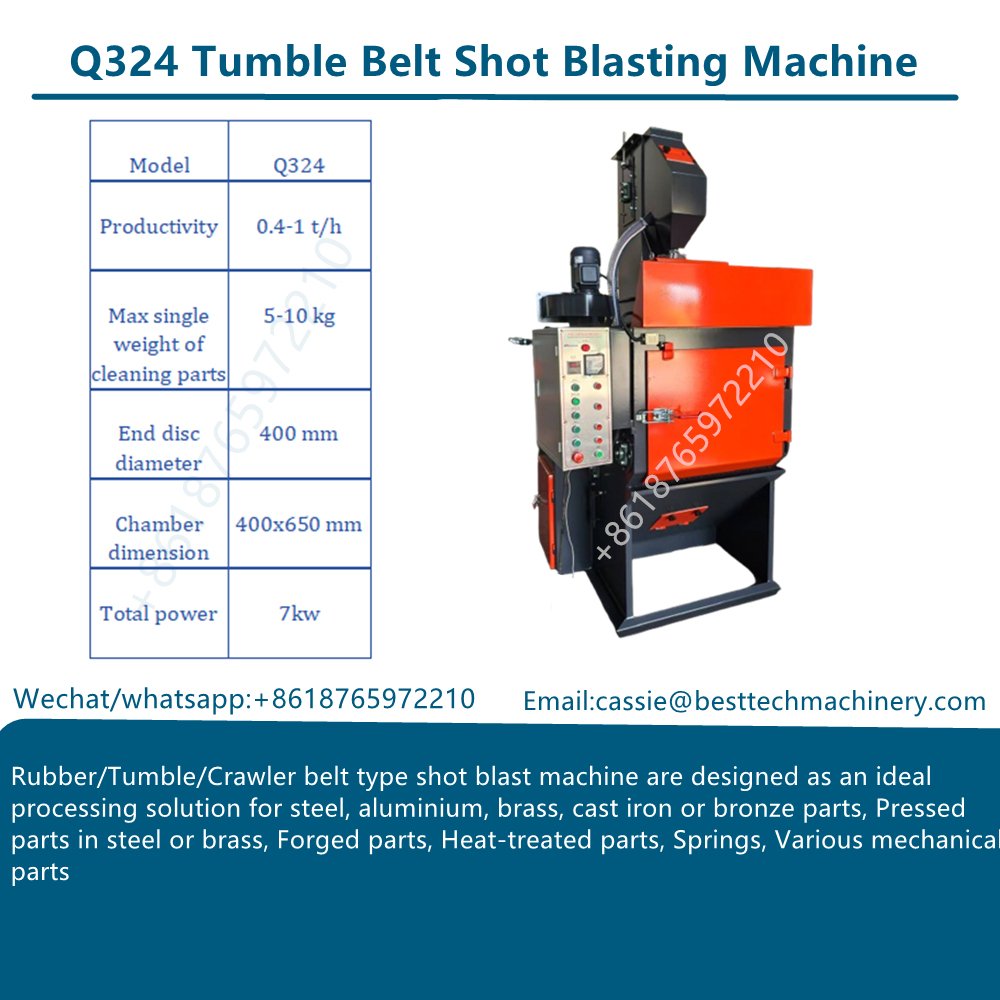

The batch-type tumble shot blaster with a rubber or steel belt is a widely used surface preparation machine designed for cleaning, descaling, and deburring a wide range of small to medium-sized workpieces. Its tumbling action ensures even exposure to the blast stream, delivering consistent results for industries such as automotive, foundry, forging, and metalworking.

What Is A Tumble Shot Blaster?

A tumble shot blaster is an industrial surface preparation machine designed to clean, descale, or deburr small to medium-sized workpieces by combining tumbling motion with high-velocity abrasive blasting. It is widely used in foundries, forges, metalworking shops, and manufacturing plants to improve surface quality before coating, painting, or further processing.

How It Works

The machine features a continuous loop belt made of either rubber (for delicate or non-ferrous parts) or steel (for heavier, abrasive-tolerant components). Workpieces are loaded into the blasting chamber and placed on the moving belt. As the belt rotates, the parts gently tumble over each other, ensuring all surfaces are evenly exposed to high-velocity abrasive media propelled by one or more blast wheels.

After blasting, the machine automatically separates the cleaned parts from residual abrasive, and dust is collected by the integrated dust collector.

Key Features

- Choice of Belt Material

- Rubber Belt: Ideal for lighter, non-ferrous, or more delicate parts, reducing the risk of damage.

- Steel Belt: Suited for heavy-duty cleaning of steel, iron, or cast parts.

- Uniform Cleaning

Tumbling ensures that every surface, edge, and cavity receives equal blasting coverage. - Batch Operation

Flexible processing of various part sizes and shapes within a single batch. - Durable Construction

High-strength wear-resistant materials prolong the lifespan of the machine. - Efficient Dust Collection

Integrated dust filtration system maintains a clean working environment.

Applications

- Casting and Foundry – Removing sand, scale, and oxidation from cast components.

- Forging and Heat Treatment – Cleaning forged parts, removing scale after heat treatment.

- Metal Fabrication – Deburring and surface texturing for improved coating adhesion.

- Non-Ferrous Industries – Cleaning aluminum, brass, or zinc parts with minimal damage (rubber belt type).

Advantages

- High throughput for small and medium-sized parts.

- Gentle yet effective tumbling action for complete surface coverage.

- Versatility to handle a wide range of part geometries.

- Reduced labor costs with automated loading, blasting, and unloading.

Why Choose a Tumble Shot Blaster? – Reliable, Efficient, and Cost-Effective Surface Preparation

A tumble shot blaster is one of the most versatile and efficient machines for cleaning, descaling, and deburring small to medium-sized workpieces. Its unique tumbling action combined with high-speed abrasive blasting ensures that every part is cleaned thoroughly and consistently. Choosing a tumble shot blaster offers several key advantages for manufacturers and metal processors.

1. Uniform Cleaning Quality

The tumbling action continuously turns the workpieces during blasting, ensuring all sides, edges, and corners are exposed to the blast stream. This results in consistent surface preparation, ideal for painting, coating, or further processing.

2. High Efficiency and Throughput

Tumble shot blasters can process a large number of parts in a single batch, reducing cycle times and increasing productivity. This makes them ideal for mass production environments such as foundries, forging plants, and automotive component manufacturing.

3. Versatility for Different Materials

With the option of rubber or steel belts, the machine can handle a wide variety of materials:

- Rubber belt – Gentle on aluminum, brass, and other delicate parts.

- Steel belt – Perfect for heavy-duty cleaning of steel, iron, and other robust components.

4. Cost-Effective Operation

The automated process reduces the need for manual labor, lowers cleaning time, and minimizes rework. Its robust design ensures low maintenance costs and a long service life.

5. Compact Design for Easy Integration

Tumble shot blasters have a relatively small footprint, making them easy to integrate into existing production lines or use as standalone cleaning stations.

6. Cleaner and Safer Working Environment

Built-in dust collection systems keep the workspace free of airborne dust, ensuring better safety and compliance with environmental regulations.

Applications Where It Excels

- Removing sand and scale from castings.

- Cleaning forged parts after heat treatment.

- Deburring stamped or machined components.

- Preparing surfaces for coating or painting.

Choosing a tumble shot blaster means investing in reliable performance, uniform quality, and cost savings. Whether you process delicate non-ferrous components or heavy-duty steel parts, this machine delivers outstanding results while improving productivity and operational efficiency.

Conclusion

The batch-type tumble shot blaster with rubber or steel belt combines efficiency, durability, and flexibility in one compact system. Whether your priority is heavy-duty descaling or gentle cleaning of delicate parts, choosing the right belt type allows you to optimize performance, extend part lifespan, and improve surface quality for downstream processes.