Struggling with metal surface treatment effect?

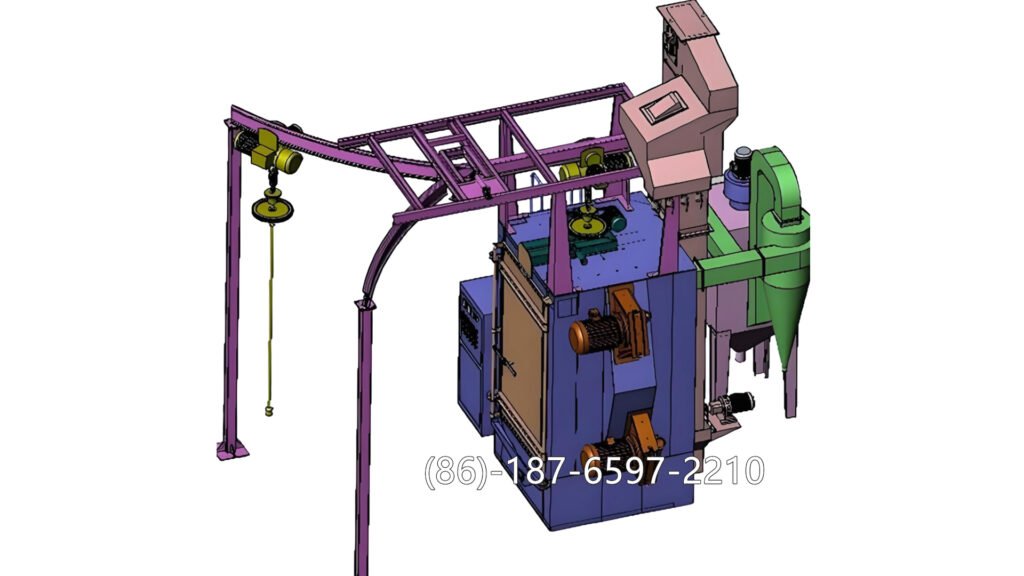

Hanger shot blasting machine is a type of surface treatment equipment used to clean, strengthen, or polish metal workpieces by blasting them with a high-speed stream of abrasive materials (usually steel shot or grit). It’s one of the most common machines in foundries, automotive, construction, and metal fabrication workshops for removing rust, scale, paint, or sand from castings, forgings, and weldments.

Factors Affecting Cleaning Effect & Use Precautions

For years of experience, I’ve learned that getting the best cleaning results from a hanger shot blasting machine depends on a combination of mechanical settings, process control, and regular maintenance. Below are the key factors that affect cleaning performance, along with important precautions for daily operation.

Factors Affecting Cleaning Effect

1. Shot Blasting Wheel Speed and Direction

The speed and angle of the blasting wheel directly determine how effectively the abrasive hits the workpiece surface.

- If the wheel speed is too low, rust and scale may not be completely removed.

- If too high, it may cause over-blasting or unnecessary wear.

- Always adjust the blasting direction to ensure full surface coverage without blind zones.

2. Type and Size of Abrasive

Selecting the right abrasive material and size is essential.

- Steel shot provides strong impact for heavy rust removal.

- Steel grit gives better surface roughness for coating preparation.

- The mixture ratio of different abrasive sizes should be maintained for consistent results.

3. Workpiece Hanging Method

Proper fixture and hanging position affect both cleaning uniformity and efficiency.

- Ensure that the parts can rotate or swing freely to expose all surfaces.

- Overlapping or stacking workpieces can lead to uneven cleaning and wasted energy.

4. Blasting Time and Flow Rate

The blasting duration must be matched with the material and contamination level.

- Too short — incomplete cleaning.

- Too long — excessive wear on both parts and machine.

- Control the abrasive flow rate to balance cleaning effect and consumption.

5. Ventilation and Dust Removal System

A stable dust collector system is crucial for visibility and machine health.

- Clogged filters reduce suction efficiency, causing dust to settle on cleaned surfaces.

- Regular cleaning of filters and ducts ensures stable air pressure inside the chamber.

Precautions for Safe and Efficient Use

1. Pre-check Before Operation

- Inspect the wear condition of blades, liners, and rubber curtains.

- Ensure the door and safety interlocks are functioning properly.

2. Load Properly

- Avoid overloading; excessive weight affects chain drive and motor load.

- Distribute workpieces evenly to maintain balance during rotation.

3. Monitor Operating Parameters

- Keep an eye on the current, blasting wheel speed, and separator performance.

- Irregular sounds or vibration indicate potential mechanical issues.

4. Maintain Abrasive Circulation System

- Check for leaks in screw conveyors and elevator buckets.

- Replace or supplement abrasives when the quantity drops below the standard level.

5. Regular Maintenance and Record Keeping

- Keep dust collector filters clean

- Maintain stable air pressure and visibility

Conclusion

The hanger shot blasting machine is a reliable and powerful tool for surface cleaning — but only when it’s used under controlled conditions and proper maintenance.

By focusing on factors such as wheel speed, abrasive selection, hanging method, and ventilation, we can achieve consistent cleaning results, extend equipment life, and ensure safe, efficient production in the workshop.

FAQ (Frequently Asked Questions)

1. What is a hanger shot blasting machine?

A hanger shot blasting machine is an automatic cleaning system that removes rust, oxide scale, paint, and sand from metal parts by propelling steel shot or grit at high speed. The workpieces are hung on rotating hooks or hangers to ensure all surfaces are evenly cleaned.

2. What kinds of parts can be cleaned?

It’s suitable for castings, forgings, weldments, and structural steel — especially those with irregular shapes or complex surfaces that can’t be tumbled in a drum. Common parts include:

- Engine blocks and housings

- Steel frames and beams

- Gears, springs, and brackets

3. How does the machine work?

- Workpieces are hung on hooks or hangers.

- The door closes, and the hanger rotates.

- High-speed blasting wheels throw abrasives onto the parts.

- Rust and scale are removed, and the clean surface is revealed.

- Abrasive material is automatically collected, cleaned, and reused.

4. What are the advantages of using a hanger type machine?

- Uniform cleaning with full surface coverage

- High efficiency and reduced labor cost

- Compact structure, easy loading/unloading

- Environmentally friendly — equipped with dust collector

- Long service life when maintained properly

5. What types of hanger machines exist?

- Single Hook Type: For small batches or large parts

- Double Hook Type: One hook loads while the other cleans — for continuous operation

- Continuous Conveyor Type: For high-volume production lines

6. What abrasives can be used?

Usually steel shot or steel grit, depending on the desired surface roughness:

- Steel shot → smoother surface, suitable for finishing

- Steel grit → rougher surface, ideal for coating preparation

7. What should operators pay attention to?

- Check wear of blades, liners, and rubber curtains regularly

- Keep dust collector filters clean

- Ensure door interlocks and limit switches function properly

- Avoid overloading and uneven hanging

- Record maintenance and replace worn parts on schedule

8. How to maintain good blasting performance?

- Maintain correct abrasive flow rate and mix ratio

- Adjust blasting wheel angle for even coverage

- Keep abrasive circulation and separator systems clean

- Regularly inspect bearings, chains, and motors

9. What surface finish can be achieved?

Typically Sa 2.5 – Sa 3.0 grade (ISO 8501-1), which means a clean, metallic surface ready for painting, coating, or galvanizing.

10. How often should maintenance be performed?

- Daily: Check blades, seals, and air pressure

- Weekly: Inspect filters, belts, and bearings

- Monthly: Check chamber liners and abrasive circulation system