A Tumble Blast Machine is a highly effective surface preparation and cleaning equipment widely used in industries such as foundry, automotive, aerospace, metalworking, and construction. This machine is specifically designed for cleaning, deburring, descaling, and surface finishing of small to medium-sized workpieces that can withstand tumbling.

What is a Tumble Blast Machine?

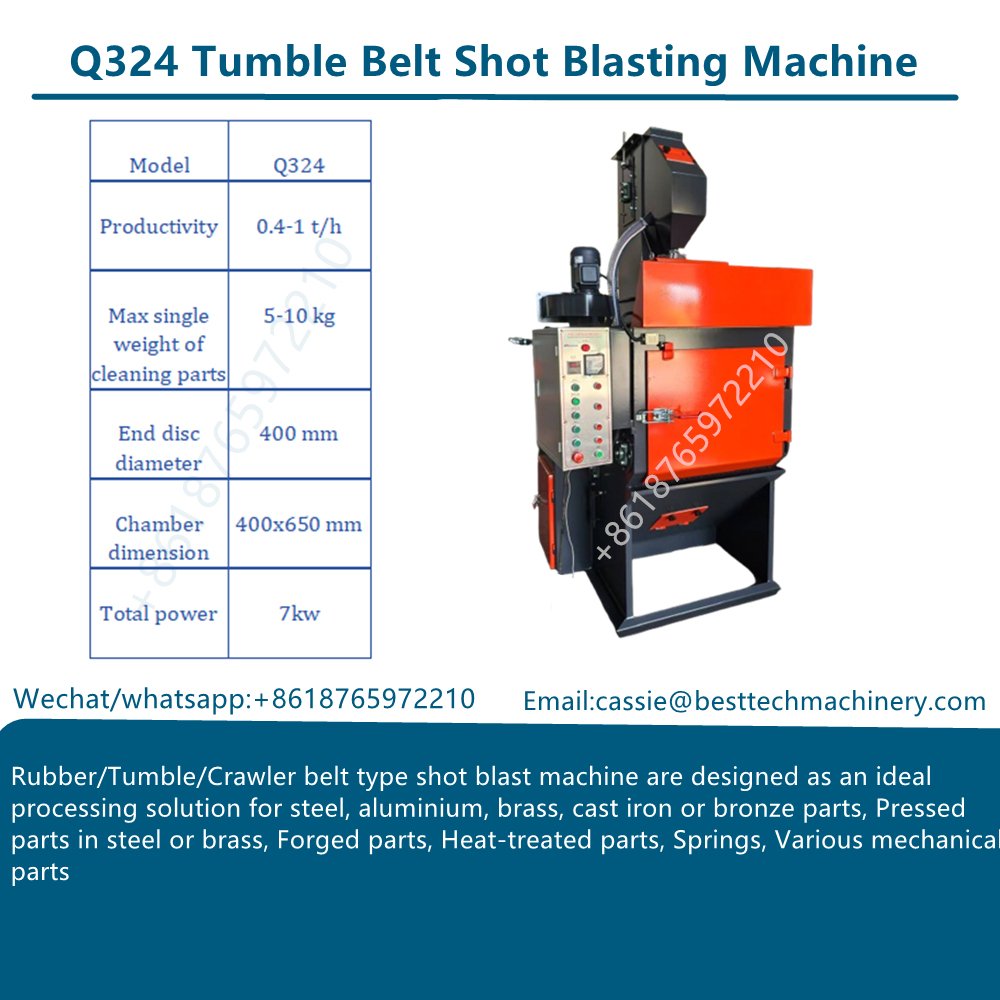

A Tumble Blast Machine is a type of shot blasting equipment designed for cleaning, descaling, deburring, and surface finishing of small to medium-sized workpieces. It operates on a batch-processing principle, where components are loaded into a rotating drum or belt and continuously tumbled while being blasted with high-speed abrasive media.

How It Works

The tumble blast machine operates on a batch-processing principle. Workpieces are loaded into a rotating drum or rubber/steel belt conveyor inside the blasting chamber. As the drum rotates, the parts tumble over each other while high-speed abrasive media, propelled by blast wheels, strike the surfaces from multiple angles. This simultaneous tumbling and blasting action ensures thorough cleaning and uniform surface coverage.

Key Features

- Continuous Tumbling Action – Ensures all sides of the workpiece are exposed for even cleaning.

- Efficient Blast Wheel Technology – Delivers high blasting power with low energy consumption.

- Compact & Durable Design – Occupies minimal floor space while providing long service life.

- Automatic Dust Collection System – Maintains a clean working environment and extends machine lifespan.

- Versatile Media Compatibility – Works with steel shot, grit, or other abrasive materials depending on application needs.

Applications

Tumble blast machines are suitable for:

- Rust and Scale Removal from forged or cast parts.

- Deburring of machined components.

- Surface Preparation before painting, coating, or galvanizing.

- Cleaning of Heat-Treated Parts to remove oxidation and residues.

Advantages of Tumble Blast Machines

- High Productivity – Can process multiple parts simultaneously in each batch.

- Consistent Results – Uniform blasting ensures stable quality from batch to batch.

- Cost-Effective Operation – Low maintenance and reduced abrasive consumption.

- Automation Options – Can be integrated into production lines for semi- or fully-automatic operation.

Why Choose a Tumble Blast Machine?

In industrial manufacturing, the quality of surface preparation directly impacts the durability and appearance of the final product. A Tumble Blast Machine offers a fast, reliable, and cost-effective solution for cleaning, deburring, descaling, and finishing small to medium-sized workpieces. Here are the main reasons why it stands out as a preferred choice for many industries.

1. All-Around Cleaning Efficiency

The continuous tumbling action inside the rotating drum or belt ensures that every surface of each workpiece is exposed to the blast stream. This 360° coverage results in consistent and uniform cleaning, even for complex shapes and hard-to-reach areas.

2. High Productivity for Batch Processing

Tumble blast machines are designed to handle multiple components in each cycle, making them ideal for batch production. This saves both time and labor compared to manual cleaning methods.

3. Versatility Across Applications

Whether it’s removing rust from forgings, cleaning sand from castings, deburring machined parts, or preparing surfaces for coating, a tumble blast machine can handle a wide range of tasks with ease.

4. Cost-Effective Operation

With efficient blast wheel technology and optimized abrasive recycling systems, tumble blast machines minimize abrasive consumption and maintenance costs. This translates into lower operating expenses over time.

5. Durable and Reliable Construction

Built with heavy-duty materials and designed for continuous operation, these machines offer long service life and dependable performance even in demanding industrial environments.

6. Cleaner and Safer Working Environment

Integrated dust collection systems ensure that blasting operations generate minimal airborne particles, protecting both workers and the workspace.

Choosing a Tumble Blast Machine means investing in a robust, versatile, and efficient surface preparation solution. Its ability to deliver uniform results, process multiple parts in one cycle, and reduce operational costs makes it an essential asset for industries such as foundry, automotive, aerospace, and metal fabrication. With the right tumble blast machine, manufacturers can achieve higher productivity, better quality, and greater cost savings.

Conclusion

The Tumble Blast Machine is a reliable and efficient solution for mass surface cleaning and preparation of small and medium-sized workpieces. Its ability to handle a variety of materials and shapes makes it a valuable asset for any industrial manufacturing process. By combining high-speed abrasive blasting with continuous tumbling, it delivers consistent, high-quality results with minimal labor input.