In the field of industrial surface treatment, the floor shot blaster has become an essential piece of equipment for preparing concrete and steel flooring surfaces. Known for its high efficiency, dust-free operation, and environmental friendliness, this machine plays a critical role in a wide range of applications, from road maintenance to warehouse renovations.

What is a Floor Shot Blaster?

A floor shot blaster is a surface preparation machine that uses high-speed steel shots propelled by a rapidly rotating blast wheel. The shots impact the surface with force, removing contaminants such as old coatings, paint, rust, adhesives, and laitance, while also roughening the surface to improve adhesion for new coatings or overlays.

This process is completely mechanical—no water or chemicals are needed—making it ideal for eco-friendly and dry applications.

Key Benefits of Floor Shot Blasting

- High Efficiency

Floor shot blasters cover large areas quickly, making them ideal for commercial and industrial projects. Some models can treat hundreds of square meters per hour. - Consistent Surface Profile

The shot blasting process creates a uniform surface texture, which is crucial for bonding epoxy, polyurethane, or other coatings. - Dust-Free Operation

Most floor shot blasters come equipped with an integrated dust collector or vacuum system, keeping the worksite clean and safe. - Eco-Friendly

As a dry, chemical-free process, shot blasting is safer for workers and more environmentally responsible compared to acid etching or solvent-based methods.

Common Applications

- Concrete floor preparation before coating or painting

- Steel floor and deck cleaning in shipyards or industrial plants

- Removal of old coatings, lines, adhesives, and contamination

- Anti-slip surface preparation for public walkways or parking garages

- Airport runway and bridge deck resurfacing

How It Works

The floor shot blaster propels steel shots at high velocity onto the floor surface. The rebound and debris are collected and separated; reusable steel shots are recycled back into the system, while dust and waste are filtered and collected. This closed-loop system ensures minimal waste and maximized productivity.

Choosing the Right Floor Shot Blaster

When selecting a floor shot blaster, consider the following:

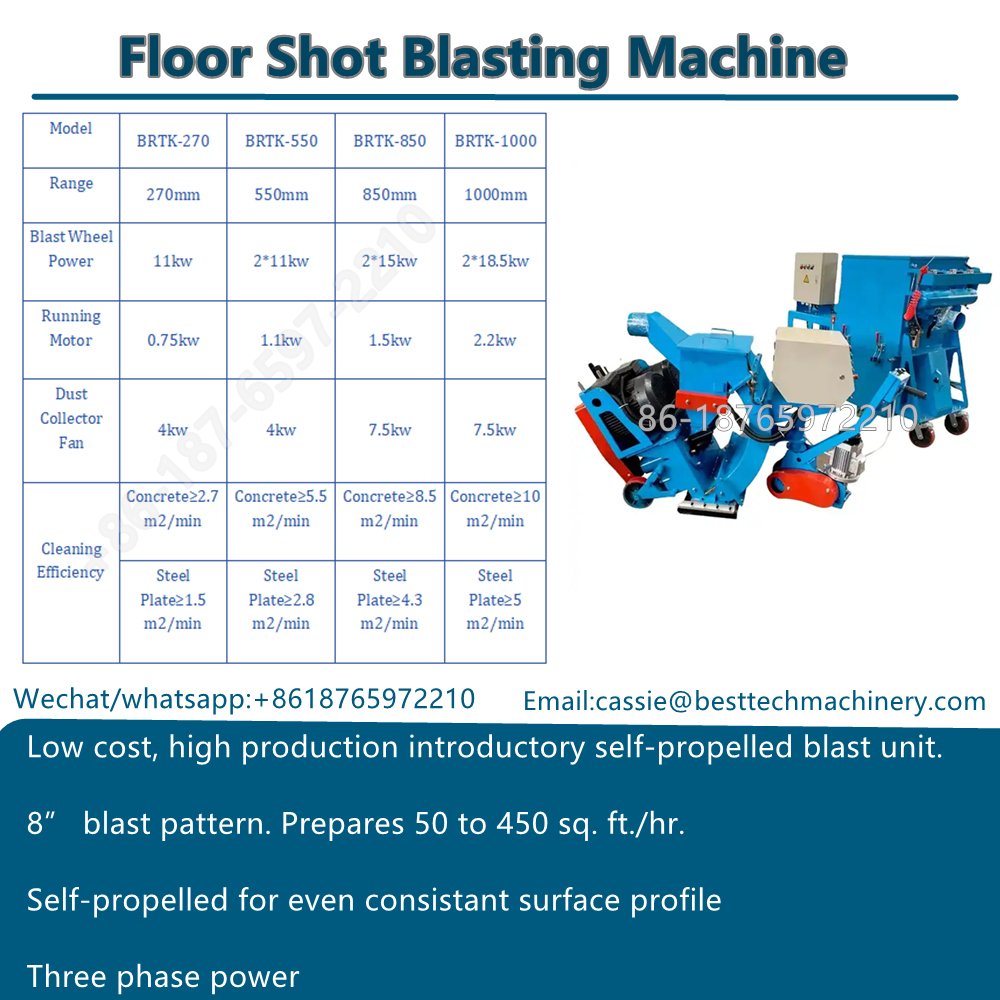

- Working width – Determines how much area the machine can cover in one pass

- Power source – Electric or diesel-powered options are available

- Dust collection system – A strong vacuum system ensures dust-free operation

- Portability – Compact models are ideal for confined spaces or small job sites

How to Choose the Right Floor Shot Blaster?

Choosing the right floor shot blaster is critical for achieving efficient, high-quality surface preparation. Whether you’re preparing concrete floors for coatings, removing rust from steel decks, or cleaning road surfaces, selecting the proper equipment can significantly impact productivity, surface finish, and operational costs. This guide will help you make an informed decision based on your specific application needs.

1. Determine Your Application Type

Start by identifying the primary purpose of the shot blaster:

- Concrete surface preparation (e.g., for epoxy or polyurethane coating)

- Coating or adhesive removal

- Steel deck or bridge cleaning

- Road surface or airport runway treatment

- Anti-slip surface texturing

Each application may require different blasting intensity, machine size, and abrasive type.

2. Assess the Working Width

The working width of the machine affects how much surface area it can treat in a single pass. Consider:

- Small areas or confined spaces: Choose compact models with working widths of 200–300 mm.

- Medium-sized projects: Machines with 400–600 mm widths are ideal for warehouses, garages, or shop floors.

- Large-scale industrial or highway projects: Opt for wider machines (up to 800 mm or more) to maximize efficiency.

3. Consider the Surface Material and Hardness

- Soft surfaces (e.g., concrete): Require less aggressive blasting. Use machines with adjustable blast intensity to avoid damaging the surface.

- Hard surfaces (e.g., steel, stone): Need higher power and durable blast wheels.

- Always check if the machine allows control over blast pressure and speed for optimal surface profiling.

4. Evaluate Dust Collection and Filtration

A built-in or connected dust collector is essential for safe, clean, and compliant operation:

- Look for HEPA-filtered vacuum systems for indoor or sensitive environments.

- Ensure that the machine provides near dust-free performance to meet safety regulations and protect workers.

5. Check Power Requirements

- Electric-powered machines are clean and quiet—suitable for indoor use.

- Diesel-powered machines offer higher mobility and are ideal for outdoor or large-scale road projects.

- Always verify that the power supply at your job site matches the machine’s requirements (e.g., voltage and phase).

6. Mobility and Portability

- Choose self-propelled models for ease of operation and minimal manual effort.

- Consider weight and maneuverability, especially if you need to move the machine up/down stairs or between job sites frequently.

7. Maintenance and Durability

- Opt for machines made with high-strength materials and easy-access designs for quick maintenance.

- Check the availability of spare parts, after-sales support, and training resources from the manufacturer or distributor.

8. Budget and Return on Investment

- Don’t just look at the upfront price—consider long-term costs such as abrasive consumption, energy use, maintenance, and downtime.

- Investing in a reliable, efficient machine can lead to faster project turnaround and higher profitability.

Choosing the right floor shot blaster depends on a careful evaluation of your project scale, surface type, work environment, and operational needs. A well-matched machine not only ensures optimal surface preparation results but also enhances job site safety and project efficiency. Take the time to assess all key factors—and when in doubt, consult with an experienced equipment supplier or manufacturer for tailored recommendations.

Why Choose the Floor Shot Blaster?

In today’s fast-paced industrial and construction environments, efficiency, safety, and surface quality are non-negotiable. Whether you’re preparing concrete floors for coating, removing old layers, or cleaning steel decks, the floor shot blaster has emerged as a top choice for professionals across many industries. But why exactly should you choose a floor shot blaster over other surface preparation methods? Let’s explore.

1. Superior Surface Preparation

The floor shot blaster delivers a clean, textured surface ideal for coatings, overlays, or adhesives. By propelling steel shots at high speed, it removes laitance, rust, paint, and contaminants while creating a rough profile for better bonding. The result is a consistent and high-quality surface finish that meets industry standards.

2. Dust-Free Operation

Most modern floor shot blasters are equipped with integrated dust collection systems. Unlike grinding or sanding, which can generate significant airborne dust, shot blasting keeps the work area clean and safe. This is especially important in enclosed spaces or facilities with strict environmental regulations.

3. Eco-Friendly Process

Shot blasting is a dry, chemical-free method. It eliminates the need for harsh solvents, acids, or detergents, making it safer for both operators and the environment. The steel shots used are recyclable, reducing waste and operating costs.

4. Highly Efficient and Productive

With the ability to cover large floor areas quickly and uniformly, floor shot blasters are extremely efficient. Many models can process hundreds of square meters per hour, reducing labor time and project duration. For contractors, this translates into higher profitability and faster job turnover.

5. Versatility Across Applications

Floor shot blasters can be used on a wide range of surfaces and in various industries, including:

- Concrete floor preparation

- Steel bridge or deck cleaning

- Parking garage maintenance

- Warehouse floor renovation

- Road and airport surface texturing

Their flexibility makes them a go-to tool for surface preparation professionals.

6. Consistent and Repeatable Results

Manual methods such as grinding or chemical stripping can result in uneven surfaces. Floor shot blasters, on the other hand, provide uniform results with every pass. This consistency is crucial when applying coatings or overlays that require a specific surface profile.

7. Reduced Labor and Operator Fatigue

Many models are self-propelled and designed for ergonomic operation, minimizing strain on workers. This leads to better productivity, fewer mistakes, and improved operator safety.

Choosing a floor shot blaster means investing in a solution that’s fast, clean, efficient, and reliable. It enhances surface preparation quality while saving time, reducing environmental impact, and cutting labor costs. Whether you’re handling a small indoor project or a large-scale industrial job, the floor shot blaster stands out as the smart, professional choice.

Conclusion

Whether you are resurfacing a factory floor or preparing a bridge deck, a floor shot blaster offers a fast, clean, and effective solution. Its ability to deliver consistent surface profiles without water or chemicals makes it a go-to choice for professionals in surface preparation industries. As demand grows for higher-quality finishes and safer work environments, the floor shot blaster continues to prove its value as an indispensable tool.