One Machine, Infinite Applications: Is your surface prep flexible enough?

The Hanger Shot Blasting Machine is often called the “Universal Soldier” of the finishing room. From small aluminum die-casts to heavy steel structures, its flexibility is unmatched. But is your operation running at its lowest cost-per-part?

1. Introduction

Hanger shot blasting machine is an important surface treatment equipment widely used in foundry, casting, forging, steel structure, and heavy fabrication industries. It is mainly applied for rust removal, oxide scale cleaning, sand removal, and surface strengthening of medium and large workpieces.

Understanding the working principle and correct maintenance methods of hanger shot blasting machine is critical for improving cleaning quality, reducing maintenance cost, and extending equipment service life.

2. Working Principle of Hanger Shot Blasting Machine

The hanger shot blasting machine cleans workpiece surface by high-speed steel shot impact combined with hanger rotation and movement. Its working principle is based on mechanical centrifugal blasting and closed-loop abrasive circulation.

2.1 Main Structure Composition

A typical hanger shot blasting machine consists of:

- Shot blasting chamber

- Shot blasting wheels

- Hanger and rotation system

- Abrasive circulation system

- Dust collection system

- Electrical control system

Each system works together to ensure stable and efficient blasting operation.

2.2 Workpiece Hanging and Rotation Principle

The workpieces are fixed on hanger hooks and loaded into the blasting chamber by crane or rail system. During blasting, the hanger rotates at a controlled speed. Some designs also include vertical lifting or swinging movement.

This multi-direction movement ensures steel shots can impact the workpiece surface uniformly, especially for complex shapes, blind holes, and welded structures.

2.3 Shot Blasting Wheel Working Principle

The shot blasting wheel is the core component of the machine.

Steel shots enter the control cage and are fed to the rotating impeller. Through centrifugal force, shots are accelerated by blades and thrown onto the workpiece surface at high velocity.

The kinetic energy of steel shots removes rust, oxide scale, sand, and contaminants while also forming a suitable surface roughness for painting or coating adhesion.

2.4 Abrasive Circulation and Separation System

After blasting, used steel shots and debris fall to the bottom of the chamber and are conveyed by screw conveyors and bucket elevators to the separator.

The separator separates:

- Qualified reusable steel shots

- Broken shots and dust

- Sand and impurities

Clean shots return to the blasting wheel automatically, forming a closed abrasive circulation system that reduces shot consumption and improves efficiency.

2.5 Dust Collection System

Dust generated during blasting is collected through air ducts and filtered by cartridge or bag-type dust collectors.

This system keeps the working environment clean and meets environmental protection requirements.

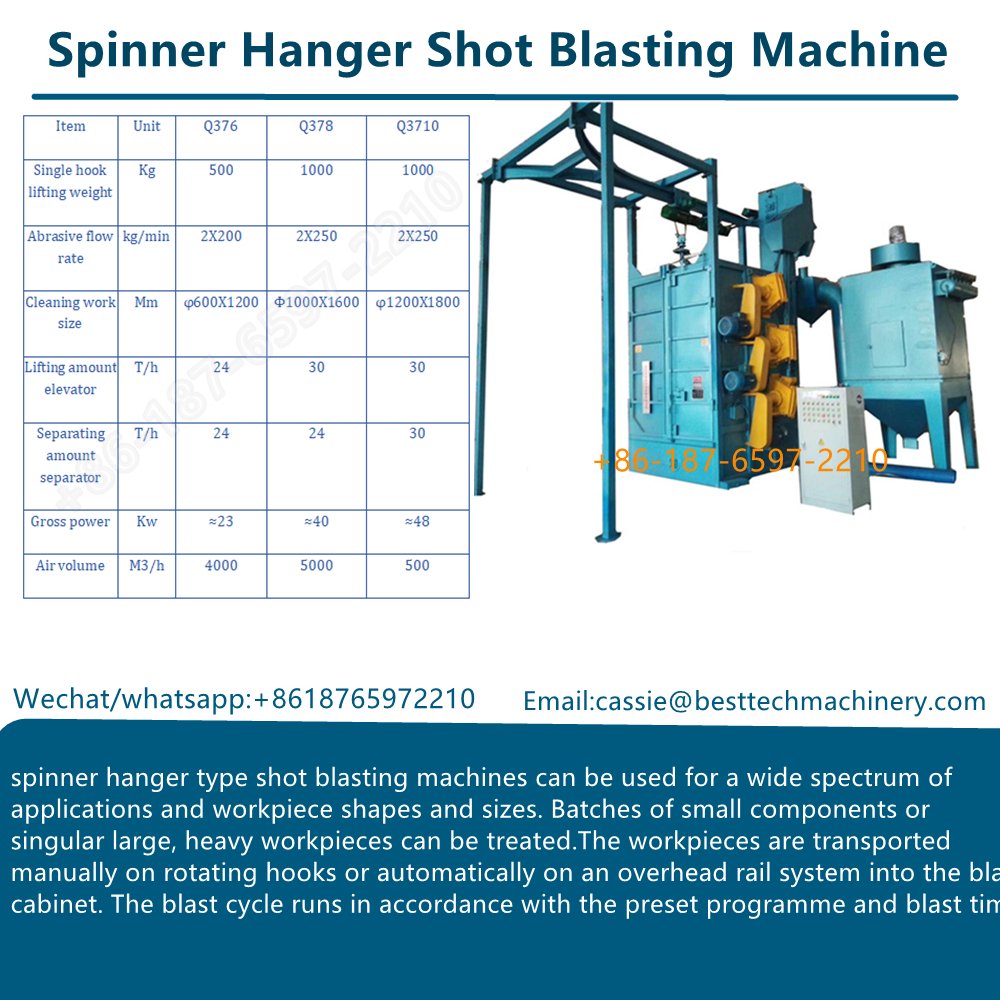

3. Typical Technical Parameters of Hanger Shot Blasting Machine

Below are typical reference parameters. Actual configuration may vary according to customer requirements.

| Item | Parameter Range |

|---|---|

| Maximum workpiece weight | 500 – 5000 kg |

| Hanger rotation speed | 1 – 6 r/min |

| Shot blasting wheel power | 7.5 – 22 kW |

| Shot throwing rate | 120 – 320 kg/min |

| Steel shot size | S230 – S460 |

| Dust collector air volume | 3000 – 12000 m³/h |

| Cleaning efficiency | Sa2.5 (ISO 8501-1) |

| Power supply | 380V / 50Hz (customizable) |

4. Maintenance Methods of Hanger Shot Blasting Machine

Regular maintenance is essential for stable operation and long service life. Engineers usually divide maintenance into daily, periodic, and component-level maintenance.

4.1 Daily Maintenance

- Check blasting wheel noise and vibration before operation

- Observe cleaning effect; uneven blasting may indicate blade wear

- Remove accumulated steel shots around chamber bottom

- Check dust collector pressure difference and filter condition

Daily inspection helps detect potential problems at early stage.

4.2 Shot Blasting Wheel Maintenance

- Regularly inspect blades, impeller, and control cage

- Replace blades in complete sets to keep dynamic balance

- Adjust control cage position to ensure correct blasting angle

Unbalanced blasting wheel will cause strong vibration and shorten bearing life.

4.3 Abrasive and Separator Maintenance

- Maintain correct steel shot size and hardness

- Adjust separator air volume regularly

- Remove broken shots and sand impurities in time

Good separation efficiency directly affects blasting quality and shot consumption.

4.4 Hanger and Transmission System Maintenance

- Check hanger hooks for deformation and cracks

- Ensure load does not exceed rated capacity

- Lubricate bearings, chains, and reducers regularly

Safe hanger operation is critical for large and heavy workpieces.

4.5 Electrical System Maintenance

- Check motor temperature and operating current

- Inspect limit switches, sensors, and safety interlocks

- Keep electrical cabinet clean and dry

Stable electrical control ensures continuous and safe production.

5. Applicable International Standards and References

Hanger shot blasting machines are generally designed and manufactured according to the following standards:

- ISO 8501-1: Surface cleanliness grades of steel substrates

- ISO 11124 / ISO 11125: Metallic abrasive specifications and test methods

- GB/T 8923: Rust grades and preparation grades of steel surfaces

- CE Machinery Directive 2006/42/EC: Safety requirements for machinery

- ISO 12100: Safety of machinery – Risk assessment principles

Compliance with these standards improves equipment reliability and international market acceptance.

6. Application Industries

Hanger shot blasting machines are commonly used in:

- Foundry castings cleaning

- Steel structure surface preparation

- Forged parts descaling

- Welding structure pretreatment

- Heavy machinery components

7.Hanger Shot Blasting Machine Troubleshooting and Maintenance

| No. | Problem Description | Possible Causes | Troubleshooting Methods |

|---|---|---|---|

| 1 | Poor or uneven cleaning effect | Blades worn; control cage position incorrect; hanger rotation speed abnormal; steel shot size unsuitable | Replace blades in full set; adjust control cage angle; check hanger motor and reducer; use correct steel shot size |

| 2 | Blasting dead angle on workpiece | Hanger rotation limited; improper workpiece hanging; blasting wheel layout unreasonable | Increase rotation or swing movement; adjust hanging position; optimize blasting wheel angle |

| 3 | Excessive vibration of blasting wheel | Blade weight imbalance; impeller or control cage worn; steel shot accumulation inside wheel | Replace blades as matched set; inspect impeller and cage; clean wheel housing |

| 4 | Abnormal noise from blasting wheel | Bearing damage; loose fasteners; foreign objects inside wheel | Replace bearings; tighten bolts; stop machine and remove debris |

| 5 | High steel shot consumption | Poor separator efficiency; broken shots not removed; incorrect shot hardness | Adjust separator air volume; clean broken shots regularly; select suitable steel shots |

| 6 | Steel shots not circulating smoothly | Screw conveyor or bucket elevator blocked; excessive shot quantity; moisture in shots | Remove blockage; control shot quantity; keep steel shots dry |

| 7 | Dust leakage from chamber | Door sealing strip worn; dust duct leakage; negative pressure insufficient | Replace sealing rubber; seal air ducts; check dust collector fan |

| 8 | Dust collector suction weak | Filter cartridge blocked; fan rotation wrong; filter damaged | Clean or replace filter; check fan direction; replace damaged filter |

| 9 | Hanger does not rotate | Motor fault; reducer damage; chain or gear worn; overload | Check motor and reducer; replace worn transmission parts; reduce load |

| 10 | Hanger rotation unstable | Motor voltage unstable; control parameter incorrect; mechanical resistance | Stabilize power supply; reset parameters; inspect transmission system |

| 11 | Lifting mechanism failure | Limit switch malfunction; lifting motor fault; mechanical jam | Check limit switches; inspect motor; remove mechanical blockage |

| 12 | Frequent motor overload alarm | Mechanical resistance too high; bearing lubrication insufficient; excessive load | Check moving parts; lubricate bearings; reduce workpiece weight |

| 13 | Electrical system trips frequently | Voltage fluctuation; aging electrical components; wiring loose | Check power supply; replace contactors/relays; tighten wiring |

| 14 | Separator efficiency low | Air volume incorrect; separator internal wear; excessive sand mixed | Adjust air flow; inspect separator wear parts; clean sand impurities |

| 15 | Shot blasting wheel bearing overheating | Poor lubrication; bearing damage; wheel imbalance | Lubricate according to schedule; replace bearing; rebalance wheel |

Conclusion

The hanger shot blasting machine achieves efficient surface cleaning through high-speed centrifugal blasting combined with hanger rotation. From an engineering perspective, proper understanding of working principle, correct parameter selection, and systematic maintenance are key factors for long-term stable operation.

By following standardized maintenance procedures and international standards, users can reduce downtime, lower operating costs, and achieve consistent surface treatment quality.