Is your molding line an asset or a hidden cost center?

Many foundries focus only on the initial “Price Tag” of a molding machine. But the real question is: What is the total cost of ownership over 10 years?

Hydraulic Multi Piston Sand Molding Machine is a type of foundry equipment used to produce green sand molds for metal casting. It uses a hydraulic system to drive multiple compaction pistons that press molding sand into a flask, forming a strong and accurate mold cavity.

Our latest cost analysis of the Hydraulic Multi-Piston Sand Molding Machine reveals how this technology pays for itself.

Introduction

In foundry production, selecting molding equipment is not only a question of purchase price. It is a decision related to long-term operating cost, production stability, and casting quality consistency.

The Hydraulic Multi Piston Sand Molding Machine has become a key solution for modern green sand molding lines. Compared with traditional jolt-squeeze or mechanical molding machines, it provides uniform compaction force, stable mold hardness, and higher automation potential.

From the machine manufacturer perspective, a complete cost analysis should consider initial investment, energy consumption, labor requirement, maintenance cost, production efficiency, and scrap reduction. This article provides a practical reference for foundry owners and technical managers.

Initial Investment Cost

The initial investment includes:

- Molding machine body

- Hydraulic power station

- PLC control system

- Pattern plate and flask system

- Sand feeding and leveling device

- Installation and commissioning

Compared with traditional jolt-squeeze molding machines, hydraulic multi piston machines have a higher purchase price. However, their structure is designed for continuous industrial duty with:

- Rigid machine frame

- Low vibration operation

- Long mechanical service life

According to GB/T 16758 – General Technical Conditions for Foundry Molding Machines, hydraulic molding machines are designed for stable long-term load operation. In practice, the higher initial cost is offset by lower failure rate and longer maintenance cycles.

Operating Cost Analysis

Power Consumption

Hydraulic compaction relies on motor-driven oil pumps. Modern hydraulic stations use pressure control valves to supply oil only during compaction, avoiding unnecessary energy waste.

Typical power configuration:

- Motor power: 7.5 – 15 kW

- Output capacity: 40 – 60 molds/hour

When calculated per mold, power consumption cost is small compared with total casting production value.

Hydraulic system design usually follows:

- ISO 4413 – Hydraulic Fluid Power Safety Requirements

- GB/T 3766 – Hydraulic System General Technical Requirements

These standards ensure energy-efficient and safe hydraulic operation.

Labor Cost

Hydraulic multi piston molding machines support semi-automatic and fully automatic molding lines. Normally:

- One operator can manage one molding station

- Manual ramming and impact operations are eliminated

- Operator skill dependency is reduced

Compared with mechanical molding machines, labor cost can be reduced by 30–50% over long-term operation.

Maintenance Cost

Maintenance cost mainly includes:

- Hydraulic oil replacement

- Filter elements

- Sealing rings

- Sensor and electrical inspection

Because compaction is performed by smooth hydraulic pressure rather than mechanical impact:

- Wear on mechanical structure is low

- Foundation vibration damage is eliminated

- Breakdown frequency is reduced

Typical annual maintenance cost is 2–4% of equipment value, which is acceptable for heavy-duty foundry equipment.

Hydraulic system maintenance normally follows:

- ISO 4406 – Hydraulic Oil Cleanliness Standard

- GB/T 14039 – Hydraulic Transmission Oil Cleanliness

Clean oil ensures long service life of hydraulic components.

Production Efficiency and Scrap Reduction Benefit

Multi piston compaction produces uniform mold hardness from surface to bottom. This improves mold stability and reduces casting defects such as:

- Sand inclusion

- Mold collapse

- Dimensional deviation

Typical improvement results:

- Scrap rate reduced from 5% → 2%

- Rework cost significantly reduced

- Casting surface finish improved

Even a 2–3% scrap reduction brings considerable annual savings in medium-sized foundries.

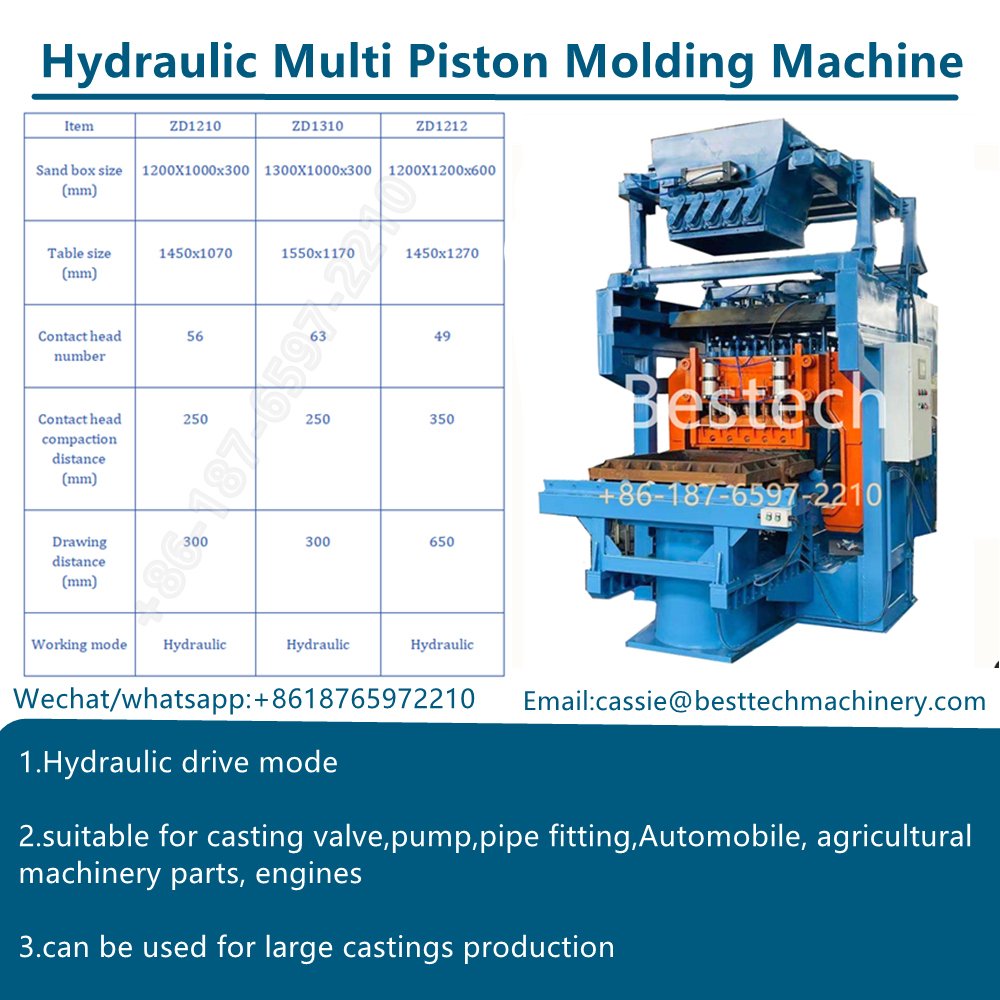

Typical Technical Parameters

Parameters vary according to model and casting requirements.

Return on Investment (ROI) Example

A practical comparison in medium-size foundry:

| Item | Traditional Jolt-Squeeze | Hydraulic Multi Piston |

|---|---|---|

| Molds per hour | 40-60 | 60 |

| Scrap Rate | 5% | 2% |

| Operators | 3 | 1 |

| Mold Hardness | 80-85 HB | 85-95 HB |

| Annual Cost Saving | — | 25–40% |

Most factories recover equipment investment within 12–24 months.

Hidden Cost Advantages

Beyond direct production cost, hydraulic multi piston machines reduce:

- Workshop vibration damage

- Machine foundation repair cost

- Mold inconsistency complaints

- Operator fatigue and safety risks

These hidden savings improve total factory efficiency and management stability.

Applicable International Standards

To ensure safety and performance compliance, hydraulic molding machines commonly follow:

- ISO 12100 – Safety of Machinery

- ISO 4413 – Hydraulic System Safety

- ISO 13849 – Safety Control Systems

- GB/T 16758 – Foundry Molding Machine Technical Conditions

- GB/T 5226.1 – Electrical Safety of Machinery

- JIS B 9700 – Safety of Machinery (Japan)

Following these standards ensures global market acceptance.

Conclusion

From an engineering and management viewpoint, the Hydraulic Multi Piston Sand Molding Machine is not simply equipment — it is a long-term production investment.

Although initial purchase cost is higher, lower labor demand, reduced scrap rate, stable molding quality, and long service life guarantee strong economic return for modern foundries.

Good equipment investment today builds stable profit tomorrow.