In the race for foundry automation, the Cold Box Core Shooting Machine remains the undisputed champion for high-volume production. But what exactly gives it the edge over Hot Box or Shell molding?

Cold box core shooting machine is a foundry machine used to produce sand cores by shooting resin-coated sand into a core box and hardening it instantly using amine gas curing at room temperature.

Introduction

In modern foundry production, sand cores are essential for forming internal cavities and complex structures in castings. Core quality directly affects casting dimensional accuracy, surface finish, and defect rate. As foundries pursue higher productivity and stable quality, traditional CO₂ or manual core-making methods often fail to meet current production requirements.

The Cold Box Core Shooting Machine has become one of the most widely adopted core-making solutions in global foundries due to its extremely fast curing speed, high core strength, excellent dimensional accuracy, and strong automation compatibility. From an engineering perspective, this technology provides significant advantages in both production efficiency and total operating cost.

This article explains the main advantages of using a cold box core shooting machine in foundry operations.

1. Extremely Fast Core Curing Speed

Cold box technology uses amine gas to cure resin-coated sand at room temperature. Chemical reaction hardens the core within seconds, achieving very short production cycles.

Typical Process Parameters

- Amine gas curing time: 1 – 5 seconds

- Full core hardening time: 10 – 20 seconds

- Production output: 60 – 200 cores/hour

Engineering Advantage

Fast curing speed dramatically increases core production capacity, making cold box machines ideal for medium and large-scale foundries.

2. High Core Strength and Dimensional Accuracy

Cold box resin forms strong chemical bonding between sand grains, resulting in excellent mechanical performance.

Typical Core Performance

- Core bending strength: ≥ 2.5 MPa

- Dimensional tolerance: ±0.1 mm

- Smooth and dense core surface

Engineering Benefit

High-strength cores resist breakage during handling and molten metal pouring, reducing casting defects such as sand inclusion and core shift.

3. Excellent Sand Flowability and Mold Filling

Cold box sand mixtures have good flowability, ensuring complete filling of complex core box cavities.

Engineering Results

- Uniform internal sand density

- No soft or hollow areas

- Sharp and clear core edges

This is especially important for thin-wall, long-passage, and multi-cavity cores.

4. No Heating System Required

Unlike hot box technology, cold box machines do not require heated core boxes.

Cost and Energy Advantages

- No electric heating system

- Lower installed machine power

- No thermal expansion stress on tooling

This significantly reduces energy consumption and extends core box service life.

5. Flexible Production and Quick Tool Change

Cold box machines allow rapid change of core boxes without heating or cooling time.

Engineering Benefits

- Short setup time

- Easy small-batch production

- Flexible multi-product switching

This feature is especially valuable for jobbing foundries and customized casting production.

6. High Automation and Integration Capability

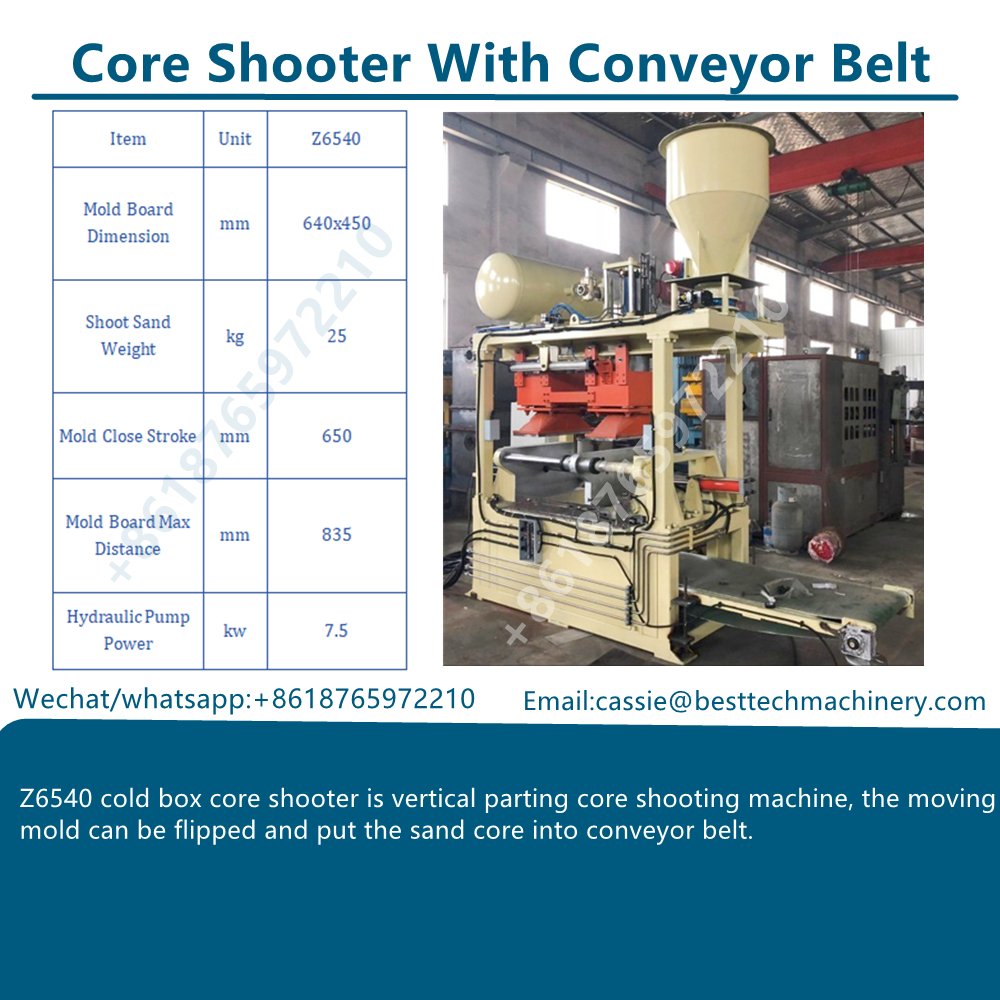

Cold box core shooting machines are easy to integrate into automated production lines.

Automation Options

- Automatic sand feeding

- Automatic core ejection

- Conveyor or robot handling

- PLC + HMI control system

Engineering Advantage

Automation reduces labor dependency, improves production consistency, and stabilizes output rhythm.

7. Stable and Repeatable Process Control

Cold box systems use accurate resin dosing and gas injection control.

Key Control Parameters

- Resin dosing accuracy: ±0.1%

- Amine gas injection time accuracy: ±0.1 second

- Core hardness repeatability: Stable within ±3%

Engineering Result

Consistent process control ensures low scrap rate and reliable core quality.

8. Suitable for Large and Complex Cores

Cold box technology is widely used for large and complicated cores.

Typical Applications

- Automotive engine block water jacket cores

- Cylinder head cores

- Pump and valve body cores

- Pipe fitting internal cores

Complex internal cavity cores are easier to produce with cold box technology.

9. Lower Core Box Tooling Cost

Cold box core boxes do not require internal heating channels.

Engineering Advantage

- Simpler box structure

- Lower tooling manufacturing cost

- Easier maintenance and repair

This reduces initial tooling investment compared with hot box technology.

10. Environmental Performance and Standards Compliance

Cold box machines meet modern environmental and safety requirements when equipped with proper gas treatment units.

Applicable International Standards

- ISO 9001 – Quality Management System

- ISO 4414 – Pneumatic Fluid Power Safety Standard

- EN 1247 – Foundry Machinery Safety Standard

- CE Machinery Directive 2006/42/EC

Standards-based design ensures safe operation, export compliance, and stable long-term use.

Advantages Summary

| Feature | Cold Box Core Shooting Machine |

|---|---|

| Curing speed | Extremely fast |

| Core strength | Very high |

| Dimensional accuracy | Excellent |

| Energy consumption | Low |

| Tooling cost | Lower than hot box |

| Automation capability | High |

| Production flexibility | Excellent |

| Suitable for complex cores | Yes |

| Process stability | Very stable |

| Environmental compliance | Good with gas treatment |

Conclusion

From an engineering perspective, the Cold Box Core Shooting Machine provides an ideal solution for modern foundries requiring high core production efficiency, strong core strength, excellent dimensional accuracy, and flexible manufacturing. Its fast curing speed, low energy demand, automation readiness, and stable process control significantly reduce production cost while improving casting quality.

With proper equipment selection and process management, a cold box core shooting machine becomes a long-term reliable core production system for competitive foundry operations.