On the shop floor, we deal with parts that come in covered with rust, scale, or old paint. Cleaning them by hand is slow, inconsistent, and eats up labor hours. That’s why the tumble belt shot blasting machine is a real workhorse for us.

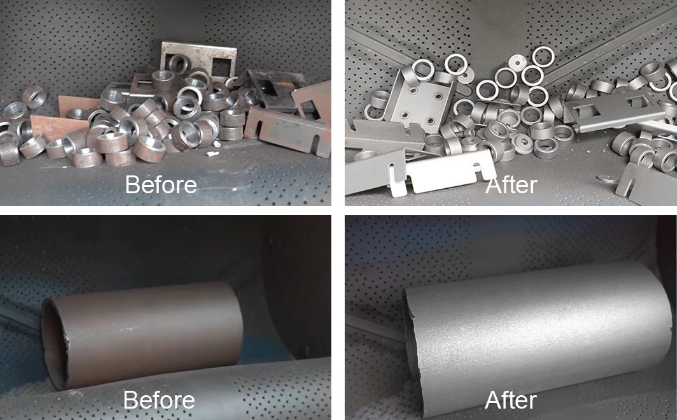

Tumble shot blasting machine is an industrial surface cleaning and finishing machine used to remove rust, paint, scale, sand, or other surface contaminants from metal parts. It’s designed mainly for small to medium-sized workpieces that can tumble over each other without damage.

How It Works

Parts are loaded onto a rubber belt. As the belt turns, the parts tumble over each other while the blast wheels fire abrasive shots at them. Because the parts keep rolling, every side gets hit. The result: clean, even surfaces without us having to reposition anything.

Why We Use It

- Reliable cleaning – Rust, paint, and scale are stripped off fast and evenly.

- Batch processing – Just load the batch, hit start, and let the machine do the hard work.

- Better adhesion – After blasting, the surface is roughened enough so new paint or coating sticks firmly.

- Saves labor – No endless grinding or sanding, freeing up the crew for other jobs.

- Durable and cost-efficient – Media is recycled in the system, and the machine can handle heavy daily use.

Where It Helps Most

- Automotive components (wheels, brackets, housings).

- Small and medium castings after shakeout.

- Forgings and stamped parts with surface scale.

- General workshop parts before painting or powder coating.

Operating Steps for Tumble Belt Shot Blasting Machine

On the shop floor, we run the tumble belt shot blasting machine almost every day. The process is straightforward, but it needs to be followed step by step to keep things safe and efficient. Here’s how we do it:

1. Pre-Check Before Starting

- Inspect the machine for any loose bolts, abnormal sounds, or wear on the belt.

- Make sure the blast wheels, liners, and abrasive supply system are in good condition.

- Check the dust collector — ensure filters and ducts are clear.

- Verify that abrasive level in the hopper is enough for the cycle.

2. Loading Parts

- Place the workpieces evenly on the rubber belt, not more than the rated load.

- Avoid sharp or oversized pieces that could cut or damage the belt.

- Make sure parts can tumble freely — don’t overload or stack too high.

3. Starting the Machine

- Close the door and lock it properly.

- Start the dust collector.

- Start the blast wheel motors.

- Start the belt drive so the parts begin tumbling.

- Open the abrasive valve — blasting begins.

4. Blasting Operation

- Let the machine run for the preset cycle time (depends on rust/paint level).

- Watch for unusual noises or imbalance — stop immediately if something sounds off.

- The abrasive will circulate automatically through the reclaim system.

5. Unloading Parts

- After blasting, close the abrasive valve.

- Stop blast wheels and then stop the belt.

- Open the door carefully once everything has stopped.

- Unload the cleaned parts with care — avoid hitting the belt.

6. After-Use Checks

- Run the dust collector for a few more minutes to clear the chamber.

- Check the machine interior for wear and collected debris.

- Top up abrasive if the level is low.

- Shut down power after confirming everything is normal.

Notes from the Floor

- Always wear protective gear (ear protection, gloves, dust mask).

- Never open the door while the blast wheels are running.

- Keep abrasive dry and clean — moisture will block the system.

- Stick to the rated capacity — overloading causes poor cleaning and damages the belt.

Final Word

For everyday rust and paint removal, the tumble belt shot blasting machine keeps production moving. It cleans multiple parts at once, does it faster than manual methods, and leaves the surface ready for finishing. On the shop floor, it’s one of those machines you don’t want to be without.