Sand mixers are essential equipment in foundry operations, playing a crucial role in preparing molding sand with consistent quality. These machines blend sand, clay, water, and additives to create homogeneous mixtures for casting molds.

Introduction to Sand Mixers

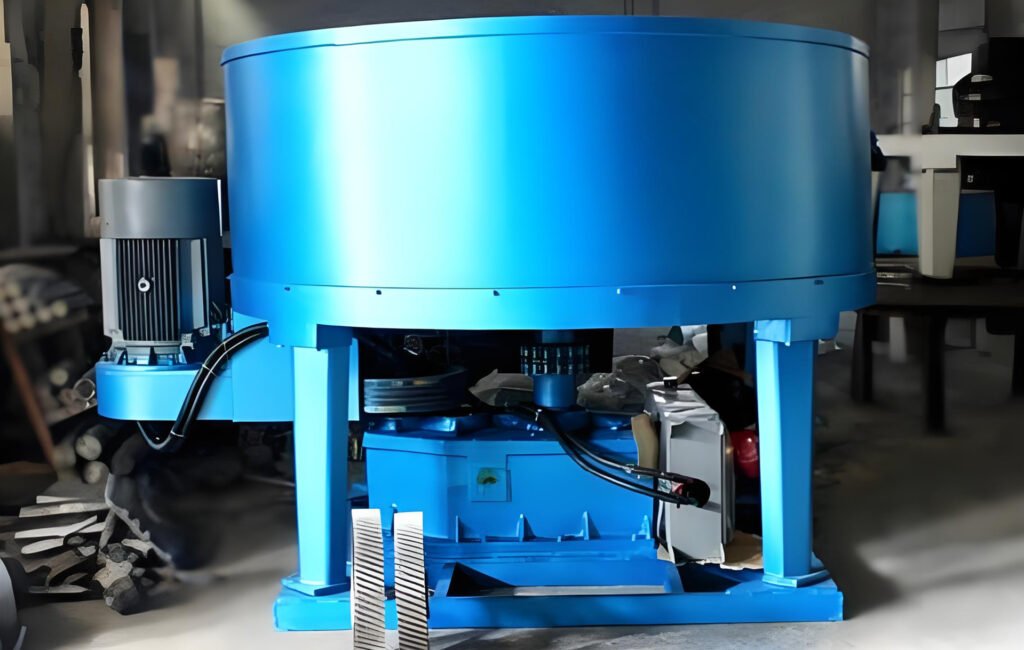

Sand mixers, also known as sand mullers, are mechanical devices designed to thoroughly combine various components to produce uniform molding sand. They come in different configurations including batch mixers and continuous mixers, each serving specific production needs.

What Is A Sand Mixer?

A sand mixer, often also called a sand muller, is a specialized piece of industrial equipment designed for one primary purpose: to thoroughly and uniformly blend dry or moist granular materials, primarily sand, with binding agents (like clay or resin), water, and other additives.

Why is this Important?

- Foundry Core: In metal casting foundries, creating molds and cores requires sand mixtures with precise consistency. The sand must hold its shape when packed around a pattern but also break away cleanly after the metal solidifies. A sand mixer ensures the clay (bentonite), water, and sand are evenly distributed and the mixture has the right moisture content and “flowability” (known as “green strength” for green sand).

- Construction & Other Industries: Sand mixers are also used to prepare mortars, specialized cement blends, ceramic slurries, and other mixtures where sand is a key component and uniform distribution of binders and moisture is critical.

Working Principle

The typical sand mixer operates through:

- A rotating pan or drum

- Mulling wheels or blades that knead the mixture

- Scraper blades that prevent material buildup

- Water/chemical additive injection systems

The mixing action combines both shearing and compression forces to achieve complete homogenization of the sand mixture.

Key Applications

1. Conventional Green Sand Molding

- Produces standard green sand mixtures (85-90% sand, 7-10% clay, 3-5% water)

- Used for manual or machine molding processes

- Creates molds for iron, steel, and non-ferrous castings

- Suitable for small to medium production runs

2. High-Pressure Molding Systems

- Prepares sand for automated molding machines

- Requires more consistent mixture properties

- Demands precise control of moisture content

- Used in DISAMATIC and similar molding lines

3. Flaskless Molding Applications

- Produces sand for vertical and horizontal flaskless systems

- Requires higher green strength mixtures

- Must maintain consistency for tight tolerances

- Common in automotive component production

Advantages of Modern Sand Mixers

- Consistent mixture quality

- Reduced binder consumption

- Lower energy consumption compared to manual mixing

- Automated control systems for precise formulations

- Reduced labor requirements

Maintenance Considerations

Proper maintenance ensures long mixer lifespan:

- Regular inspection of blades/wheels

- Timely replacement of worn components

- Proper lubrication of moving parts

- Cleaning to prevent material buildup

Future Trends

The industry is moving toward:

- Smart mixing systems with IoT integration

- AI-powered mixture optimization

- More energy-efficient designs

- Improved wear-resistant materials

As manufacturing demands grow more sophisticated, sand mixers continue to evolve, offering foundries and other industries reliable solutions for their material preparation needs.

Why Sand Mixers Remain Essential in Modern Foundries

Introduction to Foundry Sand Preparation

Modern foundries rely on precisely prepared molding sand to produce high-quality metal castings. Sand mixers serve as the cornerstone of this preparation process, ensuring consistent mixture quality that directly impacts casting outcomes.

Key Advantages of Modern Sand Mixers

1. Superior Mixture Consistency

- Achieves homogeneous distribution of binders (clay/resin)

- Ensures even moisture content throughout the batch

- Eliminates pockets of inconsistent composition

- Produces repeatable results batch after batch

2. Enhanced Mold Quality

- Develops optimal green strength for pattern removal

- Creates proper permeability for gas escape

- Maintains stability during metal pouring

- Ensures clean collapsibility after solidification

3. Operational Efficiency

- Reduces mixing time compared to manual methods

- Lowers energy consumption per batch

- Minimizes binder material waste

- Decreases labor requirements

4. Advanced Process Control

- Digital monitoring of mixing parameters

- Precise additive injection systems

- Recipe memory for different sand types

- Integration with foundry management systems

5. Cost-Effectiveness

- Longer equipment lifespan with proper maintenance

- Reduced casting defects and scrap rates

- Lower maintenance requirements than alternative systems

- Better utilization of raw materials

Technological Advancements

Modern sand mixers incorporate:

- IoT-enabled performance monitoring

- Automated wear detection systems

- Predictive maintenance capabilities

- AI-driven mixture optimization

- Energy recovery systems

Comparison with Alternative Methods

While new technologies emerge, sand mixers outperform:

- Paddle mixers in mixture quality

- Tumble mixers in binder activation

- Continuous mixers in flexibility

- Manual mixing in consistency and speed

Why Use a Sand Mixer Instead of a Regular Mixer?

- Superior Homogeneity: Achieves a level of uniformity essential for consistent mold/core properties.

- Optimal Properties: Develops the necessary strength, permeability, and collapsibility in foundry sands.

- Consistency: Critical for repeatable casting quality and minimizing defects.

- Efficiency: Designed to handle abrasive materials and heavy loads effectively.

In essence, a sand mixer is not just a mixer; it’s a sophisticated machine engineered to “mull” – combining compression, shearing, and blending – to transform raw sand and additives into a precisely controlled, high-performance mixture vital for metal casting and other industrial processes.

Conclusion

The enduring relevance of sand mixers in modern foundries stems from their unmatched ability to produce high-quality molding sand efficiently and cost-effectively. As foundry processes evolve, sand mixers continue to adapt through technological integration while maintaining their fundamental advantages in metal casting operations.