The hanger shot blasting machine is a highly efficient and versatile surface treatment solution widely used in the foundry, automotive, aerospace, and metalworking industries. Designed specifically for cleaning, descaling, deburring, and preparing the surfaces of a wide variety of metal components, the hanger shot blasting machine is ideal for workpieces with complex geometries, delicate surfaces, or heavy parts that cannot be tumbled.

What Is a Hanger Shot Blasting Machine?

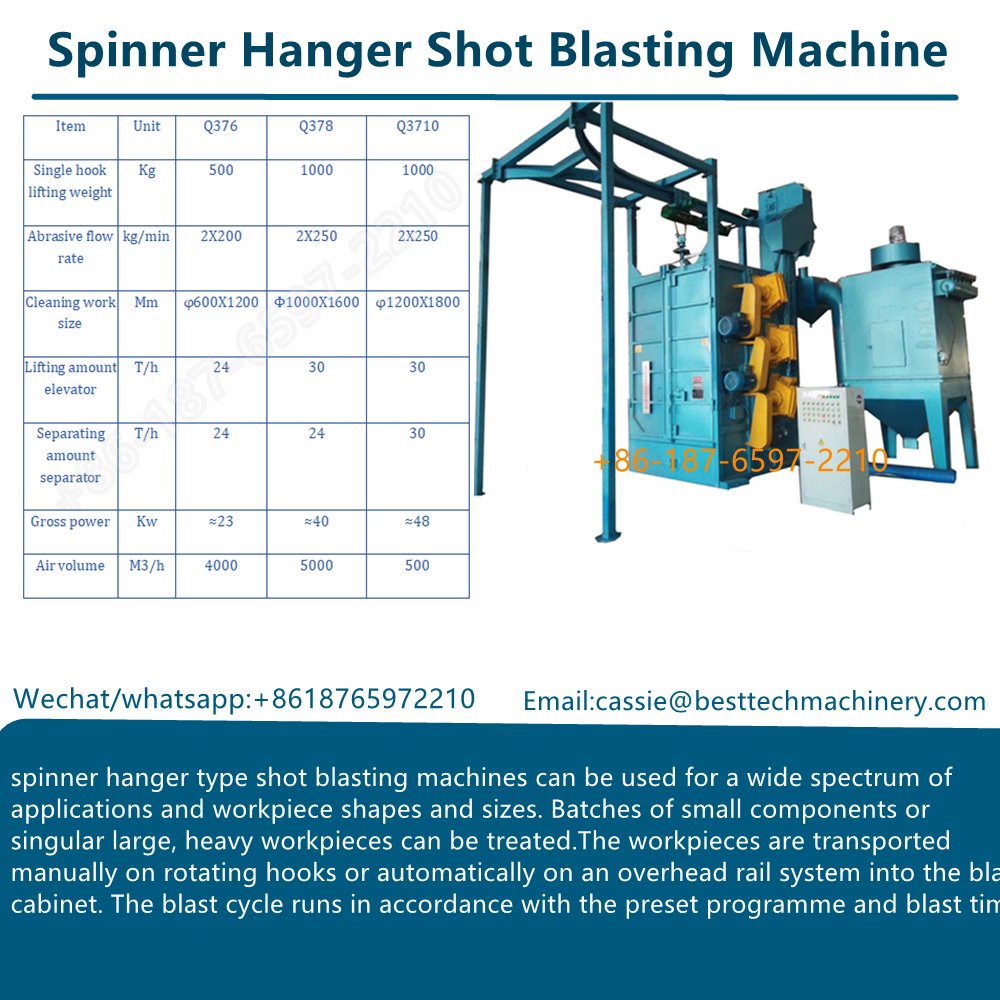

A hanger shot blasting machine is a type of airless blasting equipment where workpieces are hung on a rotating hook (or hanger) and blasted with high-speed abrasive media propelled by a centrifugal blast wheel. The machine typically features one or more hooks mounted on a rotating Y-track or overhead monorail system, allowing continuous or batch-type operation.

As the blasting cycle begins, the hook rotates to ensure uniform exposure of the part to the abrasive stream, resulting in thorough and consistent cleaning.

Key Features:

- Non-Tumbling Operation: Suitable for parts that cannot withstand the impact of tumbling.

- Efficient Rotation: Hooks rotate during blasting to achieve uniform surface coverage.

- High Production Capacity: Dual-chamber or continuous-type designs are available for improved throughput.

- Customizable Hook Systems: Adaptable for parts of various sizes and weights.

Applications:

- Cleaning of castings and forgings

- Paint and rust removal

- Surface preparation before coating or painting

- Shot peening for stress relief

- Descaling of heat-treated parts

Advantages of Hanger Shot Blasting Machines:

- Gentle Handling

The suspended design allows for the safe processing of fragile or intricately shaped components without damage. - Uniform Cleaning

Rotating hooks and strategic blast wheel positioning ensure even abrasive coverage. - Flexible Loading Options

Can accommodate single or multiple parts per hook, depending on size and shape. - Closed Loop System

Abrasive media is collected, cleaned, and reused, reducing operational costs. - Minimal Maintenance

Robust design with wear-resistant components ensures long service life and easy maintenance.

Why Choose a Hanger Shot Blasting Machine? Key Advantages for Industrial Surface Preparation

In the realm of industrial cleaning and surface treatment, hanger shot blasting machines stand out as a premier solution for demanding applications. While alternatives like tumblast, table blast, or conveyor systems exist, hanger-type machines offer unique advantages that make them the optimal choice for specific part profiles and production requirements. Here’s why industries consistently choose this technology:

1. Unmatched Coverage for Complex Geometries

- 360° Processing: Parts suspended on hooks rotate continuously during blasting, ensuring every surface (including recesses, cavities, and internal channels) receives uniform impact.

- No Blind Spots: Unlike flat-table or conveyor systems, hanging orientation eliminates shadow areas caused by part-on-part contact.

- Ideal For: Engine blocks, transmission housings, turbine blades, valve bodies, and structural frames with intricate designs.

2. Gentle Yet Effective Part Handling

- Zero Tumbling: Eliminates part-on-part impact damage common in barrel/tumblast machines.

- Controlled Suspension: Heavy or delicate items (e.g., aerospace castings, large weldments) remain securely fixed, preventing deformation.

- Minimal Fixturing: Custom hooks or fixtures are simple and cost-effective compared to complex conveyor jigs.

3. High Throughput & Batch Flexibility

- Large-Batch Processing: Handle multiple parts simultaneously (typical capacity: 500–5,000 kg per batch).

- Short Cycle Times: Automated loading/unloading reduces idle time (processing cycles typically 5–20 mins).

- Mixed-Processing Capability: Run different parts in the same batch without reprogramming (unlike robotic cells).

4. Superior Process Control & Repeatability

- Precise Parameter Control: Adjust blast time, wheel speed, abrasive flow, and hook rotation for consistent results.

- Automated Operations: PLC systems ensure repeatability across batches, critical for quality-sensitive industries like automotive or aerospace.

- Real-Time Monitoring: Integration with sensors for abrasive flow, dust levels, and wheel RPM.

5. Reduced Operational Costs

- Low Abrasive Consumption: Advanced recovery systems (95%+ reclaim efficiency) minimize abrasive loss.

- Labor Efficiency: 1–2 operators can manage loading/unloading while the system runs autonomously.

- Lower Maintenance: Fewer moving parts than conveyor systems; easy access to wear components like blast wheels or liners.

6. Enhanced Safety & Environmental Compliance

- Fully Enclosed Chamber: Contains noise (<85 dB) and contains abrasive media.

- Integrated Dust Collection: High-efficiency filters capture 99.9% of particulates, meeting OSHA/EPA standards.

- Worker Safety: Operators are shielded from direct exposure to blasting operations.

7. Versatility Across Industries & Applications

- Removes: Scale, rust, sand, oxides, weld slag, and old coatings.

- Prepares Surfaces: For painting, galvanizing, bonding, or NDT inspections.

- Induces Compressive Stress: Improves fatigue life in critical components.

- Industries Served: Foundries, forging, automotive, aerospace, rail, energy, and heavy machinery.

Ideal Use Cases:

- Large, Heavy Parts: Castings, forgings, gears, and fabrications >20 kg.

- Complex Components: Parts with internal passages, threads, or deep recesses.

- High-Value/Delicate Items: Where surface integrity is critical (e.g., investment castings).

- High-Mix Production: Facilities processing varied part sizes/shapes.

Technical Comparison vs. Alternatives:

| Factor | Hanger Type | Tumble Blast | Table Blast |

|---|---|---|---|

| Part Complexity Handling | Excellent | Poor | Moderate |

| Fragile Part Suitability | High | Very Low | Medium |

| Throughput (Large Parts) | High | Low | Medium |

| Abrasive Consumption | Low | High | Medium |

| Footprint | Large | Compact | Moderate |

Conclusion

Hanger shot blasting machines deliver unparalleled versatility, quality, and efficiency for medium-to-large batch processing of complex components. By combining complete surface coverage with gentle handling and automated operations, they reduce rework, lower lifetime costs, and ensure consistent results – making them the investment of choice for industries prioritizing precision surface preparation.