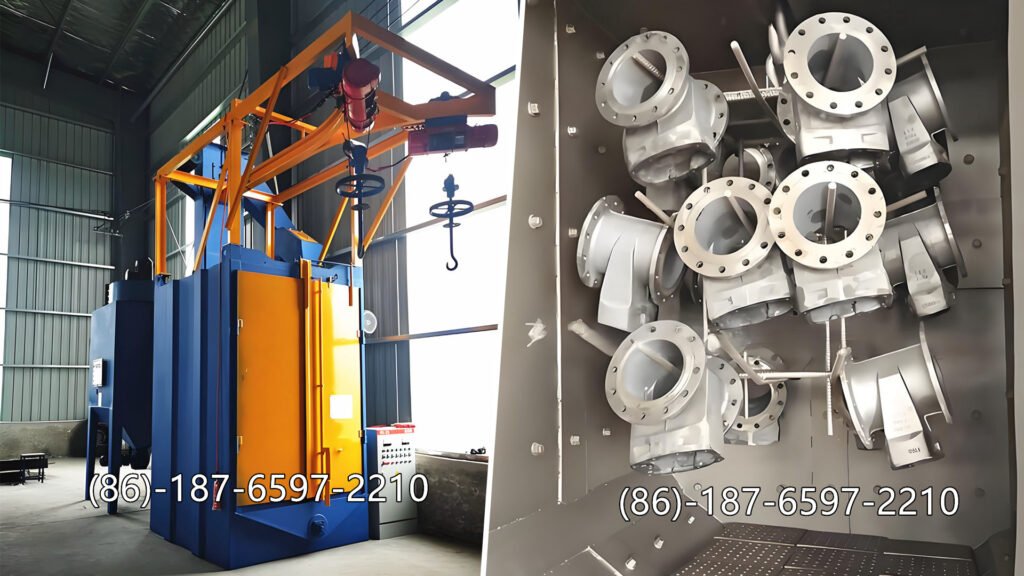

Hanger shot blasting machine is a type of surface cleaning equipment used to remove rust, scale, sand, paint, or other contaminants from metal parts. It is commonly used in foundries, automotive plants, metal fabrication workshops, and machinery manufacturing.

Hanger Shot Blasting Machine Provides The Flexibility And Performance Needed To Meet The Diverse Rust Removal Requirements

In workshop often handle castings, forgings, and welded structures of all shapes and sizes. One common challenge we face is removing rust, scale, and old coatings efficiently without damaging the workpiece. Over time, we have found that the Hanger Shot Blasting Machine provides the flexibility and performance needed to meet the diverse rust removal requirements of different customers.

1. Flexible Loading for Various Workpieces

The hanger design allows us to load components of different weights, dimensions, and geometries. Whether it’s small batch parts, heavy castings, or complex welded structures, the machine can handle them by adjusting the hanger speed and blasting time. This makes it suitable for a wide range of industries — from foundries and automotive parts to machinery fabrication.

2. Efficient Rust and Scale Removal

Equipped with high-power blast wheels and optimized shot flow design, the machine delivers strong and even abrasive impact. This ensures thorough removal of rust, oxide layers, and surface contaminants. After blasting, the metal surface reaches a clean, roughened finish that is ideal for painting, coating, or further processing.

3. Consistent Surface Quality

One advantage of the hanger system is that the workpieces rotate continuously during blasting. This guarantees that all surfaces, including hidden areas, receive uniform exposure. We can achieve consistent Sa2.5–Sa3 cleaning grades across every job, meeting strict customer specifications for surface preparation.

4. Adaptable Process Parameters

Different materials and surface conditions require different blasting intensities. The Hanger Shot Blasting Machine allows easy adjustment of shot flow rate, blast duration, and hanger rotation speed. For example, mild rust can be cleaned quickly with lower shot volume, while heavily corroded steel needs longer blasting with higher intensity. This adaptability saves energy and shot media while maintaining quality.

5. Reliable Performance and Low Maintenance

The machine structure is robust, with wear-resistant liners and easy-to-maintain components. Regular inspection and proper lubrication ensure stable performance over long operation periods. In our daily work, downtime is minimal, and the cost per job remains competitive.

6. Meeting Diverse Customer Needs

Our customers often have different finishing requirements — from light surface cleaning before painting to deep descaling of heavy machinery components. The hanger shot blasting machine can be configured to meet each of these needs precisely, making it a versatile and cost-effective solution for workshops like ours.

Conclusion

In modern production, surface preparation quality directly affects coating adhesion, corrosion resistance, and product lifespan. The Hanger Shot Blasting Machine gives us the flexibility to serve different customers efficiently, regardless of workpiece size or surface condition. It is truly a key piece of equipment in ensuring clean, high-quality metal surfaces across all our projects.