Buying a molding machine is easy. Buying the right one is engineering.

A Hydraulic Multi-Piston Sand Molding Machine is a significant investment. If the specifications don’t align with your specific foundry process, you’re looking at years of inefficient production and high scrap rates.

Introduction

Green sand molding remains the backbone of modern foundry production due to its low cost, high adaptability, and suitability for mass casting. As casting requirements grow in precision and productivity, the hydraulic multi-piston green sand molding machine has become a preferred solution for medium and large-scale foundries.

However, selecting the right molding machine is not simply a matter of price comparison. From an engineering perspective, machine performance, compaction stability, hydraulic reliability, and structural strength directly influence mold quality and long-term production cost. This article outlines the key technical factors that foundry engineers should evaluate before making a purchase decision.

1. Molding Size Range and Flask Compatibility

The first step in machine selection is confirming the required molding size range. Hydraulic multi-piston molding machines are manufactured according to specific flask dimensions. Improper matching between machine table size and flask system can cause inefficient compaction or unnecessary energy consumption.

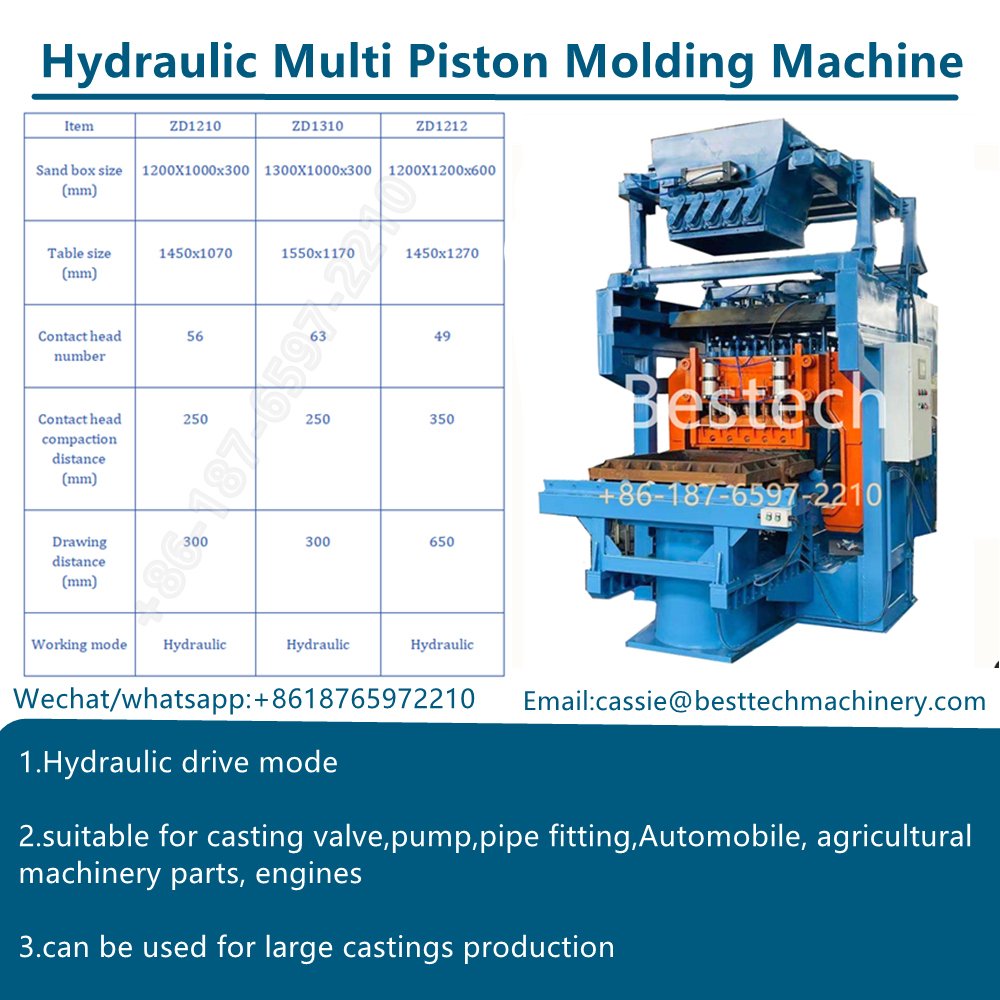

Engineering reference parameters:

- Common flask inner size: 400×300 mm to 1200×1000 mm

- Max squeeze stroke: 150–350 mm

- Table load capacity: 1–8 tons

Selection suggestion:

- Define current product casting dimensions

- Consider future product expansion

- Confirm flask interchangeability with existing lines

A well-matched flask system ensures consistent mold thickness and dimensional accuracy.

2. Compaction Pressure and Multi-Piston Distribution Design

Uniform sand density is the core advantage of multi-piston squeeze technology. Unlike single-cylinder jolt-squeeze machines, multi-piston systems distribute pressure evenly across the mold surface.

Typical technical parameters:

- Hydraulic working pressure: 10–16 MPa

- Individual piston diameter: 80–160 mm

- Total squeeze force: 300–1500 kN

- Mold hardness range: 85–92 (AFS hardness)

Engineering focus points:

- Number and layout of squeeze pistons

- Real mold hardness test reports

- Pressure holding stability during squeeze

Excessive pressure may cause pattern wear or sand crushing. Uniform pressure distribution is more important than absolute force value.

3. Hydraulic System Stability and Oil Circuit Design

The hydraulic system is the “heart” of the molding machine. Poor hydraulic design leads to unstable pressure, oil leakage, and high maintenance cost.

Recommended hydraulic design features:

- Proportional pressure control valves

- Variable displacement or servo pump system

- Oil temperature control unit

- Filtration accuracy ≤ 25 μm

Applicable standards:

- ISO 4413: Hydraulic fluid power — General rules and safety requirements

- CE Machinery Directive 2006/42/EC

Stable hydraulic performance ensures repeatable compaction cycles and extends machine service life.

4. Sand Filling and Pre-Compaction Method

Even with strong squeeze force, poor sand filling causes internal mold defects such as soft spots and sand collapse.

Modern hydraulic multi-piston molding machines typically adopt:

- Automatic sand feeding hopper

- Vibratory or aeration sand filling

- Pre-compaction plate before final squeeze

Engineering benefit:

- Improves sand flowability

- Reduces trapped air inside mold

- Lowers impact load on squeeze cylinders

Proper filling technology is critical for consistent mold density.

5. Automation Level and Production Efficiency

For medium and high-output foundries, automation directly affects productivity and labor cost.

Automation options include:

- Automatic flask conveying

- Mold turnover device

- Pattern lifting mechanism

- PLC + HMI recipe control

Typical production capacity:

- 60–120 molds/hour for medium size machines

- Cycle time: 25–60 seconds/mold

Choosing a modular automation system allows future upgrades without replacing the main machine.

6. Machine Frame Rigidity and Structural Design

Multi-piston squeeze force generates high reaction loads. Weak frame structures may deform over long-term operation, affecting mold accuracy.

Engineering evaluation points:

- Frame material: ductile iron or welded steel structure

- Guide column diameter: ≥ 120 mm

- Column surface hardness: HRC 50–55

- Finite element stress analysis design verification

Rigid structural design ensures stable mold thickness and long-term dimensional repeatability.

7. Energy Consumption and Maintenance Cost

Hydraulic molding machines are traditionally energy-intensive. Modern energy-saving designs significantly reduce operating cost.

Energy-saving features:

- Servo motor-driven hydraulic pump

- Pressure holding circuit with low energy loss

- Intelligent standby mode

Typical power consumption:

- Installed power: 15–75 kW

- Average operating power reduction: 20–35% with servo system

Maintenance-friendly design with standard seals and readily available spare parts is equally important.

8. Compliance with Industry and Safety Standards

Reliable manufacturers design equipment based on recognized international standards to ensure safety and export compliance.

Common applicable standards:

- ISO 9001: Quality management system

- ISO 4413: Hydraulic system safety standard

- EN 1247: Foundry machinery safety requirements

- CE conformity for European market

Machines built under these standards offer better operational safety and easier certification for global projects.

9. Supplier Engineering Support and Commissioning Experience

A molding machine is part of a complete molding line, not a stand-alone product.

Professional suppliers should provide:

- Installation and alignment guidance

- Mold hardness calibration

- Operator training

- Preventive maintenance planning

Engineering support during commissioning greatly reduces trial-production scrap rate and downtime.

Conclusion

Selecting a hydraulic multi-piston green sand molding machine is a technical decision that directly impacts casting quality, production efficiency, and long-term operational cost. By carefully evaluating molding size compatibility, compaction system design, hydraulic stability, automation options, frame rigidity, and standards compliance, foundries can secure a reliable and cost-effective molding solution.

A properly selected machine becomes not only a piece of equipment, but a long-term production partner.