve a Flawless Finish: The Hanger Shot Blaster for Superior Paint & Rust Removal.

In industrial coatings, the foundation is everything. If your surface preparation isn’t perfect, even the best paint won’t last. The Hanger Shot Blasting Machine is engineered to deliver the ultimate clean, setting the stage for long-lasting corrosion protection.

Why it’s your go-to solution for Paint & Rust Removal?

Introduction

In metalworking and manufacturing industries, surface preparation is one of the most important steps before painting, coating, welding, or assembly. Old paint layers, rust, scale, and surface contaminants must be removed completely to ensure product quality and long-term corrosion resistance.

Traditional manual grinding or chemical cleaning methods are often inefficient, labor-intensive, and inconsistent. Therefore, many factories choose the hanger shot blasting machine as an ultimate solution for fast and reliable paint and rust removal.

From an engineering point of view, hanger shot blasting technology provides stable cleaning quality, high productivity, and cost-effective operation for medium to large metal workpieces.

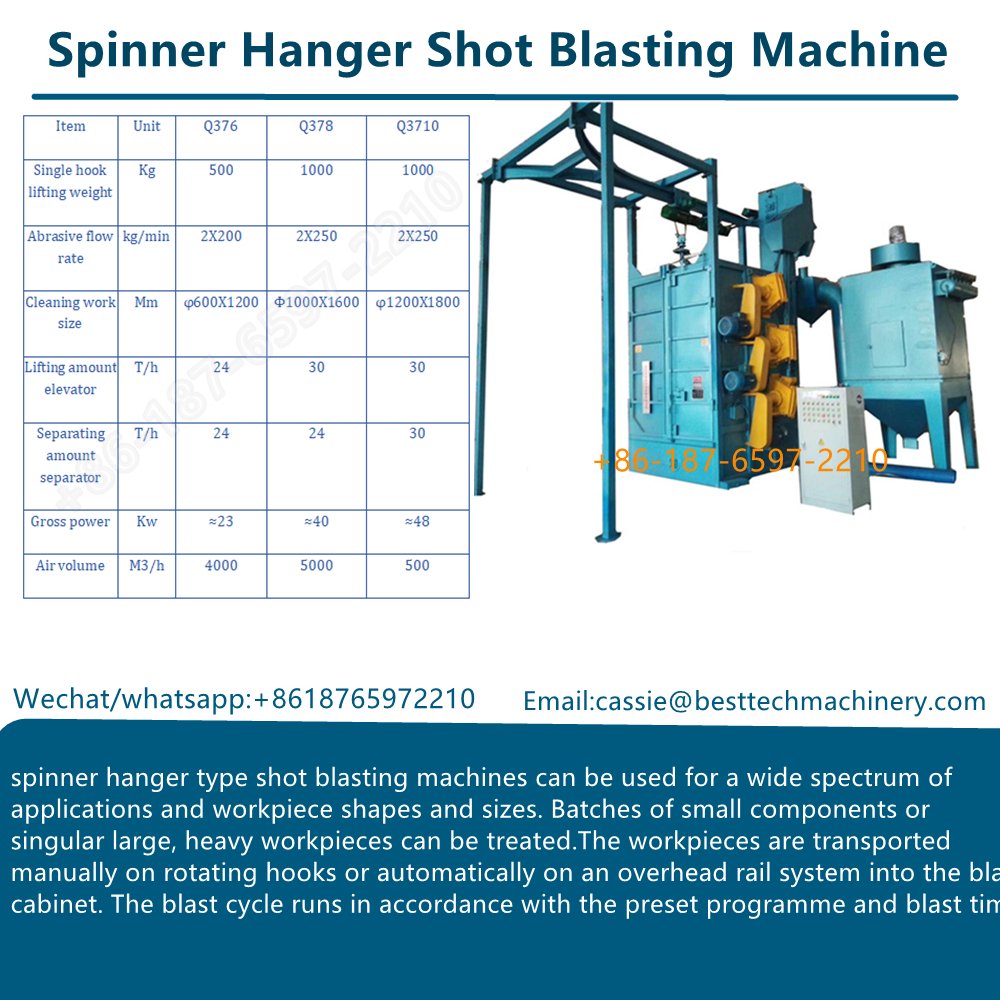

1. What Is a Hanger Shot Blasting Machine?

Hanger shot blasting machine is a type of surface treatment equipment where workpieces are suspended on rotating hooks inside a blasting chamber.

Steel shot or grit is thrown at high speed by blast wheels to remove:

- Rust layers

- Old paint coatings

- Oxide scale

- Welding slag

- Surface impurities

Typical machine configuration:

- Single-hook or double-hook design

- Multiple blast wheels for full coverage

- Automatic abrasive recycling system

- Dust collector for environmental control

2. Why Shot Blasting Is the Best Method for Paint and Rust Removal

Shot blasting provides mechanical cleaning by high-speed abrasive impact.

Compared with chemical stripping or manual cleaning, shot blasting offers:

- Faster cleaning speed

- Uniform surface treatment

- No chemical waste

- Better surface roughness for repainting

Typical blasting performance:

- Blast wheel speed: 70–80 m/s

- Cleaning cycle time: 2–10 minutes

- Surface cleanliness: Sa 2.5 achievable

This makes hanger shot blasting an ideal method for industrial paint and rust removal.

3. Key Advantages for Paint and Rust Removal Applications

3.1 High Cleaning Efficiency

Blast wheels provide strong impact energy, quickly removing thick rust and old paint layers.

Typical blast wheel power:

- 7.5 – 15 kW per wheel

Multiple wheels ensure full surface coverage.

3.2 Uniform Surface Preparation for Repainting

After blasting, the metal surface becomes clean and slightly rough, improving coating adhesion.

Benefits include:

- Longer paint service life

- Reduced coating peeling risk

- Improved corrosion resistance

Engineering note:

Proper surface preparation is the foundation of high-quality painting.

3.3 Suitable for Complex and Large Workpieces

Hanger machines are designed for parts that cannot be tumbled or rolled.

Typical workpieces:

- Steel structures

- Frames and chassis

- Large castings

- Fabricated components

Hook load capacity:

- 200 – 2,000 kg per hook

Rotation ensures uniform blasting without shadow areas.

3.4 Reduced Labor and Operating Cost

Shot blasting replaces heavy manual grinding work, reducing labor intensity.

Automation options:

- PLC control system

- Adjustable blasting cycle

- Robot loading/unloading

This improves productivity and reduces long-term operating cost.

3.5 Durable Wear Protection Design

Paint and rust removal requires strong blasting intensity, so wear protection is critical.

Key wear parts:

- Blast wheel blades

- Control cages

- Chamber liners

Liner materials:

- High manganese steel

- Chromium alloy steel

- Rubber liners (optional)

With proper maintenance, machine service life is long and stable.

4. Typical Industries Using Hanger Shot Blasting Machines

Hanger shot blasting machines are widely used in:

- Steel fabrication plants

- Foundries and casting workshops

- Automotive parts manufacturing

- Shipbuilding and offshore structures

- Construction machinery production

- Pipeline and pressure vessel industries

In all these industries, rust and paint removal is essential for surface quality control.

5. Environmental and Safety Considerations

Modern hanger shot blasting machines are equipped with efficient dust collection systems.

Key environmental features:

- Cartridge or bag filter dust collector

- Sealed blasting chamber

- Reduced dust emission in workshop

Machines are generally designed according to international standards:

- ISO 9001 – Quality Management

- EN 1247 – Foundry Machinery Safety

- CE Machinery Directive 2006/42/EC

- ISO 13849 – Safety Control Systems

Compliance ensures safe and reliable operation.

Conclusion

For metalworking and manufacturing industries, removing rust and old paint efficiently is a key requirement for high-quality coating and long-term corrosion protection.

From an engineering perspective, the hanger shot blasting machine provides an ultimate solution by offering:

- Fast and uniform cleaning

- Excellent surface preparation

- Capability for large and complex workpieces

- Reduced labor cost and automation potential

- Long-term cost-effective operation

With proper machine selection and maintenance, hanger shot blasting technology remains one of the most reliable and efficient methods for industrial paint and rust removal.