What Is Tuble Shot Blasting Machine?

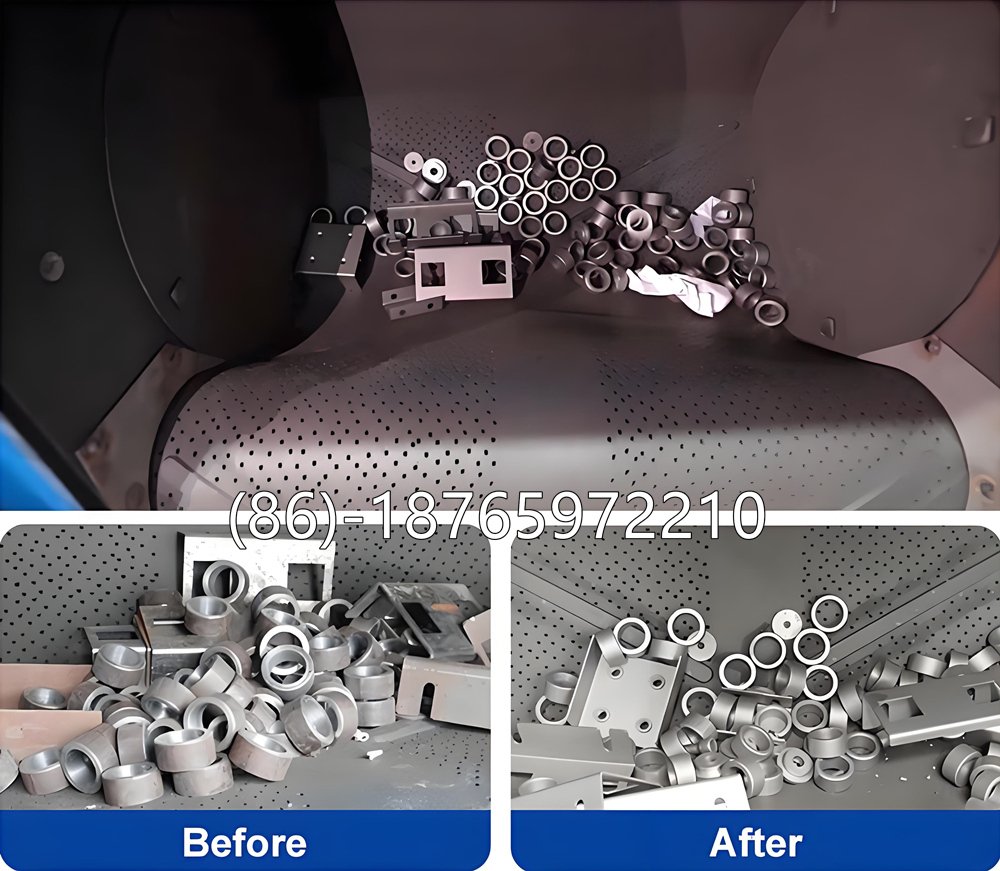

A tumble shot blasting machine is designed for cleaning, descaling, and surface preparation of small and medium-sized workpieces. Parts are loaded in batches inside a rotating drum (either rubber belt or steel flight type). As the drum turns, components tumble over each other while abrasive media is thrown at high speed from the blast wheel. This combination achieves uniform cleaning on all surfaces.

Typical Applications

- Removal of rust, oxide scale, and foundry sand.

- Surface preparation before painting, coating, or galvanizing.

- Deburring of forged or heat-treated parts.

- Increasing fatigue strength by shot peening effect on the surface.

Industries that commonly use tumble machines include foundries, automotive parts, hardware, and machine shops with batch production.

Key Technical Features

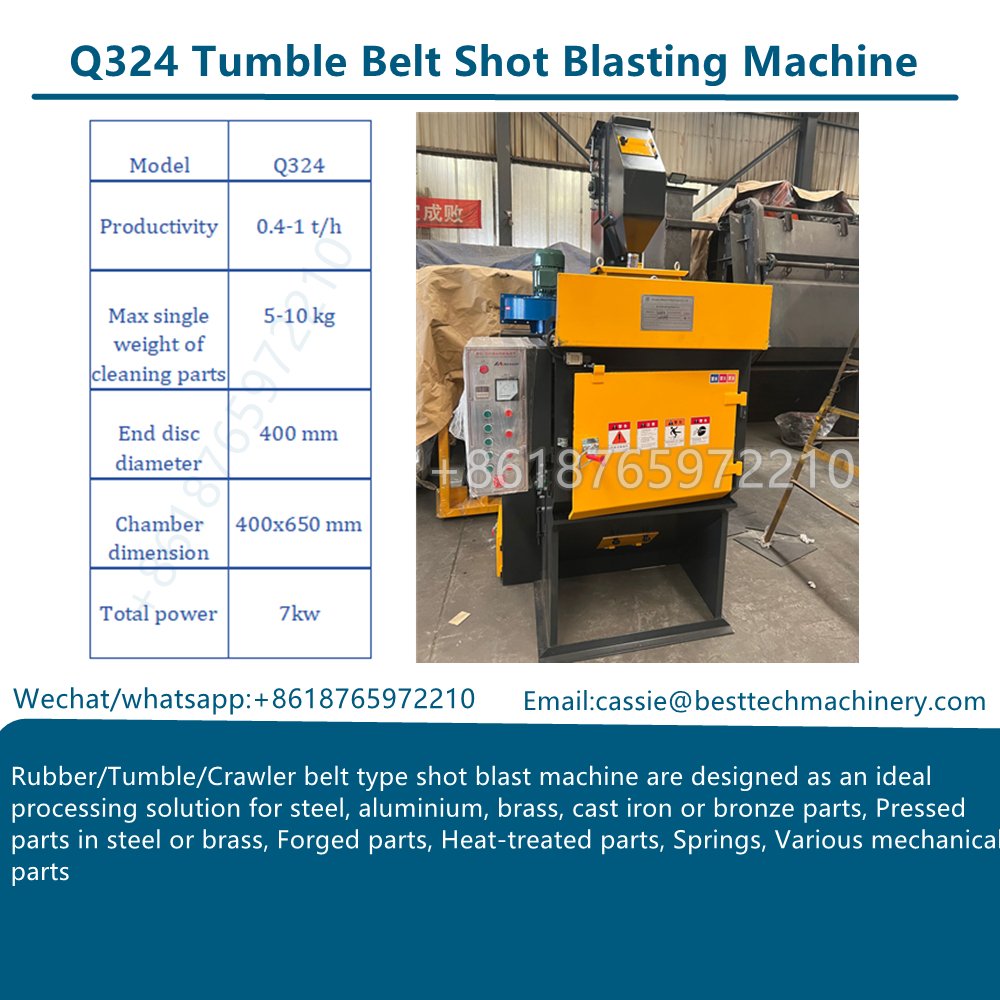

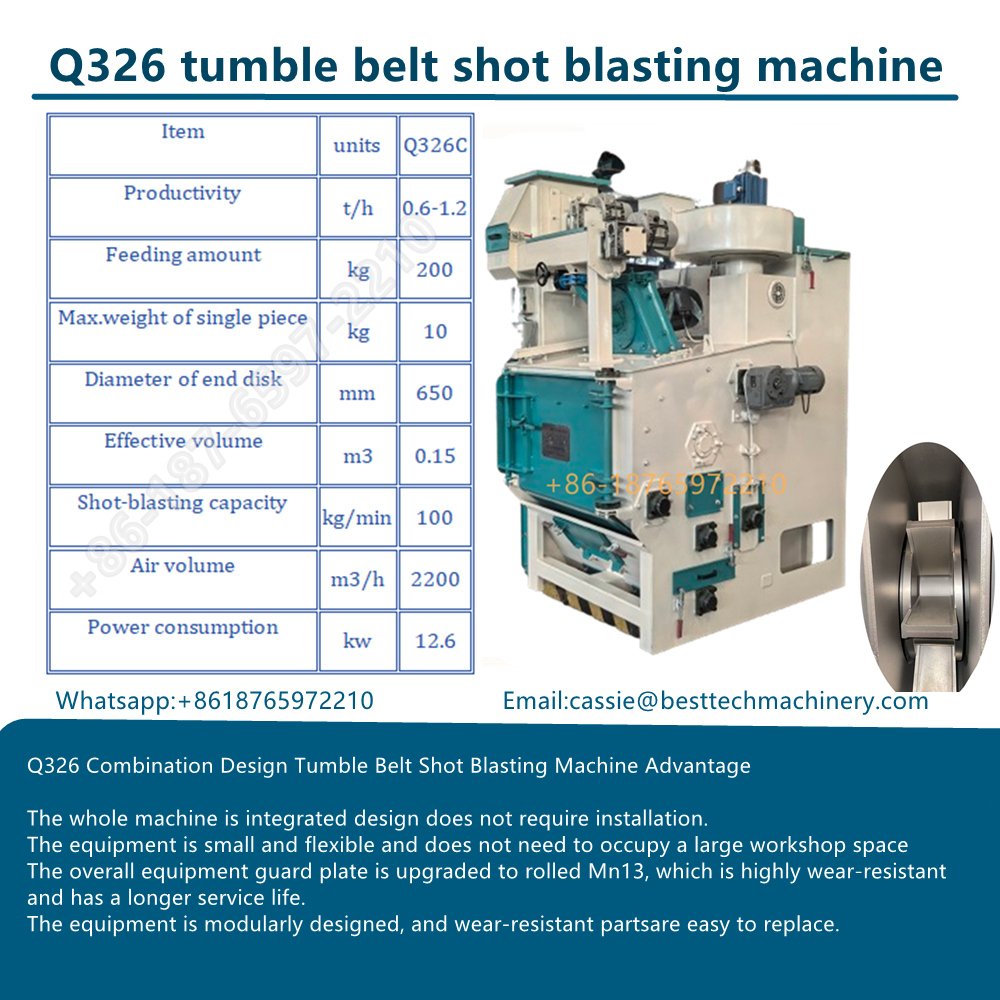

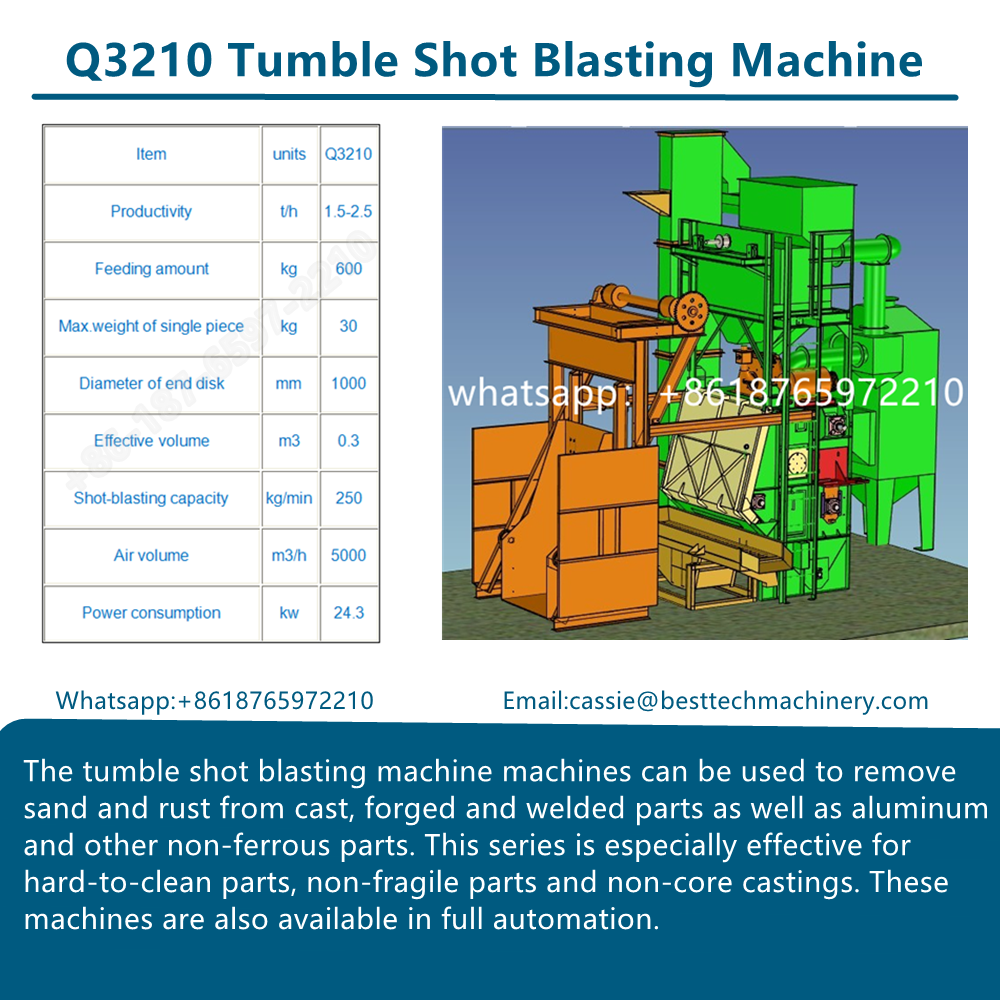

- Batch Capacity: ranges from 100 kg to 1000+ kg depending on model(Q324 with capacity 100kg, Q326 with capacity 200kg, Q3210 with capacity 600kg, Q3220 with capacity 1000kg ).

- Blast Wheel Power: usually 7.5 kW – 22 kW per wheel. Number of wheels varies by machine size.

- Drum Type:

- Rubber Belt: gentle handling, suitable for aluminum or non-ferrous parts.

- Steel Belt: durable, used for cast iron, steel, and heavy-duty parts.

- Abrasive Media: steel shot, steel grit, or stainless shot depending on application.

- Cycle Time: typically 15–30 minutes per batch, adjustable by workpiece condition and required cleanliness.

Operation Notes

- Loading: Do not overload the drum. Overcapacity reduces tumbling action and causes uneven cleaning.

- Abrasive Level: Maintain sufficient abrasive in the storage hopper. Low levels reduce blasting intensity.

- Dust Collection: Always check that the dust collector is working properly. Poor suction will cause abrasive carryover and dusty environment.

- Part Shape: Avoid fragile or very thin parts; they may get damaged during tumbling.

Maintenance Points

- Inspect and replace rubber belt or steel flights regularly.

- Monitor blast wheel blades and liners for wear. Replace in time to avoid imbalance.

- Check seals around drum door to prevent abrasive leakage.

- Maintain proper tension and alignment of drive systems.

- Clean dust filter bags or cartridges frequently.

Advantages

- Efficient cleaning of bulk parts in one cycle.

- Simple structure, relatively low operating cost.

- Uniform cleaning due to continuous tumbling action.

- Can handle a wide variety of part shapes and sizes (within drum limits).

Limitations

- Not suitable for very large, delicate, or flat parts.

- Parts may collide with each other; risk of minor impact marks.

- Limited to batch-type operation, not continuous flow.

How to Choose the Right Tumble Shot Blasting Machine

Selecting the proper tumble shot blasting machine is not just about capacity numbers on a catalog. The right choice depends on your workpieces, production needs, and maintenance resources. Below are the main points engineers usually consider on the shop floor.

1. Workpiece Type and Size

- Material:

- Steel and iron castings → steel belt drum is more durable.

- Aluminum, zinc, or non-ferrous alloys → rubber belt drum prevents damage.

- Size Range: Parts should fit comfortably in the drum. If the largest piece takes up more than 1/3 of drum volume, cleaning will be inefficient.

- Fragility: Very thin or delicate items are not suitable, as tumbling causes impact.

2. Batch Capacity

- Machines are rated in kilograms per batch (e.g. 100, 200, 600, 1000 kg).

- Choose capacity slightly above your average batch weight. Overloading reduces tumbling and underloading wastes energy.

- For mixed production, medium-size machines are more flexible.

3. Cleaning Intensity and Blast Power

- Blast wheels range from 7.5 to 22 kW each.

- Heavy rust, thick scale, or heavy castings require higher kW and sometimes multiple wheels.

- For light burr removal or aluminum parts, lower power is sufficient.

4. Cycle Time and Production Rate

- Typical cycle is 15–30 minutes.

- Calculate daily throughput: (Batch capacity × Number of cycles).

- If you need continuous flow, consider hanger or conveyor-type machines instead of tumble type.

5. Abrasive Media

- Steel shot → general purpose, long life.

- Steel grit → aggressive cleaning, faster scale removal.

- Stainless shot → non-ferrous or stainless workpieces to avoid contamination.

Make sure your machine’s design supports the abrasive type you plan to use.

6. Maintenance and Spare Parts

- Check access for replacing blast wheel blades, liners, and belt/flight sections.

- Simpler designs with standard parts reduce downtime.

- A strong dust collector is essential; undersized systems cause trouble on the shop floor.

7. Safety and Dust Control

- Ensure the machine has proper sealing at the drum door to prevent abrasive leakage.

- Dust collector should keep environment below allowable dust concentration.

- Noise level is also worth checking for operator comfort.

8. Budget vs. Lifetime Cost

- Cheaper machines may save initial investment but wear out faster.

- Consider energy consumption, liner life, and availability of spares.

- A slightly higher upfront cost often reduces total cost per ton of cleaned parts.

Engineer’s Tip

Always bring actual workpieces to the machine supplier for a test blast. Real results are more reliable than catalog data.