Shot blasting machine is basic equipment in modern metal processing. Main function is to remove rust, oxide skin, and sand, also to make surface rough for better coating or welding. In some cases, blasting can improve fatigue strength of parts.

Different machine type has different advantage: for example, tumble type is suitable for small bulk parts, roller conveyor type is used for plates and profiles, while hanger type is better for large or complex shape workpieces. By selecting proper machine and adjusting process parameters such as shot flow rate, blasting time, and wheel speed, stable surface quality can be achieved.

In practice, effect of blasting not only depend on machine, but also on abrasive type, maintenance condition, and operator experience. Good operation can reduce cleaning time, lower abrasive consumption, and improve part quality.Technical Notes on Shot Blasting Machines

Role in Metal Processing

Shot blasting machines are standard equipment in foundries, fabrication shops, and steel plants. Their primary function is to remove rust, oxide scale, and molding sand. In addition, blasting creates a controlled rough surface that improves coating adhesion and welding quality. For some load-bearing parts, it also contributes to higher fatigue strength by introducing compressive stress on the surface.

From practical experience, blasting quality is not determined by the machine alone. Abrasive type, separator efficiency, wheel condition, and operator settings all influence the result. A well-maintained machine with stable parameters will not only improve part quality but also reduce abrasive consumption and downtime.

Machine Types and Typical Applications

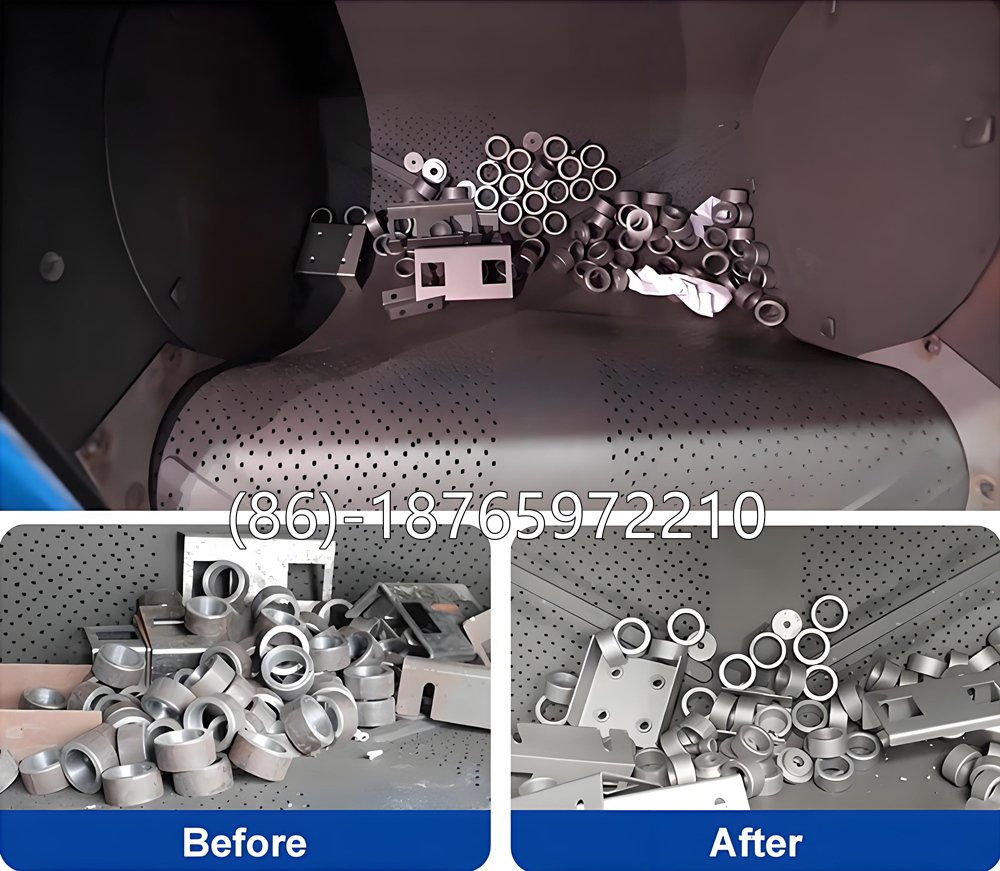

- Tumble Type

Best suited for small to medium bulk parts such as castings and hardware. Typical batch load: 200–800 kg. Cleaning efficiency is high, but fragile or sharp-edged parts may suffer damage from collisions. - Hanger Type

Designed for large, heavy, or complex components (100 kg up to several tons). Each workpiece hangs freely, so there is no part-to-part collision. Cleaning coverage depends on hanger rotation and wheel positioning. - Roller Conveyor

Mainly used for steel plates, beams, and profiles (600–4500 mm wide). Often integrated into production lines. Advantage: continuous processing. Limitation: requires significant floor space. - Turntable Type

Used for irregular-shaped or medium-sized workpieces. Workpieces are fixed on a rotary table (Ø1.2–3 m). Offers good flexibility but limited throughput. - Steel Belt Tumble

Suitable for aluminum and thin-walled parts. The flexible steel belt reduces collision damage compared with traditional tumblers, but load capacity is lower.

Surface Quality Standards

According to ISO 8501:

- Sa2.5: Surface free of oil, scale, and rust; only slight shadows permitted.

- Sa3: White metal finish, completely uniform metallic appearance.

In practice, Sa2.5 is the most common standard in shipbuilding and steel structures, while Sa3 is required for high-performance coatings or critical components.

Key Parameters and Selection

- Abrasive size: Common range 0.8–1.5 mm. Smaller shots improve surface coverage and are safer for thin parts; larger shots remove heavy scale faster.

- Abrasive hardness: Typically 40–65 HRC. Softer abrasives reduce wear on the wheel and are suitable for aluminum; harder abrasives cut faster but generate more dust.

- Wheel speed and shot flow: Must be matched. High wheel speed without proper shot flow leads to wasted energy and poor coverage.

- Loading: Overloading a tumbler or table reduces blasting efficiency and causes uneven cleaning.

Application Examples

- Foundry: Removal of sand and scale from iron and steel castings. Essential before machining.

- Steel Plates / Shipyards: Pre-cleaning of plates and profiles to improve welding and coating.

- Automotive: Cleaning and peening of suspension arms, gears, and chassis components to extend fatigue life.

- Aerospace: Controlled blasting on fasteners, brackets, and turbine blades, mainly to improve fatigue strength.

- Construction Maintenance: Removing old paint and rust from bridges and pipelines for recoating.

Operational Notes

- Always perform trial runs on thin-walled parts before full production.

- Keep the separator and dust collector clean; otherwise, contaminated shots reduce efficiency.

- Regularly inspect wheel blades and liners. Worn blades reduce throwing speed by up to 20%, directly affecting cleaning quality.

- Monitor current load on blast wheels. Unusual spikes often indicate bearing wear or material blockage.

Common Problems and Remedies

| Problem | Likely Cause | Remedy |

|---|---|---|

| Poor cleaning | Insufficient shot flow / worn blades / dirty separator | Adjust flow; replace blades; clean separator |

| Uneven blasting | Wrong wheel angle / workpiece not rotating properly | Re-adjust impeller angle; check hanger or conveyor drive |

| Excessive vibration | Rotor imbalance / liners worn unevenly | Balance rotor; replace liners |

| High shot consumption | Shot too brittle / airflow too strong | Use 40–55 HRC shot; adjust separator airflow |

| Dust leakage | Filter clogged / fan weak / pipe leakage | Replace filters; check fan; repair leaks |

| Workpiece dents | Shot too large / cycle too long | Switch to smaller shot; reduce cycle or wheel speed |

Engineer’s Conclusion

Shot blasting is not just about installing a machine and pressing the button.

- Select the right machine type for your part size and shape.

- Match abrasive type and size to the material.

- Keep the wheel and separator in good condition.

From field experience: a well-adjusted machine can reduce abrasive consumption by 10–20% and cut cleaning time by nearly one-third. Skilled operators and regular maintenance are just as important as the machine itself.

Main Application Fields

Casting and Forging

In foundries, shot blasting is standard for removing sand, oxide scale, and burrs from cast iron and steel castings. This ensures dimensional accuracy before machining and improves the overall appearance of the product. Forged parts also require blasting to clean scale and prepare surfaces for heat treatment or coating.

Steel Plates and Heavy Industry

Steel mills and shipyards use large industrial shot blasting machines to clean steel plates, beams, and profiles. Removing rust and scale improves welding quality and coating adhesion, which is critical in shipbuilding, bridge construction, and pressure vessel manufacturing.

Automotive Industry

Automotive production lines use shot blasting to clean chassis components, suspension arms, gears, and other parts. The process not only removes surface impurities but also improves fatigue resistance, which is vital for safety-critical components.

Aerospace Components

Although aerospace parts often require precise handling, smaller components such as brackets, fasteners, and turbine blades benefit from controlled shot blasting. The process enhances fatigue life and ensures consistent surface conditions before coating or assembly.

Machinery Manufacturing and Hardware

Shot blasting is widely applied to general machinery parts, valves, bearings, and hardware products. It removes welding slag, scale, and burrs, ensuring stable surface quality and extending service life.

Construction and Infrastructure

In bridge, tunnel, and pipeline maintenance, shot blasting is used to remove old coatings and corrosion, providing a clean base for recoating and extending the service life of critical infrastructure.

Operational Notes and Best Practices

Loading: Do not exceed recommended batch weight; uneven distribution affects cleaning consistency.

Abrasive selection: Match shot size( normally 0.8-1.5mm) and hardness(40-65 HRC) to material; soft alloys require softer shots.

Wheel maintenance: Check wheel balance and wear regularly; worn wheels reduce cleaning efficiency.

Dust and recovery system: Keep separators and filters clean to prevent contamination of shots.

Trial runs: For new materials or thin-walled parts, perform test runs to determine optimal blasting parameters.

Common Faults and Troubleshooting

| Fault | Possible Cause | Engineer’s Action |

|---|---|---|

| Poor cleaning, rust/scale remains | 1. Insufficient shot flow 2. Worn blades 3. Low separator efficiency, dust contamination | Adjust shot flow valve; check blade thickness and replace; clean separator screens and adjust airflow |

| Uneven blasting, uncleaned areas | 1. Wrong blasting angle 2. Workpiece not moving correctly | Adjust impeller angle; check conveyor/tumble/hanger system |

| Excessive vibration or noise | 1. Uneven wear on blades or liners 2. Rotor imbalance 3. Loose bolts | Replace worn parts; rebalance rotor; tighten all bolts |

| High shot consumption | 1. Shot too hard, breaks quickly 2. Excess airflow carries shots away 3. Poor sealing of recovery system | Use proper hardness shot (40–55 HRC typical); adjust air volume; check seals and pipes |

| Poor dust collection, dust leakage | 1. Filter cartridges clogged or damaged 2. Fan underperforming 3. Pipeline leakage | Clean or replace filters; check fan motor; repair pipeline leaks |

| Workpiece dents or deformation | 1. Shot size too large 2. Blasting time too long or wheel speed too high | Use smaller shot (0.6–1.0 mm); shorten cycle or reduce wheel speed |

| Motor tripping frequently | 1. Overload at blasting wheel 2. Bearing jammed or poor lubrication | Check if shot flow exceeds limit; inspect bearings, add grease |

Conclusion

Shot blasting machine is important equipment in metal process.

It can remove rust, oxide and molding sand.

It also makes surface rough, good for painting and welding.

In some case, blasting improve fatigue strength of parts.

Different type machine use for different workpiece:

- Tumble type for small parts in batch.

- Roller conveyor type for plate and profile.

- Hanger type for big and complex casting.

Blasting result depend on machine, abrasive and operation.

Proper shot flow, blasting time and wheel speed give better surface quality.

Good maintenance and skilled worker can save abrasive and reduce cost.