Resin Sand Molding Reclamation Line

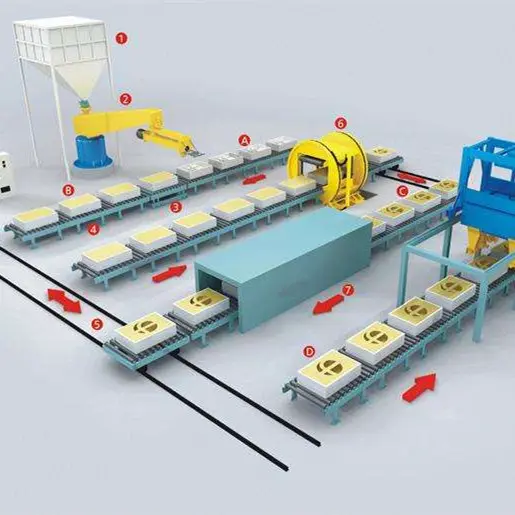

No Bake Resin Sand Molding Line Overview

No bake resin sand casting equipment is suitable for the production of multiple varieties of cast iron, cast steel and non-ferrous castings, meeting the process requirements of self-hardening sand such as furan resin sand, alkaline phenolic resin sand, esterified water glass sand, etc.

Resin sand no bake molding line is a molding and core making technology which the mould and core sand will be self-harded in some time in the flask when added in certain agent.

The great characteristic is that the room temperature the resin sand can be self-harded. It fits the single piece, small batch, various medium and large scale casting’mould and core, widely used in the tool, general, heavy, shipbuilding, locomotive industry.

Technical Specifications

model | SWT-10 | SWT-20 | SWT-30 | SWT-40 |

productivity(t/h) | 10 | 20 | 30 | 40 |

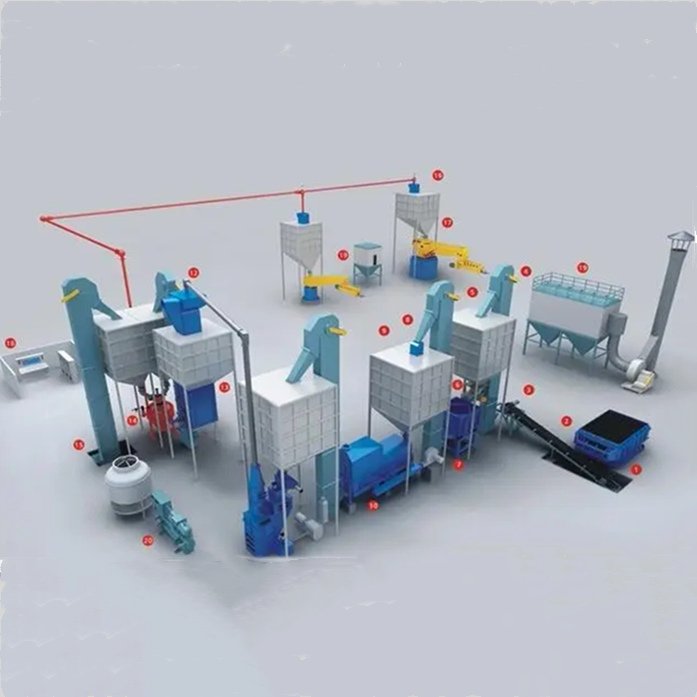

Furan Resin Sand Reclamation Line Features

It is supplemented by falling sand, crushing, magnetic separation, cooling, conveying, and sand mixing equipment to form a complete set of resin sand recycling treatment equipment, which is mainly suitable for producing cast iron, cast steel, and total non-ferrous castings in the foundry.

The resin sand process uses low nitrogen, nitrogen-free furan resin or alkali phenolic resin as a binder, a curing agent as a hardener, and the sand mould at an average temperature. This process is advanced, the casting quality is high, and the used sand recovery rate is high.

The eddy current and scrubbing regeneration methods are mainly used to remove the inert film on the surface of the old sand, which has achieved the purpose of regeneration.

The above set of regeneration treatments is compact in structure and reasonable in design so that the regenerated sand is qualified.

Modeling enlarges the moulding area and saves the conveying volume of the moulding sand.

Deal with a top suction dedusting hood is adopted above the grid, and a mechanical rotary back-blown bag type dust removal is set for the primary dust source to ensure dust emission standards and JB9078-96 dust emission concentration standards.

Advanced Japanese original PLC programmable controller, automatic control, reliable interlocking protection system for each operating equipment, making the whole line easy to operate, monitor, restrict and fully protect.

Have Any Questions?

If you have any questions or need more information about our shot blasting machines or services, don’t hesitate to reach out!

Categories

Whatever your needs, we’re here to make it happen.

-The resin sand casting process, conceptually similar to sand casting process, has

peculiarities as the type of elements used in the making of the mold.

-It takes, phenolic resins and urea-furan which, together with a chemical catalyst, are mixed before forming to the sand.

-This mixture generates a significant hardening of the sand, considerably improving the quality of castings products both in terms of surface quality (with a reduction of the surface roughness), both with respect to the design dimensions, while also avoiding the possible breakage of the mold during the pouring phase.

Our Products

Foundry Machine

We provide advanced casting equipment, including molding, sand mixing, core shooting, and recycling technologies, all designed to help you improve casting precision, reduce waste, lower costs, and achieve higher efficiency and superior results for your production.

Resin Sand Mixer

Resin sand mixer machine is widely used for mixing furan resin no-bake sand, suitable for sand mixing and core making of medium and large castings.

Automatic Flaskless Molding Machine

This machine automates molding without flasks, improving speed, precision, and efficiency while reducing labor costs and ensuring high-quality casting.

Green Sand Mixer

The machine is mainly used for foundry sand mixing, can be used for single sand ,and mixed fired mold sand, self-hardening sand, face sand and core sand.

Hot Box Core Shooter

Hot Box Core Shooting Machine, also named hot box core shooter, is a moulding equipment widely used in the foundry casting industry.

Jolt squeeze molding machine

This machine uses jolt and squeeze action for precise, uniform molds, helping you improve efficiency, reduce waste, and enhance casting quality.

Multi Piston Molding Machine

High pressure multi piston molding machine adopt hydraulic compaction pressure is for medium and large cast iron castings.

Resin Sand Molding Reclamation Line

Resin sand molding reclamation line is a system used in foundries to recover and reuse resin-coated sand after it has been used in the molding and casting process.

Green Sand Molding Reclamation Line

This system efficiently recycles clay sand molds, reducing material costs and waste, helping you improve production efficiency and maintain consistent mold quality.

Cold Box Core Shooting Machine

This machine is used to produce sand cores for metal casting processes. It operates based on the cold box process, a method where sand is mixed with a resin binder and then hardened or cured by introducing a gaseous catalyst, usually at room temperature

- 30+ Years of Expertise

- Expert Support

- Cutting-Edge Technology

- Cost-Effective Solutions

- Industry-Leading Expertise

How Can I Help You?

We offer tailored solutions to meet your specific needs. Whether it’s optimizing your production line, providing technical expertise, or delivering custom equipment, our team is dedicated to helping you achieve maximum efficiency and quality. Let us know how we can support your business.