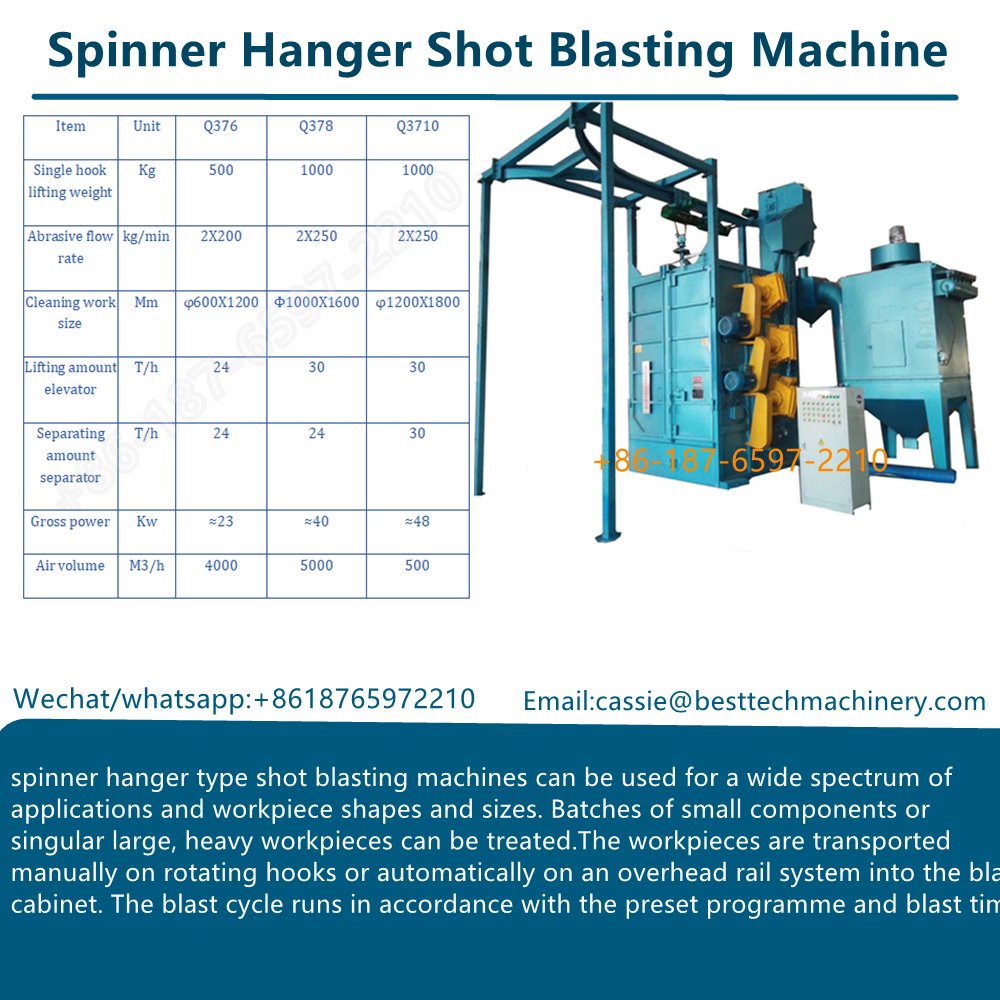

Hanger Shot Blasting Machine Introduction

Hanger shot blasting machines play a crucial role in modern metal surface treatment processes. These specialized machines are designed to clean, strengthen, and prepare metal surfaces for subsequent finishing operations. The hanger-type design allows for efficient processing of various metal components, making it indispensable in industries ranging from automotive to aerospace manufacturing.

Working Principle

The hanger shot blasting machine operates by suspending workpieces on hooks or hangers that rotate as they pass through the blasting chamber. Steel shots or grit are propelled at high velocity onto the metal surfaces, effectively removing scale, rust, paint, and other contaminants. The continuous rotation ensures uniform treatment of all surfaces, including complex geometries.

Key Applications

- Surface Preparation: Removes mill scale, rust, and old coatings prior to painting or coating

- Deburring: Eliminates sharp edges and burrs from machined parts

- Surface Strengthening: Induces compressive stresses to improve fatigue resistance

- Cosmetic Finishing: Creates uniform matte or textured surfaces

- Pre-welding Treatment: Cleans surfaces to ensure proper weld quality

Advantages

- High Efficiency: Can process multiple parts simultaneously

- Uniform Treatment: Rotating hangers ensure consistent coverage

- Versatility: Handles various sizes and shapes of components

- Environmental Benefits: Closed-loop systems minimize media loss and dust emission

- Cost-Effective: Reduces manual labor and processing time

Industry Applications

- Automotive: Engine components, transmission parts, wheels

- Aerospace: Turbine blades, structural components

- Construction: Steel beams, pipes, architectural elements

- Railway: Wheels, axles, bogie components

- General Manufacturing: Castings, forgings, fabricated metal parts

Maintenance Considerations

Proper maintenance is essential for optimal performance:

- Regular inspection of abrasive media

- Monitoring of blast wheel wear

- Proper dust collection system maintenance

- Lubrication of moving parts

- Periodic inspection of hanger mechanisms

Future Trends

Advancements in hanger shot blasting technology include:

- Automated loading/unloading systems

- Intelligent process control systems

- Energy-efficient designs

- Advanced abrasives for specialized applications

- Integration with Industry 4.0 systems

Why Choose Hanger Shot Blasting Machine for Metal Surface Treatment?

1. Superior Surface Preparation Capability

Hanger shot blasting machines excel at preparing metal surfaces for subsequent processes:

- Complete Coverage: The rotating hanger mechanism ensures all surfaces, including complex geometries and internal cavities, receive uniform treatment

- Effective Contaminant Removal: Capable of removing tough mill scale, rust, paint, and oxidation layers that other methods struggle with

- Consistent Surface Profile: Creates ideal anchor patterns for coating adhesion (typically Sa 2.5 to Sa 3 cleanliness standards)

2. Unmatched Process Efficiency

- High Throughput: Multiple parts can be processed simultaneously, significantly reducing cycle times

- Automated Operation: Continuous processing with minimal manual intervention increases productivity

- Quick Changeover: Adaptable to different part sizes and types with simple hanger adjustments

3. Exceptional Quality Control

- Repeatable Results: Programmable parameters ensure identical treatment for every batch

- No Shadow Areas: Rotational movement eliminates untreated spots common in manual blasting

- Controlled Intensity: Precise adjustment of blast pressure and media flow for optimal results

4. Economic Advantages

- Reduced Labor Costs: Automated operation requires fewer operators than manual methods

- Media Conservation: Closed-loop systems recover and reuse up to 99% of abrasive media

- Lower Maintenance: Robust construction with accessible wear parts minimizes downtime

5. Versatility Across Industries

- Material Compatibility: Effective on cast iron, steel, aluminum, and various alloys

- Part Size Range: Accommodates components from small precision parts to large structural elements

- Multiple Applications: Suitable for cleaning, descaling, deburring, peening, and cosmetic finishing

6. Environmental and Safety Benefits

- Contained Process: Fully enclosed operation prevents media and dust escape

- Dust Collection: Integrated systems capture airborne particles for cleaner work environments

- No Chemical Waste: Eliminates hazardous chemical disposal associated with alternative methods

7. Technological Advancements

Modern hanger shot blasting machines incorporate:

- Smart Controls: Automated parameter adjustment and process monitoring

- Energy Recovery Systems: Reduced power consumption

- Predictive Maintenance: Sensors to anticipate service needs before failures occur

Comparative Advantages Over Alternative Methods

FeatureHanger Shot BlastingManual BlastingChemical TreatmentConsistencyExcellentVariableGoodThroughputHighLowMediumOperating CostLowHighMediumEnvironmental ImpactLowMediumHighSurface Finish ControlPreciseOperator-dependentLimited

The hanger shot blasting machine represents the optimal solution for industrial metal surface treatment, combining technical superiority with economic and environmental benefits. Its ability to deliver consistent, high-quality results at scale makes it the preferred choice for manufacturers across multiple industries seeking reliable surface preparation solutions.

Conclusion

Hanger shot blasting machines represent a critical technology in metal surface treatment, offering efficient, consistent, and cost-effective solutions for various industrial applications. Their ability to handle diverse components while delivering high-quality surface preparation makes them invaluable in modern manufacturing processes.