In the field of surface preparation and finishing, the tumble blaster has emerged as a highly efficient solution, especially for cleaning and descaling small to medium-sized metal parts in bulk. Whether it’s removing rust, scale, burrs, or preparing surfaces for painting or coating, the tumble blaster offers consistent, automated results that improve productivity and quality.

The Significance of Metal Surface Treatment and How the Tumble Blaster Enhances Efficiency

In modern manufacturing, metal surface treatment plays a crucial role in ensuring the performance, durability, and appearance of metal components. Whether preparing parts for painting, improving corrosion resistance, or removing imperfections, surface treatment is a key step in the production process. Among the various surface preparation methods, the tumble blaster stands out as a powerful tool that enhances efficiency and quality in metal treatment operations.

Why Metal Surface Treatment Matters

Metal components are often exposed to harsh environments, mechanical wear, and chemical corrosion. Without proper surface treatment, these parts can fail prematurely or underperform in their intended applications. Surface treatment provides several essential benefits:

- Corrosion Protection: Removes rust and prepares the surface for protective coatings like paint, powder coat, or plating.

- Improved Adhesion: Enhances bonding between the metal surface and subsequent coatings or adhesives.

- Aesthetic Enhancement: Achieves a clean, uniform appearance by removing scales, burrs, and other surface flaws.

- Functional Performance: Improves fatigue strength and resistance to mechanical wear.

The Role of Tumble Blasting in Surface Treatment

A tumble blaster, or tumble shot blasting machine, automates and streamlines the surface treatment process for small to medium-sized parts. It uses a rotating drum or belt to gently tumble metal parts while blasting them with high-speed abrasive media. This combination delivers thorough and uniform cleaning on all surfaces of the components.

How the Tumble Blaster Enhances Metal Surface Treatment Efficiency

- Batch Processing for High Volume

Tumble blasters can handle large quantities of small parts in a single cycle, making them ideal for mass production. This reduces downtime and manual labor, significantly increasing throughput. - Consistent Surface Quality

The tumbling motion ensures that every part is exposed evenly to the blasting media, resulting in a uniform finish that meets quality standards across every batch. - Reduced Manual Intervention

The machine’s automated operation — from loading to blasting to unloading — minimizes the need for operator involvement and reduces the risk of human error. - Durable and Cost-Efficient

Built for long-term operation, tumble blasters use wear-resistant materials and can operate continuously with low maintenance requirements, offering excellent return on investment. - Versatile Applications

Tumble blasters are suitable for removing rust, scale, sand, paint, and burrs, as well as for surface texturing and preparation before coating or bonding.

Ideal for a Wide Range of Industries

Industries such as automotive, foundry, metal fabrication, hardware manufacturing, and aerospace benefit greatly from tumble blasting due to its ability to handle complex shapes and high production volumes efficiently.

Metal surface treatment is essential to ensuring the reliability and performance of manufactured components. The tumble blaster offers a fast, consistent, and cost-effective method for treating metal surfaces, especially when handling high volumes of small parts. By integrating tumble blasting into production lines, manufacturers can enhance product quality, extend service life, and improve overall process efficiency.

What is a Tumble Blaster?

A tumble blaster, also known as a tumble shot blasting machine, is a type of shot blasting equipment designed to handle large volumes of small parts by rotating them in a barrel or rubber belt drum while blasting media (usually steel shot or grit) is propelled at high speed onto the surfaces. This process allows for even and thorough treatment of all parts within a single cycle.

Key Features

- Rotating Drum or Belt: The tumble movement ensures that all surfaces of the parts are exposed to the blasting media.

- Automated Operation: The machine operates in cycles, loading, blasting, and unloading without continuous manual intervention.

- High Efficiency: Multiple parts can be processed simultaneously, reducing time and cost.

- Durable Design: Made from wear-resistant materials to withstand continuous exposure to abrasive media.

Applications

Tumble blasters are widely used in industries such as:

- Automotive: Cleaning engine parts, fasteners, and gear components.

- Foundry: Desanding and deburring castings.

- Forging: Removing scale from forged items.

- Metalworking: Surface preparation before coating or painting.

Advantages of Using Tumble Blasters

- Consistent Results: Uniform exposure to blasting ensures a consistent finish across all parts.

- Cost-Effective: Suitable for batch processing, reducing labor and energy costs.

- Improved Surface Quality: Enhances adhesion of coatings, extending product lifespan.

- Compact and Versatile: Requires minimal floor space and can handle a wide range of part sizes and shapes.

Choosing the Right Tumble Blaster

When selecting a tumble blaster, consider the following:

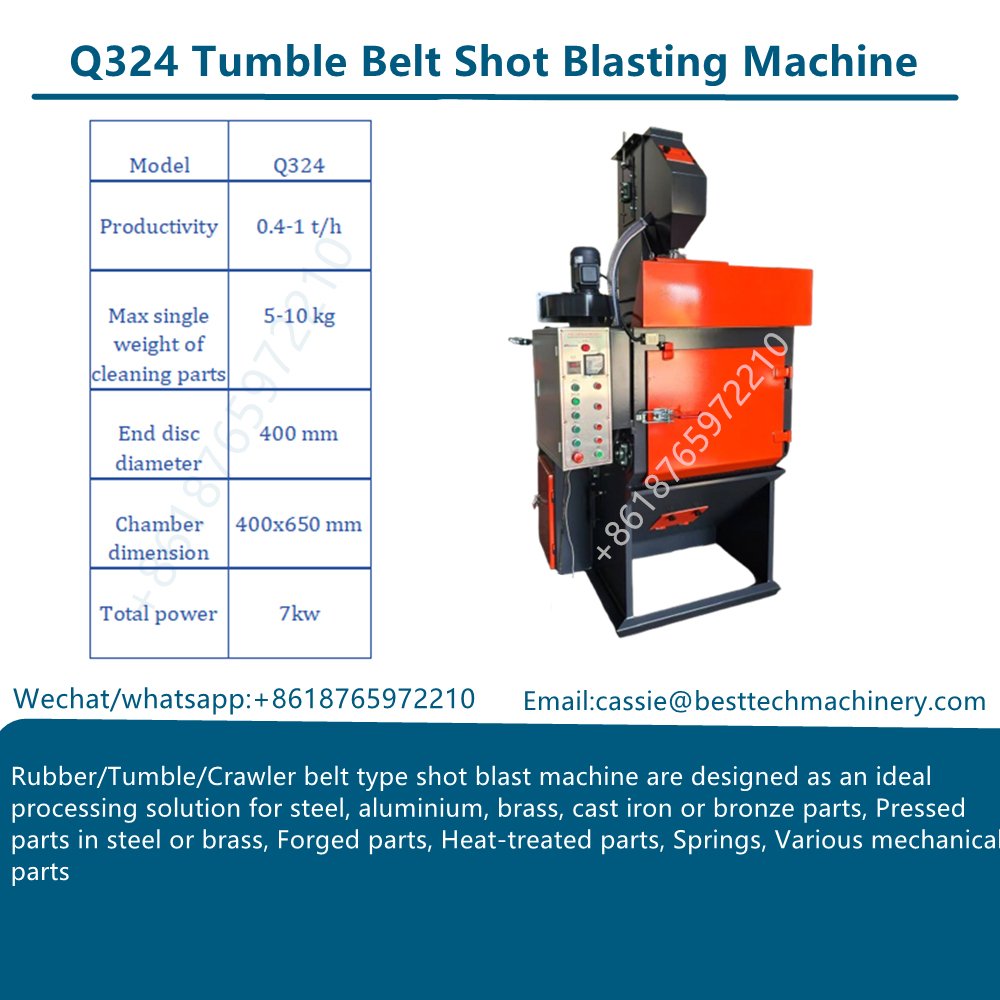

- Part Size and Weight: Ensure the drum size and weight capacity match your parts.

- Production Volume: Choose a machine that can handle your daily output efficiently.

- Abrasive Type: Match the media to the material and finish requirements of your parts.

- Automation Needs: Some models offer loading/unloading automation to further boost productivity.

Why Tumble Blasters Are Widely Used in Modern Manufacturing

In the field of metal surface preparation, tumble blasters have gained widespread popularity across a variety of industries. Their unique combination of efficiency, automation, and versatility makes them an ideal solution for cleaning, deburring, descaling, and preparing small to medium-sized metal parts. But what exactly makes the tumble blaster such a preferred choice in industrial applications?

1. Efficient Batch Processing

Tumble blasters are designed to process multiple parts simultaneously. This makes them exceptionally efficient for handling high production volumes. The tumbling motion allows parts to be cleaned on all sides without manual repositioning, ensuring consistent and thorough treatment throughout the batch.

2. Uniform Surface Finish

Thanks to the continuous tumbling action and controlled shot blasting, tumble blasters provide a uniform surface finish on all components. This consistency is critical in industries where parts need to meet strict quality standards or require surface preparation for painting, coating, or plating.

3. Automated and Labor-Saving

Tumble blasters offer automated operation, reducing the need for manual labor. Operators can simply load the parts, start the machine, and allow the system to complete the blasting cycle. This automation not only boosts productivity but also minimizes the risk of human error and workplace injuries.

4. Compact Design and Small Footprint

Tumble blasters, especially rubber belt or drum types, are compact in size, making them ideal for workshops with limited space. Despite their small footprint, they can process a large number of parts efficiently, which enhances space utilization.

5. Versatility Across Industries

Tumble blasters are widely used in:

- Automotive: for cleaning engine components, brake parts, and fasteners.

- Foundries: for desanding and deburring castings.

- Forging: for removing oxide layers after heat treatment.

- General metalworking: for surface roughening and preparation before coating.

Their ability to handle different materials—such as steel, iron, aluminum, brass—makes them a versatile choice for many manufacturers.

6. Durability and Low Maintenance

Modern tumble blasters are built with wear-resistant materials and durable construction, ensuring a long service life even under heavy use. Additionally, maintenance requirements are relatively low, which reduces downtime and maintenance costs.

7. Cost-Effectiveness

Because tumble blasters can process many parts at once and require minimal human supervision, they reduce operational costs significantly. The combination of high productivity and low labor input makes them one of the most cost-effective surface treatment solutions available.

The tumble blaster’s popularity is no accident. It offers a powerful combination of efficiency, consistency, automation, and cost savings. As industries demand faster production and higher quality standards, the tumble blaster continues to prove its value in metal surface treatment applications. Its widespread use across various sectors highlights its role as a reliable and economical solution for modern manufacturing challenges.

Conclusion

The tumble blaster is a reliable and efficient tool for surface treatment of metal parts in large quantities. Its automated process, durable construction, and uniform cleaning results make it an essential part of modern manufacturing lines. For companies looking to improve their surface preparation process while reducing costs and manual labor, investing in a tumble blaster is a smart choice.