Horizontal Parting Cold Box Core Shooting Machine is a specialized piece of industrial equipment used in the casting industry for producing cores. Cores are an essential component in sand casting, as they create hollow sections or intricate internal shapes within the casting.

Features and Functions:

Cold Box Technology:

Utilizes chemically bonded sand for core production.

Curing is done at room temperature using a gas catalyst (commonly amine-based).

High precision and strength cores are produced.

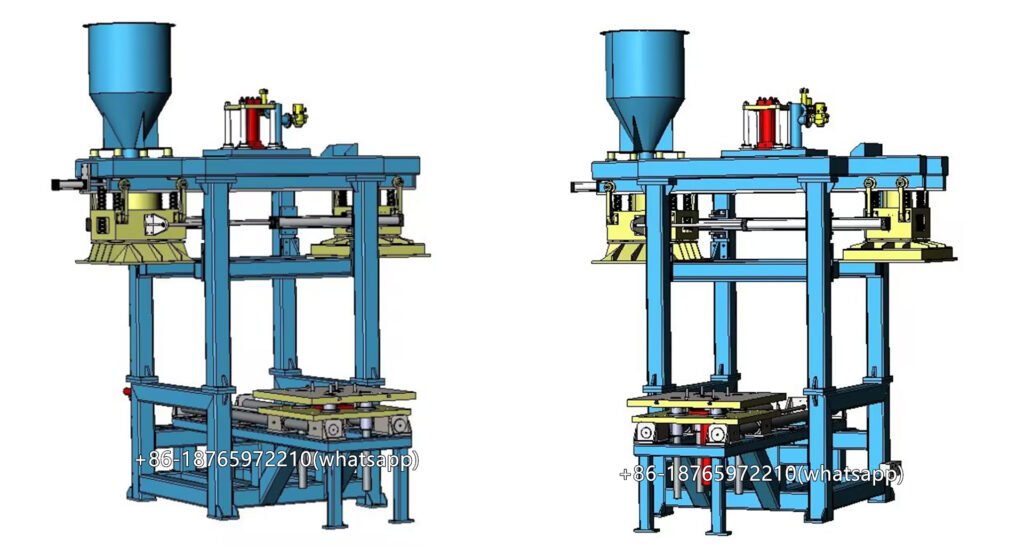

Horizontal Parting Design:

The machine operates with a horizontal parting line, where the core box is split horizontally.

This design allows for easier handling of large or complex core boxes.

It provides uniform filling of sand, ensuring consistent core density.

Core Shooting Mechanism:

The machine shoots sand into the core box under high pressure.

A combination of air compression and vibration ensures the sand is tightly packed.

Automation Features:

Automated sand mixing, core shooting, and gas purging.

PLC (Programmable Logic Controller) systems for precise operation and control.

Some machines may integrate robotic handling systems for increased efficiency.

Advantages:

Fast cycle times and high production rates.

Excellent dimensional accuracy and surface finish.

Reduced labor requirements due to automation.

Environmentally friendly compared to traditional hot box methods.

How Horizontal Parting Cold Box Core Shooting Machine Works?

- Core Box Preparation

The core box (a mold used to shape the sand core) is mounted on the machine. It consists of two parts that split horizontally.

The box is coated with a release agent to ensure easy removal of the core after curing.

The core box is clamped securely in place. - Sand Preparation

Sand is mixed with a resin binder and a catalyst in a sand mixer attached to the machine.

The sand mixture is kept consistent and uniform for optimal strength and shape. - Core Shooting

The mixed sand is loaded into the sand hopper of the machine.

The machine uses compressed air to “shoot” or inject the sand into the core box at high speed and pressure.

The shooting process ensures the sand fills every cavity in the core box, forming the desired shape. - Curing (Gas Purging)

Once the sand is packed, a gaseous catalyst (commonly amine gas) is introduced into the core box.

The gas reacts with the resin binder in the sand, causing it to harden (cure) instantly at room temperature.

This results in a strong and durable core. - Core Removal

After curing, the core box opens along its horizontal parting line.

The hardened sand core is ejected automatically or manually.

The core is inspected for defects and stored for use in the casting process. - Cleaning and Repeating the Cycle

The core box is cleaned, and the release agent is reapplied if necessary.

The machine is prepared for the next cycle.

Applications:

Automotive: For producing engine blocks, cylinder heads, and other complex components.

Aerospace: Manufacturing lightweight but durable components with intricate designs.

Industrial Equipment: Producing parts for pumps, compressors, and heavy machinery.

Conclusion

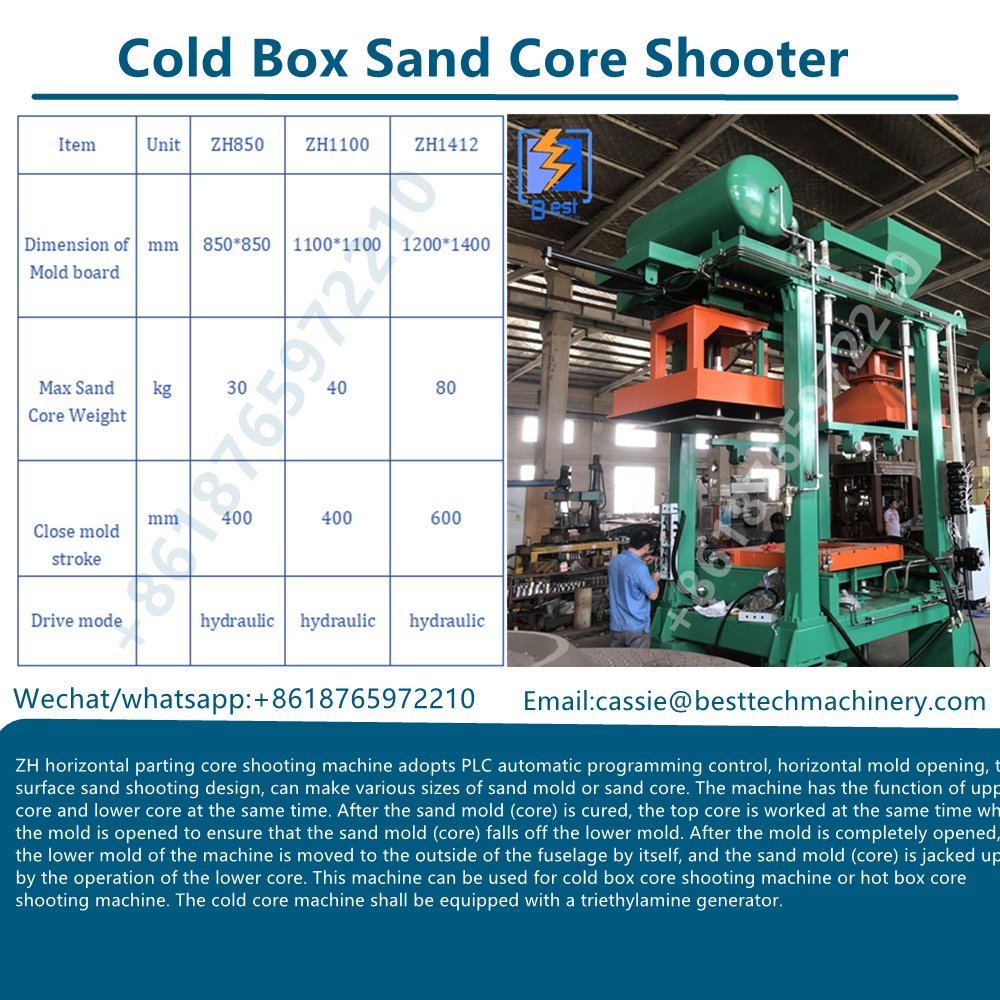

Cold Box Core Shooting Machine, also called cold box core shooter, refers to adopting a core box at normal temperature and using amine(TEA, DMA, etc.) as a catalyst to cure the phenolic resin-coated sand.