In high-precision casting—whether it’s engine blocks or complex valves—the Sand Core Shooting Machine is the silent guardian of internal quality. A poor selection here leads to gas defects, dimensional drift, and broken cores.

Sand core shooting machine is a foundry machine used to produce sand cores, which form internal cavities or hollow sections inside metal castings.

Introduction

In modern foundry production, sand cores are essential for forming internal cavities and complex structures in castings. Core accuracy, surface finish, and strength directly influence final casting quality and rejection rate. Therefore, selecting a reliable sand core shooting machine is not only a purchasing decision, but a key engineering choice that affects production stability and long-term operating cost.

Although sand core shooting machines appear simple in operation, their performance depends on compressed air stability, sand feeding control, box sealing precision, and structural rigidity. This article introduces the key technical factors that foundry engineers should consider when selecting a sand core shooting machine.

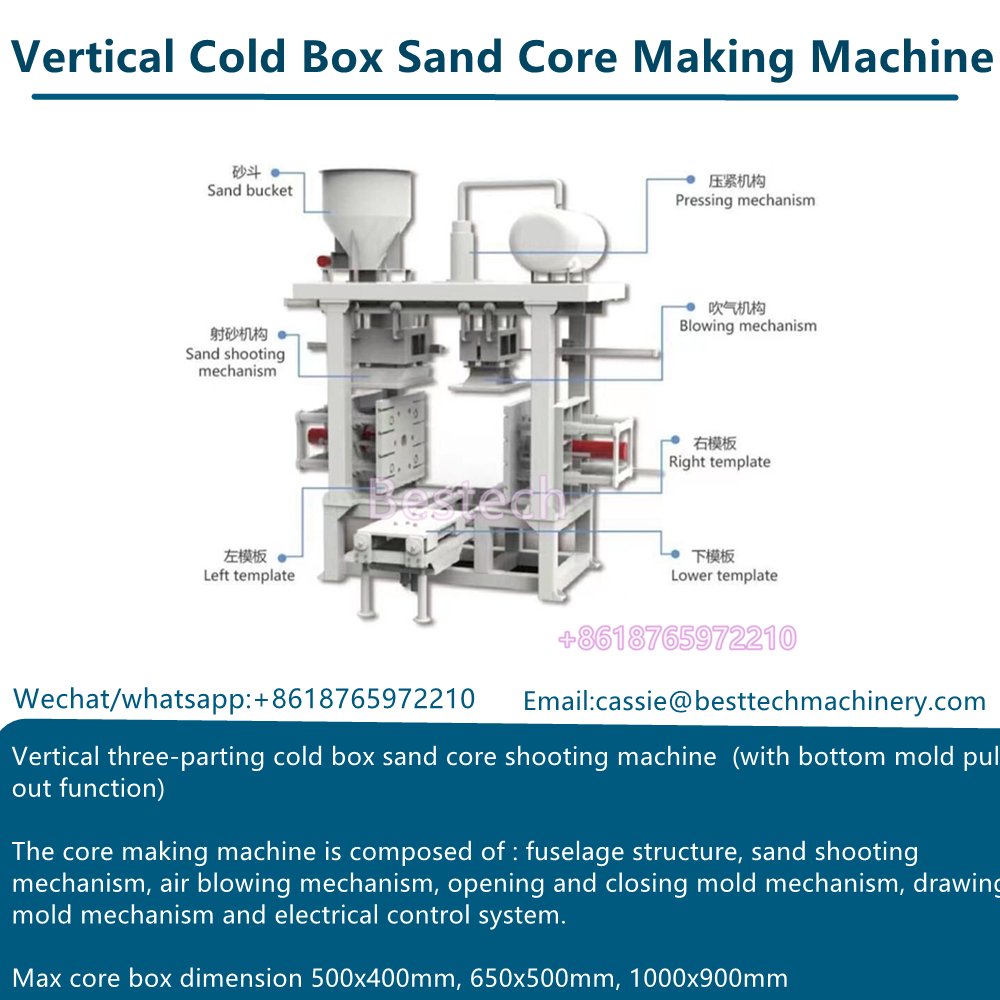

1. Core Size Range and Shooting Box Compatibility

The first step is confirming required core dimensions and shooting box size. Improper matching between machine and core box leads to inaccurate cores, frequent adjustments, and lower productivity.

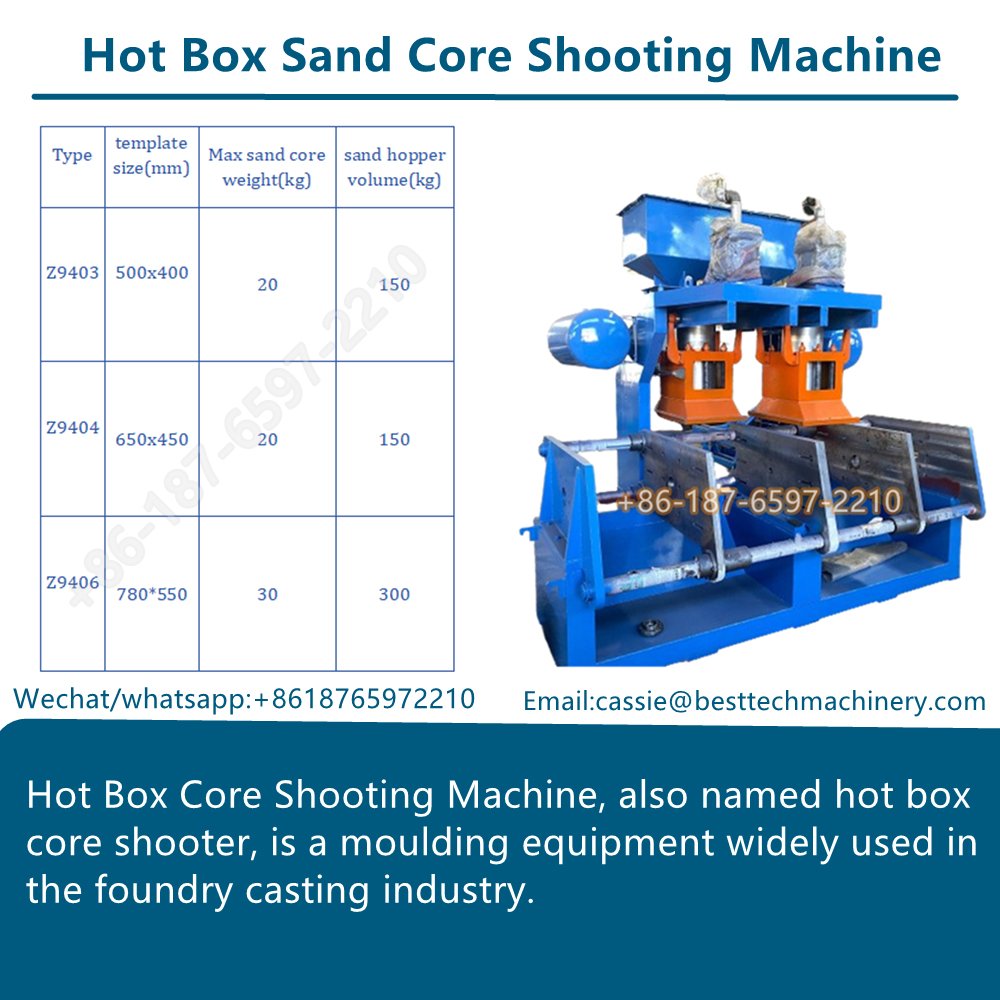

Reference Technical Parameters

- Common shooting box size: 300 × 300 mm to 1400 × 1400 mm

- Core thickness range: 20 – 300 mm

- Shooting stroke: 100 – 400 mm

- Core positioning repeatability: ≤ ±0.1 mm

Engineering Considerations

- Define current and future core product sizes

- Confirm quick-change shooting box system

- Check alignment accuracy of guide columns

A properly matched shooting box system ensures dimensional consistency and short setup time.

2. Sand Shooting Pressure and Compressed Air Stability

Sand shooting relies on high-speed compressed air to fill the shooting box uniformly. Unstable air pressure causes incomplete filling, weak core edges, and density variation.

Typical Operating Parameters

- Working air pressure: 0.5 – 0.8 MPa

- Air consumption: 0.5 – 2.5 m³ per shot

- Shooting time: 0.2 – 1.0 seconds

- Air tank volume: 0.3 – 1.5 m³

Engineering Focus Points

- Air reservoir pressure stability

- Fast-response solenoid or pneumatic valves

- Optimized air pipeline layout

Stable air delivery ensures uniform sand compaction and repeatable core strength.

3. Sand Feeding and Flow Control System

Consistent sand feeding is essential for uniform core density.

Common Design Features

- Automatic sand hopper with level sensor

- Sand feeding gate with adjustable opening

- Anti-bridging vibration device

Engineering Benefits

- Prevents sand blockage

- Controls sand quantity per shot

- Reduces operator intervention

Reliable sand flow control improves core quality and production efficiency.

4. Core Box Sealing and Clamping Precision

Air leakage during shooting results in sand flash, poor core edges, and material waste.

Key Engineering Checkpoints

- Core box closing force stability

- Sealing strip design and wear resistance

- Guide column precision and rigidity

- Locking mechanism repeatability

A strong and precise clamping system ensures tight box sealing and clean core geometry.

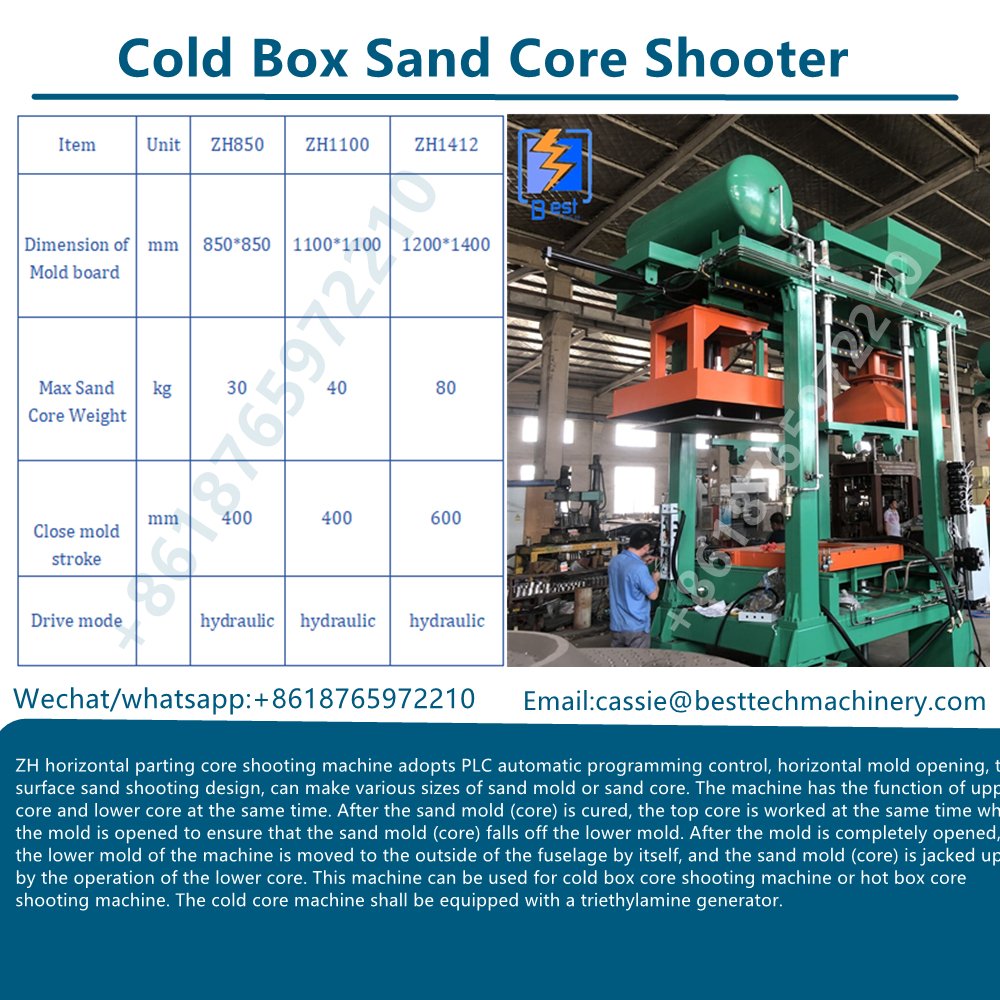

5. Resin Binder Mixing and Curing System (Cold Box Process)

For cold box core shooting machines, binder mixing accuracy and gas curing efficiency directly determine core strength.

Typical Process Parameters

- Resin dosing accuracy: ±0.1%

- Sand-resin mixing time: 20 – 60 seconds

- Amine gassing time: 1 – 5 seconds

- Core bending strength: ≥ 1.5 MPa

Engineering Considerations

- Automatic resin metering system

- Uniform mixing blade design

- Gas distribution plate layout

- Exhaust gas filtration system

Stable resin and gassing systems ensure strong and dimensionally stable cores.

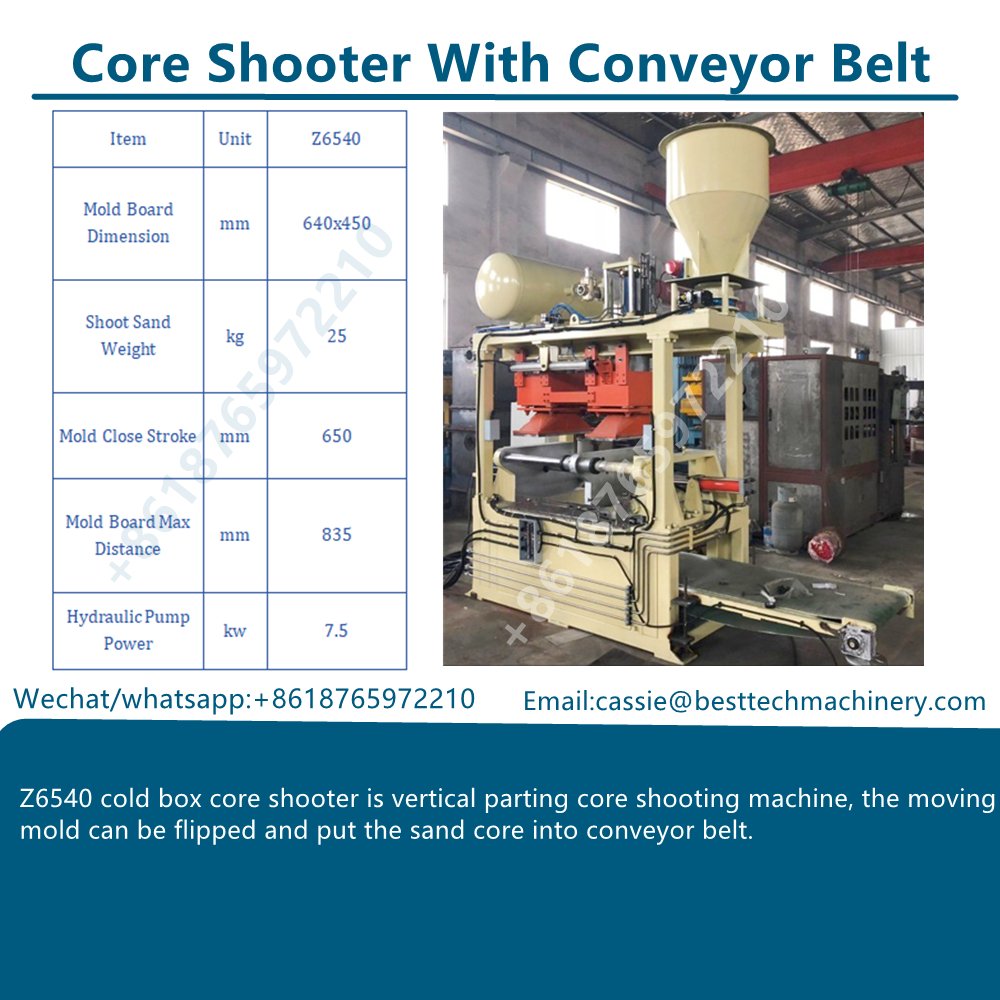

6. Automation Level and Production Capacity

Automation reduces labor cost and improves consistency in mass core production.

Available Automation Options

- Automatic core ejection system

- Conveyor transfer line

- Robot core handling

- PLC + HMI control system

Typical Output Range

- 40 – 150 cores per hour (depending on core size)

Modular automation allows future expansion without replacing the main machine.

7. Machine Frame Rigidity and Structural Strength

High-speed sand shooting creates impact loads on machine structure. Weak frames cause vibration, misalignment, and long-term precision loss.

Engineering Evaluation Points

- Welded steel frame with stress-relief treatment

- Guide column diameter ≥ 80 mm

- Position repeatability ≤ ±0.1 mm

- Structural verification by finite element analysis (FEA)

Rigid structural design ensures stable operation and consistent core accuracy.

8. Energy Consumption and Maintenance Design

Compressed air and binder systems are major energy consumers. Efficient design reduces operating cost.

Energy-Saving Measures

- Optimized air tank sizing

- Quick-response valves reducing air waste

- Automatic standby mode

Maintenance Considerations

- Easy access to shooting tank

- Standardized sealing components

- Simple cleaning structure

Maintenance-friendly design extends service life and reduces downtime.

9. Safety and International Standards Compliance

A professional sand core shooting machine should meet international safety and quality standards for global foundry projects.

Applicable Standards

- ISO 9001 – Quality Management System

- ISO 4414 – Pneumatic System Safety Requirements

- EN 1247 – Foundry Machinery Safety Standard

- CE Machinery Directive 2006/42/EC

Standards-based manufacturing ensures safe operation and export certification compliance.

Conclusion

Selecting a sand core shooting machine is a critical engineering decision that influences core quality, casting precision, production efficiency, and long-term operational cost. By evaluating core size compatibility, compressed air stability, sand flow control, sealing accuracy, automation capability, structural rigidity, and standards compliance, foundries can secure reliable and cost-effective core production solutions.

A properly selected sand core shooting machine becomes the foundation for high-quality and stable casting manufacturing.