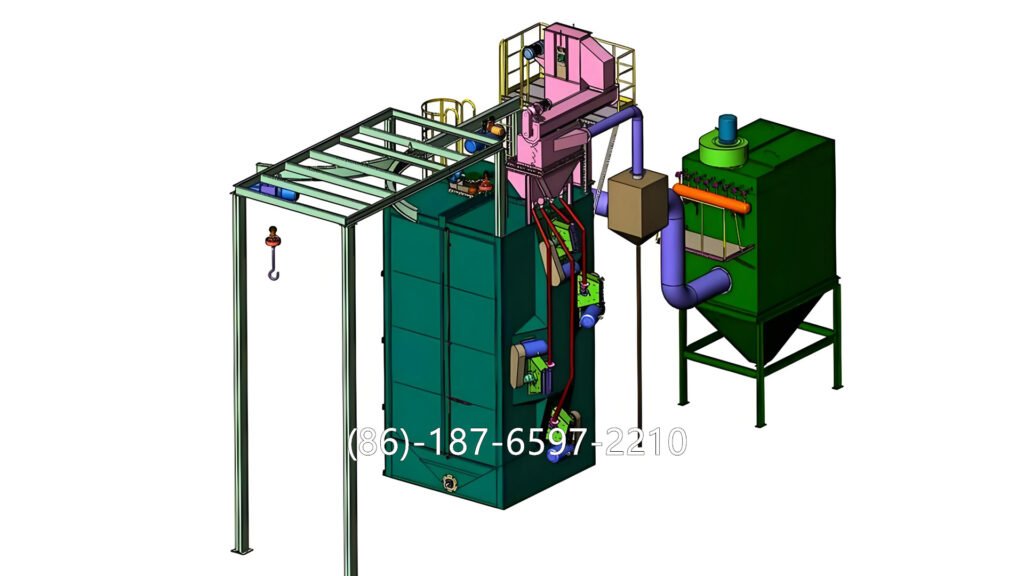

Hanger shot blasting machine is an industrial surface cleaning and finishing equipment designed to remove rust, scale, sand, paint, or other contaminants from metal parts — especially those with complex shapes or delicate surfaces that cannot be tumbled.

Suggestions For Detailing And Optimizing The Use Of Hanger Shot Blasting Machines

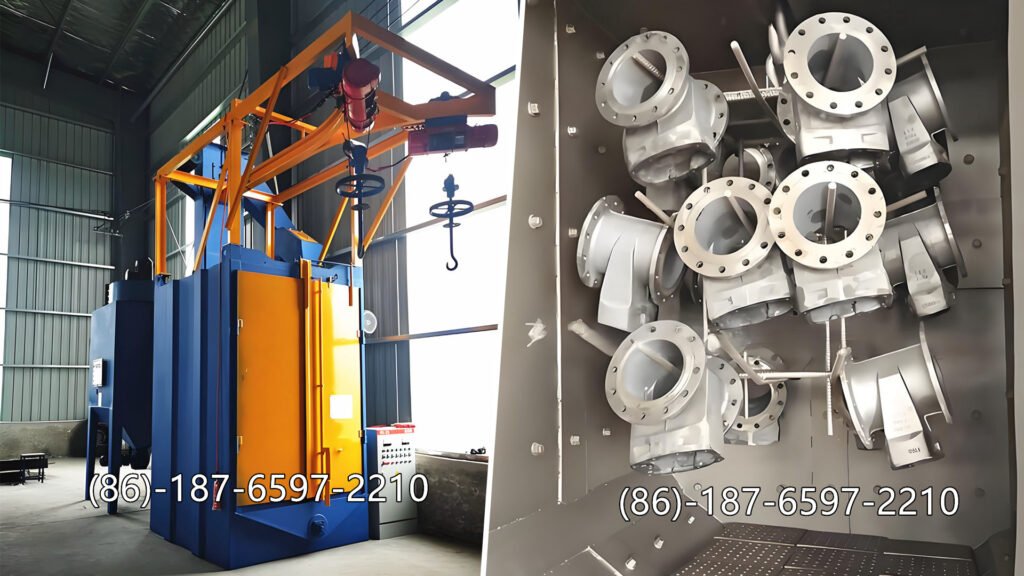

Hanger shot blasting machine is a type of shot blasting system where workpieces are hung on a rotating hanger or hook and blasted with high-speed steel shots propelled by powerful blast wheels. The parts are cleaned uniformly as the hanger rotates inside a sealed blasting chamber.

In our daily production work, the hanger shot blasting machine plays an important role in ensuring consistent surface quality and improving process efficiency. Based on years of operation experience, I would like to share several professional suggestions for detailing and optimizing the use of hanger shot blasting machines in industrial workshops.

1. Understanding the Machine’s Function

The hanger shot blasting machine is mainly used for cleaning and surface strengthening of castings, forgings, and welded components. By using high-speed steel shots, the equipment removes rust, oxide scale, and residues, preparing the surface for painting, coating, or further processing. Its hanging system allows complex or delicate workpieces to be cleaned without collision or deformation.

2. Proper Loading and Arrangement

Before blasting, each workpiece should be hung securely and spaced properly. Avoid overlapping or contact between parts, as this can lead to uneven cleaning and shadow areas. For large or irregular workpieces, adjust the hanger height and rotation speed to achieve full surface coverage during blasting.

3. Setting Correct Blasting Parameters

Different materials and surface requirements demand appropriate adjustments:

- Shot Flow Rate: Maintain the optimal abrasive flow to balance cleaning efficiency and surface roughness.

- Blast Wheel Speed: Higher speed improves cleaning intensity but may cause over-blasting if excessive.

- Blasting Time: Control the cycle duration to avoid unnecessary wear on both the part and equipment.

Continuous monitoring of these parameters ensures uniform surface quality and prolongs machine life.

4. Regular Inspection and Maintenance

Stable operation depends on good maintenance discipline:

- Check blast wheel blades, liners, and control cages regularly for wear.

- Ensure the separator functions well to remove dust and broken media from the abrasive mix.

- Clean the dust collector filters frequently to maintain airflow and prevent dust accumulation.

- Inspect the hanger chain and rotation mechanism to avoid vibration or misalignment.

These preventive measures can significantly reduce downtime and repair costs.

5. Safety and Operational Practices

Operators must always follow safety protocols:

- Wear protective clothing, gloves, and face shields during operation.

- Confirm that all doors and safety interlocks are closed before starting the blasting cycle.

- Never enter the blasting chamber during operation.

- Conduct periodic safety checks on emergency stop switches and control systems.

Safety is not only a rule but also the foundation of stable production.

6. Improving Productivity

To maximize efficiency:

- Use double-door or twin-hanger models to load the next batch while the current one is being blasted.

- Implement automatic shot recycling and dust collection systems to minimize manual handling.

- Schedule maintenance during shift changes or idle hours to reduce production interruptions.

Such improvements lead to smoother workflow and consistent production rhythm.

7. Environmental and Cost Benefits

Modern hanger shot blasting machines are designed for energy efficiency and media recycling. By maintaining a clean abrasive circulation system and using high-efficiency dust collectors, workshops can reduce waste generation and lower energy consumption—meeting environmental standards while cutting operational costs.

Conclusion

A well-maintained hanger shot blasting machine not only enhances surface quality but also reflects the workshop’s overall management level. Through careful loading, correct parameter control, regular maintenance, and safe operation, we can fully utilize the equipment’s performance and achieve long-term, stable production results.