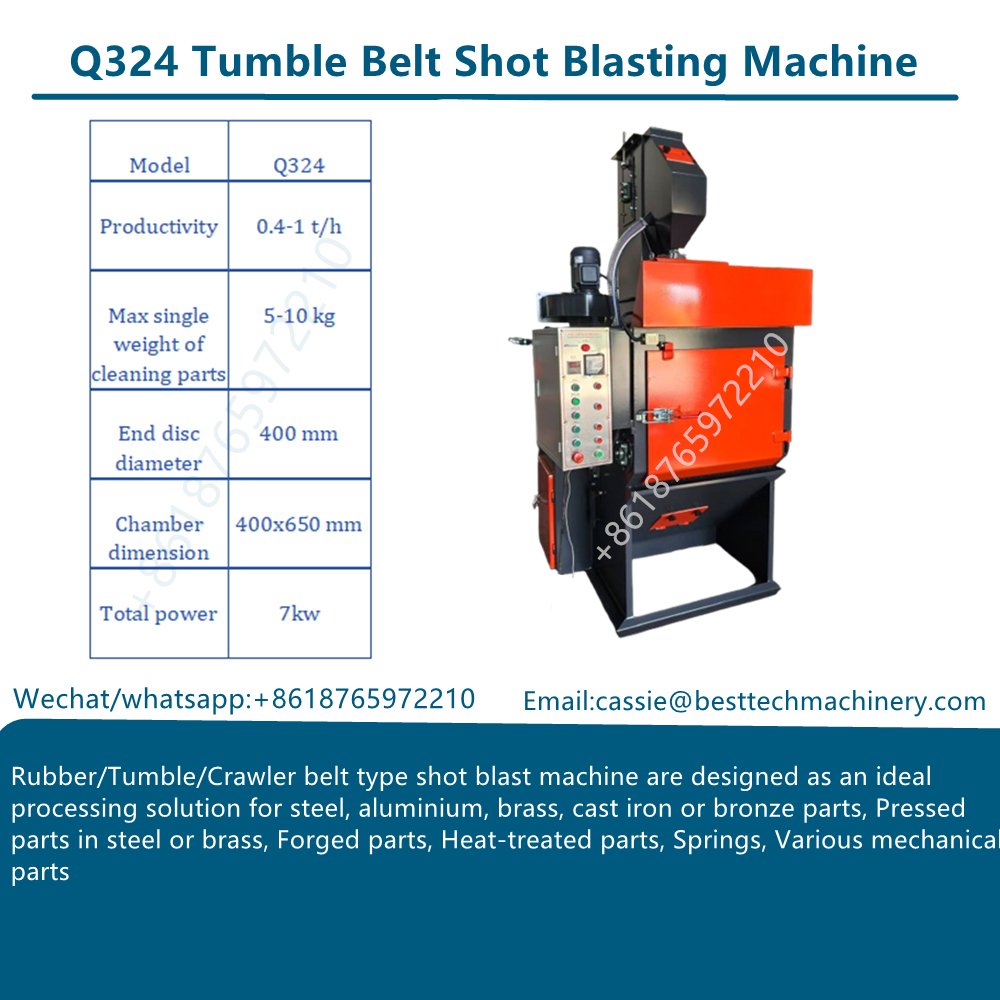

A Tumblast Shot Blast Machine is a highly efficient surface preparation system designed for cleaning, descaling, and finishing a wide variety of small to medium-sized workpieces. This machine is widely used in the foundry, automotive, forging, and heat-treatment industries where mass production and consistent quality are essential.

What Is a Tumblast Shot Blast Machine?

The Tumblast Shot Blast Machine operates on a batch principle. Workpieces are loaded into a robust tumbling drum or belt conveyor. As the drum rotates, the parts tumble over one another, ensuring that every surface is evenly exposed to the high-velocity abrasive stream generated by blast wheels. This tumbling action guarantees uniform cleaning, even for complex-shaped components.

Key Features

- Continuous Tumbling Action – Ensures thorough and even cleaning of all surfaces.

- High Productivity – Capable of processing large volumes of parts in each batch cycle.

- Versatility – Suitable for castings, forgings, springs, and other small to medium metal parts.

- Durability – Designed with wear-resistant materials to handle abrasive impacts and extend machine life.

- Automation Options – Available with automatic loading/unloading systems for streamlined operations.

Applications

Tumblast shot blast machines are ideal for:

- Casting and Foundry Industry – Removal of sand, scale, and residues from castings.

- Forging Industry – Descaling and surface cleaning of forged components.

- Automotive Industry – Cleaning engine parts, gears, springs, and other precision components.

- Heat Treatment Plants – Removing oxide layers and scale from heat-treated workpieces.

Benefits of Using Tumblast Shot Blast Machines

- Cost-Effective Cleaning – Processes large batches with reduced labor costs.

- Consistent Quality – Uniform surface finishing across all parts.

- Space-Saving Design – Compact footprint compared to other blasting systems.

- Eco-Friendly – Recycles abrasive media, reducing waste and operating costs.

- Adaptability – Handles a wide range of materials and part geometries.

Why Choose a Tumblast Shot Blast Machine?

In industries such as foundry, automotive, and forging, efficient and reliable surface preparation is essential. Among the different shot blasting technologies available, the Tumblast Shot Blast Machine stands out as a preferred choice for mass production of small to medium-sized components. But why should you choose a tumblast machine over other blasting systems?

1. High Productivity and Efficiency

The tumblast design allows parts to tumble continuously during blasting. This ensures that every surface is evenly cleaned in one cycle, even for complex-shaped parts. Large batches of workpieces can be processed quickly, saving time and labor while maintaining consistent quality.

2. Uniform and Thorough Cleaning

The continuous tumbling action exposes all sides of each component to the abrasive stream. Unlike static blasting methods, tumblast machines eliminate “blind spots,” guaranteeing uniform descaling, deburring, or surface finishing across every workpiece.

3. Space-Saving and Cost-Effective

Compared to other high-capacity blasting systems, tumblast machines offer a compact design that saves valuable floor space. They also recycle abrasive media, reducing consumption and operational costs, making them a budget-friendly solution for long-term use.

4. Versatility Across Industries

Tumblast shot blast machines can handle a wide range of materials and part geometries. They are widely applied in:

- Foundries – Removing sand, rust, and scale from castings.

- Forging Plants – Cleaning forgings before machining or coating.

- Automotive Industry – Treating gears, springs, and engine components.

- Heat Treatment Facilities – Removing scale and oxide layers after processing.

5. Durability and Reliability

Built with wear-resistant materials, tumblast shot blast machines are engineered to withstand continuous heavy-duty operation. Their robust design ensures long service life, reducing downtime and maintenance costs.

6. Automation Options

Modern tumblast machines can be integrated with automatic loading/unloading systems, conveyors, and dust collectors. This reduces manual handling, increases safety, and ensures a smooth, automated workflow.

Choosing a Tumblast Shot Blast Machine means investing in a surface preparation system that offers high efficiency, uniform results, cost savings, and long-term reliability. For industries that demand consistent, large-volume cleaning of metal components, the tumblast shot blast machine is a smart and proven solution.

Conclusion

The Tumblast Shot Blast Machine is a powerful and reliable solution for industries requiring efficient cleaning and surface finishing of bulk parts. Its combination of high throughput, consistent results, and low operational cost makes it an indispensable choice in modern manufacturing environments.