The crawler shot blaster is a specialized surface preparation machine designed to clean, descale, and strengthen metal parts by propelling abrasive media using a high-speed rotating blast wheel. Its defining feature is the use of a rubber or manganese steel crawler belt, which allows parts to tumble and expose all surfaces to the blast stream, ensuring thorough treatment.

What is a Crawler Shot Blaster?

A crawler shot blaster is a type of shot blasting machine specifically designed for cleaning and strengthening small to medium-sized workpieces. It uses a rubber or manganese steel crawler belt to tumble parts during the blasting process, ensuring complete and even surface treatment.

How It Works

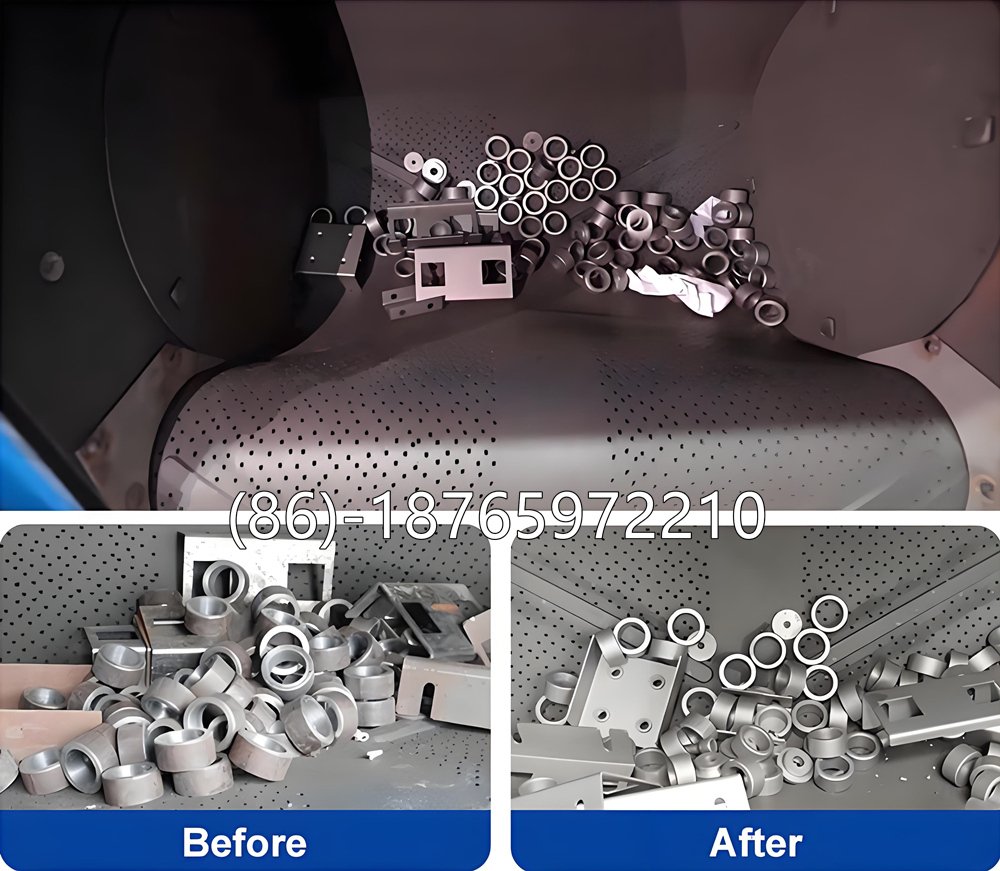

The crawler shot blaster operates by placing workpieces into the machine’s blast chamber. As the blast wheel rotates at high speed, it propels steel shots or grit toward the parts. At the same time, the crawler belt tumbles the workpieces, allowing every surface to be exposed to the abrasive media. This results in thorough cleaning, descaling, or peening of the entire surface.

Key Features of Crawler Shot Blaster

- Durable Crawler Belt System

The crawler belt is highly wear-resistant and capable of handling heavy loads. It rotates to tumble the workpieces, ensuring even and consistent blasting from all angles. - Efficient Blasting Performance

With powerful blast wheels and optimized abrasive flow, the machine removes rust, scale, sand, and burrs efficiently from surfaces of metal parts such as castings, forgings, and heat-treated components. - Batch Processing Capability

Crawler shot blasters are ideal for batch production. Multiple small to medium-sized parts can be cleaned simultaneously, improving productivity and reducing labor costs. - Dust Collection and Environmental Safety

An integrated dust collection system ensures a clean working environment by filtering out abrasive dust and contaminants. - Low Maintenance Design

The machine is engineered for easy maintenance with wear-resistant components and a reliable structure, minimizing downtime and operational costs.

Applications

Crawler shot blasters are widely used in industries such as:

- Foundries: Cleaning cast iron, steel, aluminum castings.

- Automotive: Surface cleaning of engine parts, gear components.

- Forging & Heat Treatment: Descaling and deburring forged and treated parts.

- Metal Fabrication: Pre-paint or coating surface preparation.

Advantages of Using Crawler Shot Blaster

- Thorough Coverage: Tumbling motion exposes all part surfaces for uniform cleaning.

- High Productivity: Suitable for high-volume batch processing.

- Versatile Use: Handles a variety of part shapes and sizes.

- Compact Design: Saves floor space and fits well in various production setups.

Why Choose a Crawler Shot Blaster?

When it comes to efficient and reliable surface preparation, the crawler shot blaster stands out as one of the most practical solutions for cleaning and strengthening small to medium-sized metal parts. It combines powerful abrasive blasting with a unique tumbling system, delivering superior results across a range of industries.

1. Comprehensive Surface Coverage

Unlike stationary or fixed-position machines, the crawler shot blaster uses a rotating crawler belt to continuously tumble parts during blasting. This movement exposes all surfaces of each workpiece to the abrasive stream, ensuring uniform cleaning, descaling, or peening. It’s especially effective for parts with complex geometries or hard-to-reach areas.

2. Efficient Batch Processing

The crawler shot blaster is designed for batch-type production, allowing multiple parts to be processed at once. This reduces downtime and labor intensity while improving throughput, making it ideal for medium to high-volume manufacturing.

3. Durable and Low-Maintenance Design

Built with wear-resistant materials, such as rubber or manganese steel belts and high-quality liners, crawler shot blasters are engineered for long service life. The machine’s layout also ensures easy maintenance and accessibility, minimizing downtime and repair costs.

4. Versatile Applications

Crawler shot blasters can handle a wide variety of workpieces, including:

- Iron, steel, and aluminum castings

- Heat-treated forgings

- Automotive and mechanical components

- Parts with rust, scale, or burrs

This makes them highly adaptable across industries like foundry, automotive, metal fabrication, and heat treatment.

5. Clean and Eco-Friendly Operation

Most crawler shot blasters are equipped with advanced dust collection systems, which help maintain a clean workspace and ensure compliance with environmental standards. The abrasive recycling system further reduces media consumption and operational costs.

6. Compact Footprint

Crawler shot blasters are generally compact and self-contained, making them ideal for factories with limited space. Their enclosed design also improves safety and reduces noise and dust emissions.

Choosing a crawler shot blaster means investing in a highly efficient, flexible, and cost-effective solution for surface treatment. Its unique tumbling mechanism, robust structure, and batch processing capability make it a valuable tool for improving product quality and production efficiency. Whether you’re working with castings, forgings, or complex metal parts, the crawler shot blaster delivers consistent, professional results every time.

Crawler Shot Blaster – Frequently Asked Questions (FAQ)

A crawler shot blaster is a popular choice for surface cleaning and strengthening of small to medium-sized parts. To help you better understand this machine and its capabilities, here are answers to some of the most frequently asked questions:

1. What is a crawler shot blaster?

A crawler shot blaster is a type of shot blasting machine that uses a rubber or manganese steel crawler belt to tumble parts while blasting them with abrasive media. This process removes rust, scale, sand, or burrs from metal surfaces and can improve surface strength through peening.

2. What types of parts can be cleaned with a crawler shot blaster?

Crawler shot blasters are suitable for cleaning:

- Iron and steel castings

- Heat-treated forgings

- Small to medium-sized automotive parts

- Metal machined components

- Parts with complex shapes or internal cavities

3. How does the crawler belt help in the blasting process?

The crawler belt rotates during blasting, causing the parts to tumble continuously. This exposes all sides of each part to the abrasive stream, ensuring complete and uniform cleaning.

4. What abrasive materials are used in crawler shot blasters?

Common abrasive media include:

- Steel shot

- Steel grit

- Stainless steel shot (for non-ferrous or stainless parts)

The choice depends on the material of the workpieces and the desired surface finish.

5. Is the machine suitable for continuous production?

Crawler shot blasters are typically designed for batch processing rather than continuous operation. However, they are efficient for medium to high production volumes due to their ability to clean multiple parts in one cycle.

6. What are the advantages of using a crawler shot blaster?

- Uniform cleaning and peening

- Handles parts with irregular shapes

- Batch processing saves time and labor

- High durability and easy maintenance

- Compact and enclosed design reduces noise and dust

7. Does it have a dust collection system?

Yes, most crawler shot blasters are equipped with a dedicated dust collector that removes dust and fine particles, keeping the working environment clean and safe.

8. Can the abrasive media be reused?

Yes. The machine has a built-in abrasive recycling system that collects used media, separates debris, and recycles usable abrasive for the next cycle, reducing operating costs.

9. How do I maintain a crawler shot blaster?

Regular maintenance includes:

- Inspecting and replacing worn crawler belts or liners

- Checking the blast wheel and blades for wear

- Cleaning the dust filter system

- Monitoring the abrasive recycling system

Proper maintenance ensures long machine life and stable performance.

10. What industries use crawler shot blasters?

Crawler shot blasters are widely used in:

- Foundries

- Automotive

- Metalworking and machining

- Heat treatment plants

- Forging shops

Crawler shot blasters are reliable, efficient machines for surface preparation of a wide variety of metal parts. Whether you’re new to shot blasting or looking to upgrade your equipment, understanding the basics through this FAQ will help you make an informed decision.

Conclusion

The crawler shot blaster is an essential machine for companies seeking high-quality surface preparation of small to medium metal components. Its tumbling belt system, robust design, and efficient abrasive blasting capability make it a reliable and cost-effective solution for a wide range of industrial applications.