Floor shot blasting machine is a professional surface-preparation device used to clean, roughen, and strengthen floor substrates—mainly concrete and steel surfaces. It works by using a high-speed blast wheel to throw steel shots onto the floor. The impact removes contaminants and creates a uniform surface profile suitable for new coatings or treatments.

In industrial flooring, bridge maintenance, shipbuilding, and road engineering, it is one of the most efficient and environmentally friendly surface-treatment machines.

What Is Floor Shot Blasting Machine?

In many industrial flooring projects, surface preparation is the most critical step.

Floor shot blasting machine is one of the most efficient and stable tools for achieving a clean, roughened, and ready-to-coat surface. Compared with traditional grinding or manual treatment, floor shot blasting provides higher productivity and more consistent results.

What the Machine Does

Floor shot blasting machine uses high-speed blasting turbines to throw steel shots onto the floor surface. The impact removes contaminants such as rust, laitance, old coatings, and weak concrete layers. At the same time, the process creates a uniform surface profile, suitable for epoxy flooring, waterproof coatings, anti-corrosion systems, or road marking works.

The machine automatically recovers steel shots and dust through a closed-loop system, so the operation is cleaner and safer than open blasting.

Working Principle

From an engineer’s perspective, the machine operates through the following steps:

- Turbine Acceleration – The blast wheel rotates at high speed, accelerating steel shots to impact the floor.

- Surface Impact & Removal – The shots break off weak layers and roughen the substrate.

- Shot Recovery – A separator collects reusable shots and filters out broken shots and dust.

- Dust Extraction – A connected dust collector ensures clean, dust-free operation.

This continuous cycle makes the machine highly efficient for large floor areas.

Key Advantages in Workshop Applications

- High Efficiency: Suitable for large square-meter projects such as warehouses, factories, and parking lots.

- Consistent Surface Quality: Achieves uniform roughness, improving coating adhesion.

- Environmental Control: Closed blasting chamber + dust collector reduces dust emissions.

- Low Labor Intensity: One-person operation, stable feed speed, and easy controls.

- Reduced Material Consumption: Proper surface profile reduces coating failure and rework.

Typical Engineering Use Cases

In our workshop we often apply floor shot blasting machines for:

- Concrete surface preparation before epoxy or PU flooring

- Removal of curing agents or weak top layers

- Airport runway and highway marking removal

- Steel plate rust removal before waterproof or anti-corrosion coating

- Oil-storage tank bottom plate rust removal and profile preparation

- Bridge deck maintenance and renovation

- Industrial plant renovation projects

Wherever strong adhesion and stable surface roughness are required, shot blasting is usually the preferred method.

Practical Engineering Tips

Based on daily equipment operation, here are some useful points:

- Control Travel Speed: Too fast → insufficient cleaning; too slow → over-profiling.

- Check Steel Shot Quality: Broken shots reduce impact energy and cleaning uniformity.

- Maintain Seals & Liners: Wear-resistant liners inside the blasting chamber must be inspected regularly.

- Keep Dust Collector in Good Condition: Clogged filters increase dust leakage and reduce visibility.

- Monitor Motor Load: Abnormal vibration or overload usually indicates turbine wear or blockage.

With proper maintenance, a good floor shot blasting machine can operate reliably for many years even under heavy use.

Floor Shot Blasting Machine FAQ

1. How deep does shot blasting remove material?

0.5 mm – 3 mm, depending on:

- Shot size

- Turbine speed

- Machine travel speed

- Concrete strength

2. Does it damage the floor?

No, when operated correctly. Shot blasting removes only weak or contaminated surface layers and produces a uniform profile. Over-blasting may cause excessive roughness, so speed and settings must be controlled.

3. What power source does it use?

Machines are powered by three-phase industrial electricity 220V/380V/400V/440V or customized

4. What maintenance is required?

- Check blast wheel blades and liners for wear

- Replace broken steel shots

- Clean dust collector filters

- Inspect seals and rubber wear parts

- Monitor motor temperature and vibration

- Grease bearings regularly

Good maintenance ensures stable performance and longer machine life.

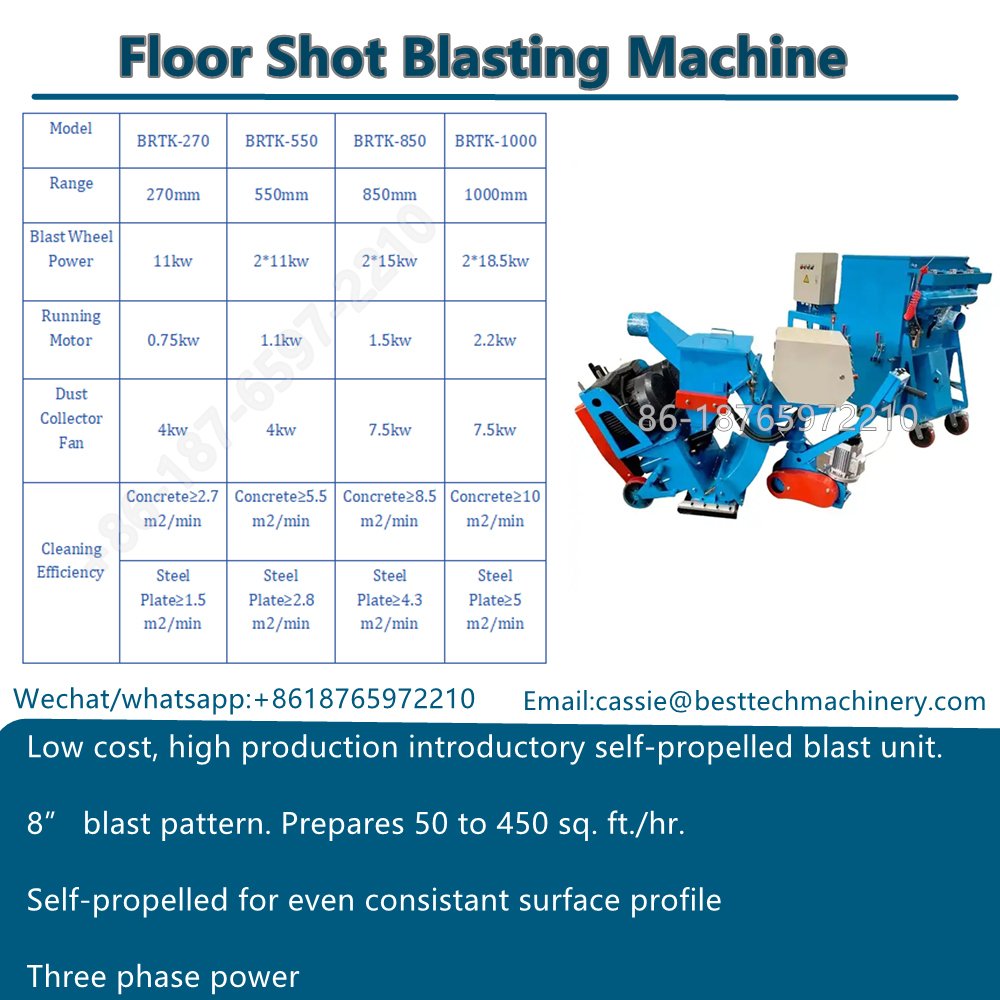

5. How fast can it clean?

Productivity depends on machine model, but typical efficiency is:

- 150–800 m²/h for general concrete floors

- 100–500 m²/h for steel surfaces

6. Can it remove thick epoxy or heavy paint?

It can remove thin or moderately thick coatings. Very thick epoxy or elastic coatings usually require pre-cutting or milling before shot blasting.

7. Is it safe for indoor use?

Yes. With a proper dust collector and good ventilation, indoor operation is common in factories, warehouses, and parking structures.

8. Do steel shots need frequent replacement?

Yes. Steel shots gradually break during operation. A separator removes broken media, and new shots are added regularly to maintain blasting quality.