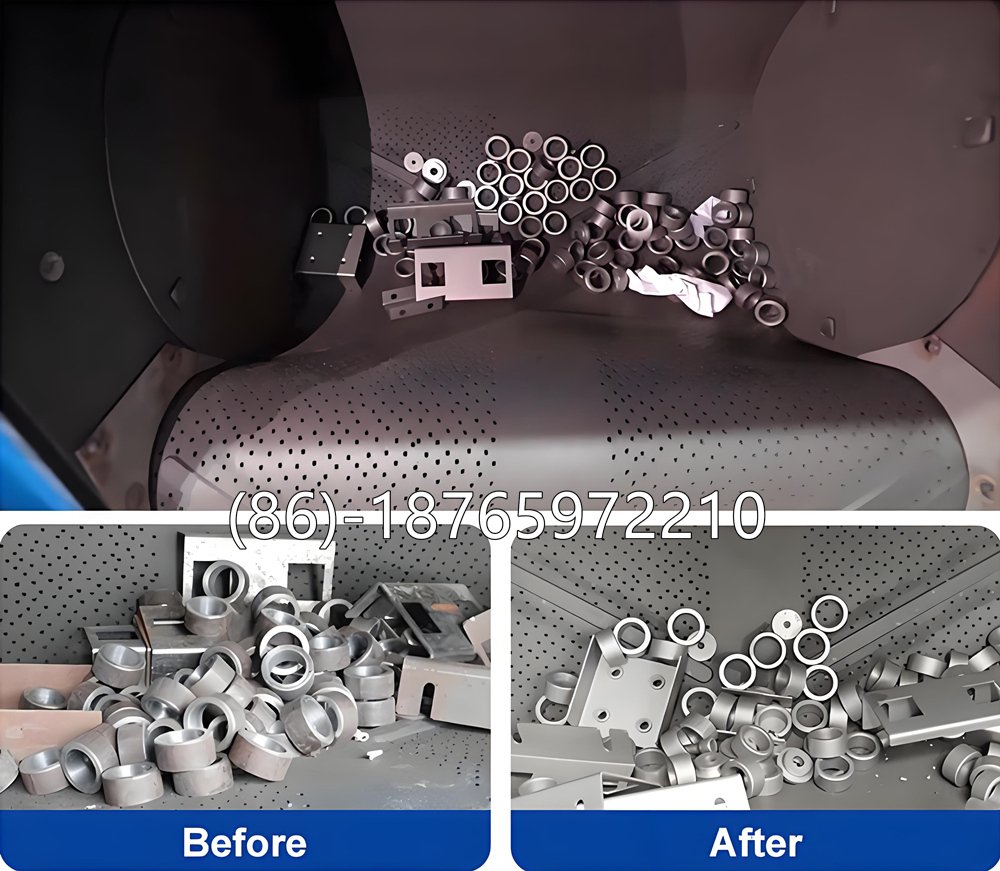

Tumble shot blasting machine is a vital piece of equipment for cleaning, descaling, and strengthening small to medium-sized workpieces (5kg – 40kg) in foundries, automotive, forging, and general metalworking industries. Selecting the right machine is crucial to ensure both productivity and cost-effectiveness. Below are the key factors engineers and plant managers should consider when making a decision.

1. Workpiece Characteristics

Size and Weight:

- Machines are designed with different drum capacities. Lighter machines such as Q324 model can handle 50–100 kg per batch, while larger models such as Q3220 can handle 1000kg per batch.

Material Type:

Steel, cast iron, aluminum, and non-ferrous parts require different abrasive selections.

🔹 Steel Parts

- Common Abrasives: Steel shot (spherical) or steel grit (angular).

- Why: Steel parts are strong and can withstand aggressive impact. Steel shot provides smooth surfaces, while grit creates more profile (roughness) for coatings.

- Applications: Rust removal, descaling, peening (strengthening).

🔹 Cast Iron Parts

- Common Abrasives: Steel shot or chilled iron grit.

- Why: Cast iron is brittle but hard; chilled iron grit is cheap and effective for heavy descaling. Steel shot is better if surface peening is required.

- Applications: Removing molding sand, scale, or oxide layers in foundries.

🔹 Aluminum Parts

- Common Abrasives: Glass beads or aluminum oxide.

- Why: Aluminum is soft and prone to deformation. Steel abrasives may damage or embed into the surface. Glass beads produce a smooth, satin finish, while aluminum oxide offers more cutting power without contamination.

- Applications: Cosmetic finishing, cleaning without dimensional change, preparing for coating or anodizing.

🔹 Non-Ferrous Metals (Copper, Brass, Zinc, etc.)

- Common Abrasives: Glass beads, plastic media, or aluminum oxide.

- Why: Non-ferrous alloys are softer and sensitive to impact. Non-metallic abrasives prevent surface damage and avoid ferrous contamination.

- Applications: Surface cleaning, deburring, finishing decorative parts.

Shape and Fragility:

- Complex, thin-walled, or fragile components need careful handling to avoid deformation or damage during tumbling.

2. Machine Capacity and Productivity

- Batch Volume: Choose a machine that matches your daily production output. Overloading reduces cleaning quality, while underloading wastes energy.

- Cycle Time: Shorter blasting cycles improve efficiency but must still provide uniform cleaning.

- Automation Options: Automatic loading, unloading, and abrasive circulation systems can save labor and improve consistency.

3. Abrasive Type and Consumption

- Abrasive Selection: Steel shot, grit, or other abrasives vary in aggressiveness, cost, and wear resistance.

- Consumption Rate: Machines with efficient abrasive recycling systems reduce operating costs.

- Dust Collection: A reliable dust collector ensures safe operation and compliance with environmental standards.

4. Drum Design and Material

- Belt Type: Rubber belts are common for lighter, more delicate parts, while steel belts are suitable for heavier or sharp-edged components.

- Durability: The inner lining of the drum should resist wear and protect both the parts and the machine itself.

- Loading Method: Consider whether a manual, hydraulic, or conveyor-assisted loading system fits your workflow.

5. Maintenance and Spare Parts Availability

- Ease of Access: Machines designed with accessible blast wheels, belts, and filters minimize downtime.

- Spare Parts Supply: Availability of wear-resistant parts such as blast wheel blades, liners, and belts is critical for long-term operation.

- Service Support: Reliable after-sales support from the manufacturer or distributor helps maintain consistent performance.

6. Energy Efficiency and Operating Cost

- Power Consumption: Energy-efficient blast wheels lower running costs.

- Abrasive Efficiency: Well-designed recycling systems minimize waste.

- Labor Requirements: Automated controls reduce operator workload and improve overall efficiency.

7. Safety and Compliance

- Protective Design: Ensure the machine has interlocks, emergency stop systems, and adequate sealing to prevent abrasive leakage.

- Dust and Noise Control: Compliance with workplace safety regulations is essential for both operators and the surrounding environment.

Conclusion

Choosing the right tumble shot blasting machine requires balancing workpiece requirements, productivity goals, and operating costs. By carefully evaluating factors such as workpiece characteristics, machine capacity, abrasive system, maintenance needs, and safety features, companies can select a machine that delivers reliable cleaning performance while reducing long-term expenses.