Tumble shot blasting machine is one of the most commonly used shot blasting systems in foundries, forges, and metal workshops.

In the workshop, the tumble shot blasting machine is reliable, but it can also be dangerous if not handled correctly.

Key Points Remind Operators To Follow

1. Before Starting

- Check drum, belt, and door seals – no cracks, no gaps.

- Make sure the blast wheel and liners are tight, no abnormal noise when spinning.

- Confirm abrasive level in the hopper. Clean out large scraps.

- Verify dust collector is running, pressure is in the normal range.

2. During Operation

- Do not overload the drum. Stick to rated capacity.

- Never put fragile or oversized parts inside – they break belts and jam tumbling.

- Ensure the door is fully locked before pressing start.

- Watch the parts tumbling – if stuck, stop and fix.

- Do not open covers or reach inside while running.

3. Dust & Abrasive Handling

- Dust is a fire and health risk – keep the collector filters clean.

- Keep the abrasive recycling system clear of scrap, sand, or broken parts. Blockages cause unsafe operation.

4. Maintenance Rules

- Always follow lockout/tagout – power off, air released before any work.

- Blast wheel parts (blades, impeller, liners) – change only when fully stopped.

- Stick to preventive maintenance schedule. Don’t wait for breakdowns.

5. Emergencies

- Know where the emergency stop buttons are – test them regularly.

- Fire extinguishers must be near the machine. Dust and sparks are a bad mix.

- First aid kit available – especially for eye or skin injuries.

Final Note

This machine does its job well, but it is not forgiving. Respect the load limits, wear your PPE, and never bypass safety checks. If anything doesn’t sound right, stop and inspect before continuing.

Tumble Shot Blasting Machine – Overview

What It Is

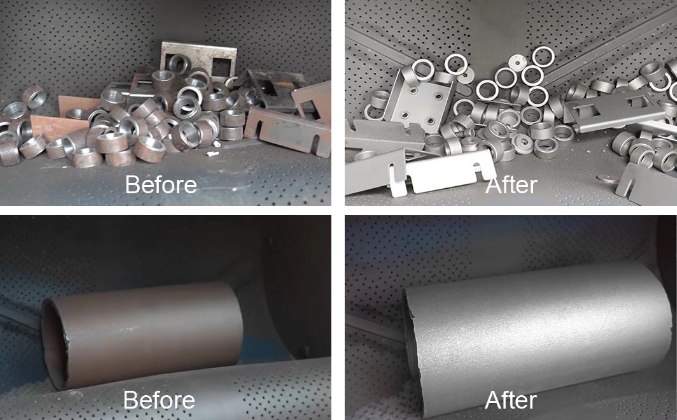

- A batch-type metal surface cleaning machine.

- Workpieces are loaded into a rubber or steel belt drum.

- As the drum rotates, parts tumble over each other.

- High-speed abrasive (steel shot or grit) from the blast wheel cleans rust, scale, sand, or burrs.

Where It’s Used

- Foundry – castings cleaning, sand removal.

- Forge & Heat Treatment – scale removal.

- Automotive & Fabrication – descaling, paint prep, or deburring.

- Best for small and medium parts (100kg ~1000kg each), especially irregular shapes.

Key Features

- Continuous tumbling ensures all surfaces are exposed.

- Batch operation – simple loading/unloading.

- Abrasive recycling system keeps costs down.

- Dust collector prevents airborne dust.

- Rubber belt type → gentle on delicate parts.

- Steel belt type → suited for heavy, sharp-edged castings.

Advantages

- Uniform cleaning quality.

- High productivity for bulk parts.

- Low labor cost compared to manual cleaning.

- Suitable for preparing surfaces before painting or coating.

Why Choose a Tumble Shot Blasting Machine?

✅ Efficient Cleaning – Uniform surface treatment for castings, forgings, and small metal parts.

✅ Cost-Effective – Automatic abrasive recycling reduces operating costs.

✅ Versatile – Handles irregular shapes and mixed batches with ease.

✅ Durable – Steel or rubber belt options for both heavy-duty and delicate parts.

✅ Production-Friendly – Fast cycle times, reliable performance, and easy maintenance.

👉 Tumble Shot Blasting Machine the smart choice for foundries, automotive, and metalworking industries.