High-Speed Production meets Low-Cost Operation.

The advantage of Cold Box Technology is clear: Instant curing and unmatched dimensional stability. But is your machine performing at its maximum ROI?

Cold box sand core shooting machine is a high-efficiency foundry machine that forms strong sand cores by shooting resin sand into a core box and curing it instantly with amine gas at room temperature.

Introduction

Cold box sand core shooting machines are widely used in modern foundries for producing high-strength and high-precision sand cores. This technology is especially suitable for complex internal cavities in automotive, valve, pump, and machinery castings.

Compared with traditional hot box technology, the cold box process offers faster curing speed, higher core strength, and lower energy consumption. However, stable operation strongly depends on correct working principles and proper maintenance management.

This article explains the working principle, key technical parameters, and practical maintenance methods of cold box sand core shooting machines from an engineering point of view.

1. Working Principle of Cold Box Sand Core Shooting Machine

The cold box process is based on compressed air sand shooting and amine gas chemical curing at room temperature.

1.1 Sand Preparation and Resin Mixing

Silica sand is mixed with cold box resin binder in a continuous or batch sand mixer. Uniform resin coating is essential for stable curing and core strength.

Typical sand parameters:

- Sand grain size: 50–70 AFS

- Resin addition: 0.8–1.5% (by sand weight)

- Sand moisture content: ≤ 0.3%

- Mixing time: 60–120 seconds

Good sand preparation directly affects core surface quality and strength.

1.2 Sand Shooting Process

After the core box is closed and clamped, compressed air shoots the resin-coated sand into the core cavity through the shooting head.

Typical shooting parameters:

- Shooting pressure: 0.5 – 0.8 MPa

- Shooting time: 0.2 – 1.0 s

- Filling density: ≥ 98%

- Air consumption: 0.3 – 0.6 m³ per shot

High and stable shooting pressure ensures dense sand filling, especially for thin-wall and complex cores.

1.3 Amine Gas Curing Process

Once sand filling is completed, amine gas is injected into the core box. The gas reacts with the resin binder and causes rapid chemical hardening at room temperature.

Typical curing parameters:

- Gas curing time: 1 – 5 seconds

- Gas purge time (air blowing): 5 – 10 seconds

- Full core hardening time: 10 – 20 seconds

- Core bending strength: ≥ 2.5 MPa

This chemical curing process eliminates the need for heating systems and reduces energy consumption.

1.4 Exhaust and Gas Treatment

After curing, residual gas is extracted through exhaust channels and sent to a gas neutralization or treatment system.

Proper exhaust design ensures:

- Operator safety

- Environmental compliance

- Stable curing results

Blocked exhaust channels can cause poor curing and strong odor problems.

1.5 Core Ejection and Handling

After curing, the core box opens and ejector pins push the hardened core out of the box. The core can be manually removed or automatically transferred by robot.

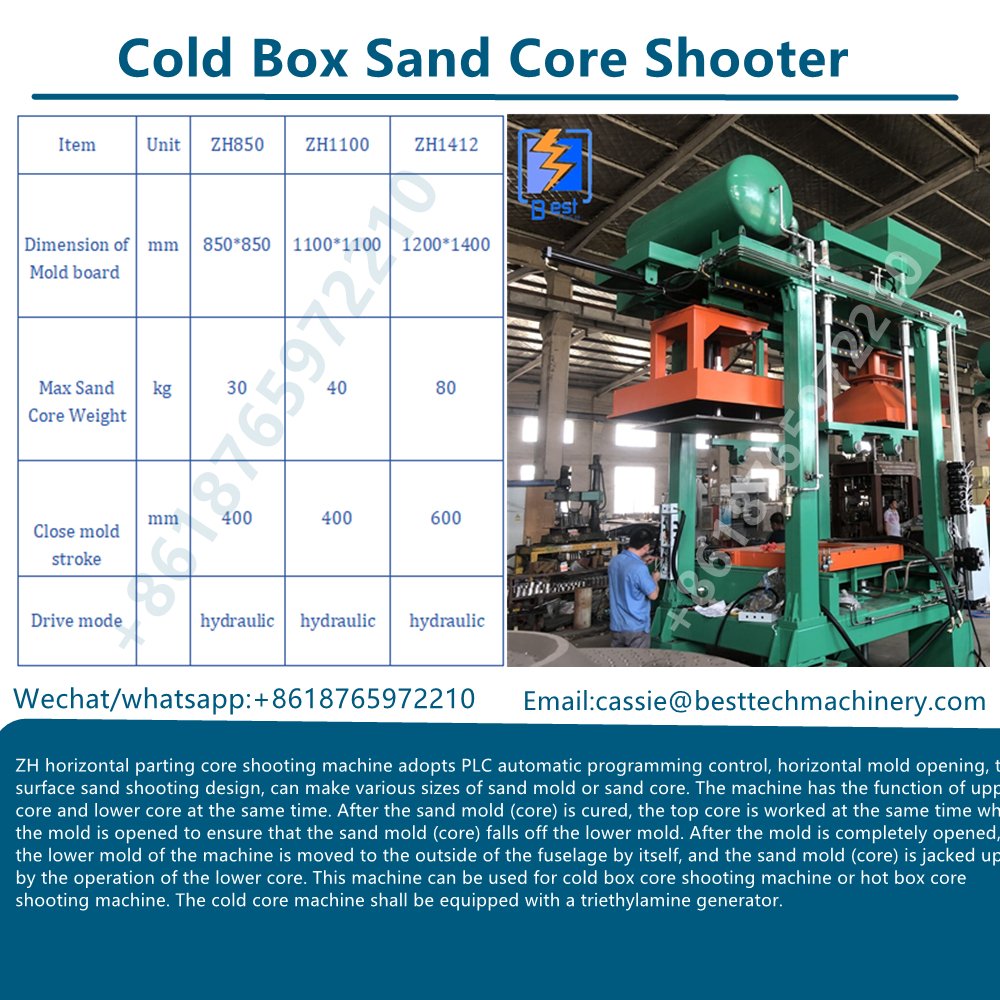

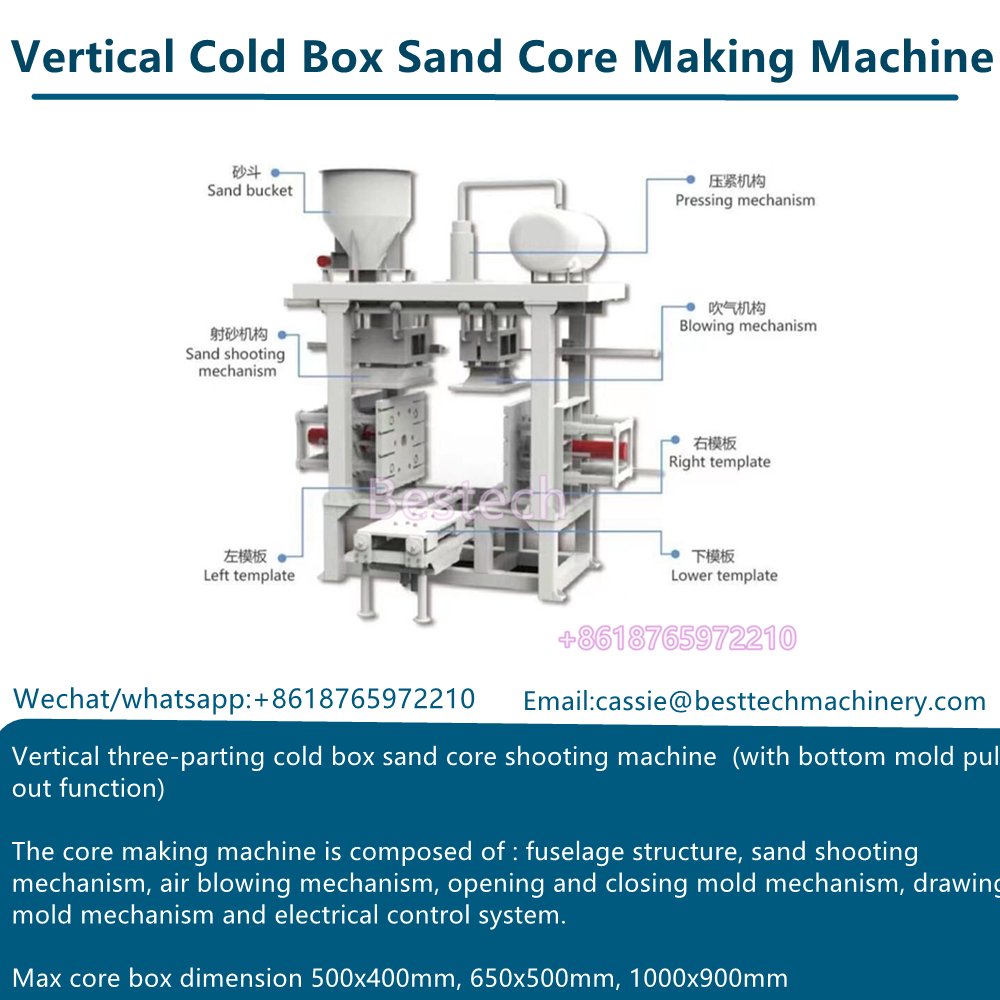

2. Main Structure of Cold Box Core Shooting Machine

A standard cold box sand core shooting machine consists of:

- Sand hopper and shooting head

- Core box clamping unit

- Gas injection and control system

- Exhaust and ventilation system

- Pneumatic and hydraulic systems

- PLC control system with HMI

All systems must work in coordination to ensure stable and repeatable core quality.

3. Maintenance Methods of Cold Box Sand Core Shooting Machine

Regular maintenance is essential to reduce downtime and ensure long service life.

3.1 Daily Maintenance

- Clean sand residue from shooting head and core box

- Check compressed air pressure stability

- Inspect gas pipes and joints for leakage

- Clean exhaust filters

- Observe core surface quality and strength

3.2 Weekly Maintenance

- Inspect pneumatic valves and cylinders

- Check seals and O-rings

- Clean shooting nozzles

- Check vent holes in core box

- Verify sensor signals and limit switches

Blocked vent holes are a common reason for sand filling defects.

3.3 Monthly Maintenance

- Inspect amine gas injection valves

- Check exhaust fan performance

- Test emergency stop and safety interlocks

- Inspect hydraulic oil level and cleanliness

- Calibrate pressure and flow sensors

3.4 Resin and Sand Management

- Keep resin ratio stable

- Avoid excessive resin addition

- Store resin at recommended temperature

- Prevent sand contamination with moisture or metal dust

Poor sand control is one of the main causes of core defects.

4. Common Problems and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Low core strength | Low resin ratio or short gas time | Adjust resin and curing time |

| Broken cores | Low sand compaction | Increase shooting pressure |

| Rough surface | Dirty core box | Clean and polish core box |

| Strong gas odor | Exhaust system failure | Check ventilation and filters |

| Sand leakage | Worn seals | Replace sealing parts |

5. Safety and Environmental Considerations

Cold box machines must comply with safety and environmental regulations:

- ISO 9001 – Quality Management System

- ISO 4414 – Pneumatic System Safety

- EN 1247 – Foundry Machinery Safety

- CE Machinery Directive 2006/42/EC

Proper gas treatment and ventilation systems are mandatory for safe operation.

Conclusion

The cold box sand core shooting machine operates based on high-pressure sand shooting and amine gas chemical curing. It provides excellent core strength, dimensional accuracy, and high production efficiency.

However, stable performance depends on correct process parameters, proper sand management, and regular maintenance. Understanding the working principle and maintenance methods helps foundries reduce defects, extend equipment life, and ensure safe production.

From an engineering perspective, good maintenance is not a cost, but an investment in long-term productivity and quality stability.