Working Principle of the Tumble Belt Shot Blasting Machine

The tumble belt shot blasting machine is mainly designed for cleaning small to medium-sized workpieces that can roll or tumble during processing. The workpieces are placed on a rubber or steel belt, and as the belt rotates, the parts continuously turn over. At the same time, high-speed blasting wheels throw steel shots onto the moving parts.

Because the parts are tumbling, every surface can be evenly exposed to the shot stream. This ensures consistent cleaning without blind spots. By selecting different shot sizes and controlling the blasting time, we can achieve descaling, derusting, deburring, or surface hardening according to production needs.

The machine typically includes:

- Blasting chamber with wear-resistant lining plates.

- Tumble belt conveyor for circulating parts.

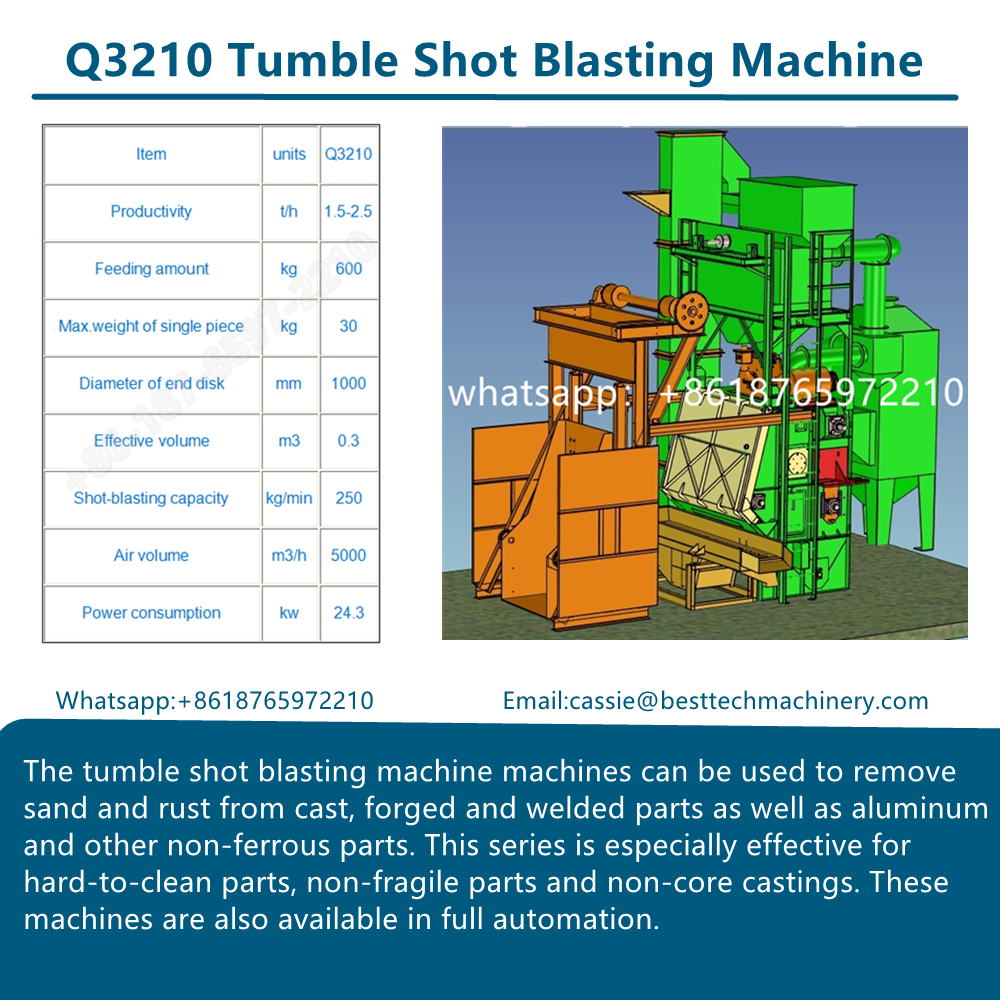

- High-efficiency blasting wheels (throwing capacity usually 100–250 kg/min each).

- Abrasive recycling and separation system to keep shots clean and reduce wear.

This type of equipment is suitable for batch production, especially when handling small castings, forgings, or heat-treated components.

Application Range of the Tumble Belt Shot Blasting Machine

Metal Manufacturing

In foundries and metalworking shops, the tumble belt shot blasting machine is often used to clean cast iron or steel parts after shakeout. Oxide scale, sand, and small burrs can be removed quickly, giving the parts a uniform finish before machining or coating.

For aluminum parts, blasting also helps improve corrosion resistance and paint adhesion.

Automotive Industry

Automotive plants use tumble belt shot blasting machines for cleaning components such as gear blanks, connecting rods, brackets, and fasteners. Because the process is continuous and parts are evenly rolled, the surface roughness after blasting is stable, which is critical for paint coating or subsequent machining.

Compared with manual cleaning, the machine ensures consistent quality and reduces labor intensity.

Aerospace Components

Although aerospace parts often require more precise handling, small steel or titanium components that can withstand tumbling—such as fasteners and brackets—are still processed with tumble belt machines. The blasting process improves fatigue strength by creating compressive stress on the surface, which is important for safety-critical components.

Machinery Manufacturing

General machinery workshops use tumble belt blasting machines to clean welded or forged parts in batches. For example, small gears, valves, or hardware components are cleaned to remove welding slag and oxide before assembly or coating. This improves the service life of the equipment and reduces the chance of premature corrosion.

Conclusion

From casting workshops to automotive factories, tumble belt shot blasting machines are widely adopted for batch cleaning of small and medium parts. Their advantage lies in uniform cleaning, stable performance, and suitability for mass production. For manufacturers dealing with high volumes of small castings or forged pieces, this equipment offers an efficient and reliable surface preparation solution.