In the brass casting industry, achieving a clean, smooth, and defect-free surface is crucial for both appearance and functionality. A tumble shot blast machine provides an efficient, reliable, and cost-effective solution for surface treatment of brass castings. Its unique design and high-performance blasting process make it a preferred choice for foundries and manufacturers seeking to enhance product quality.

What is a Tumble Shot Blast Machine?

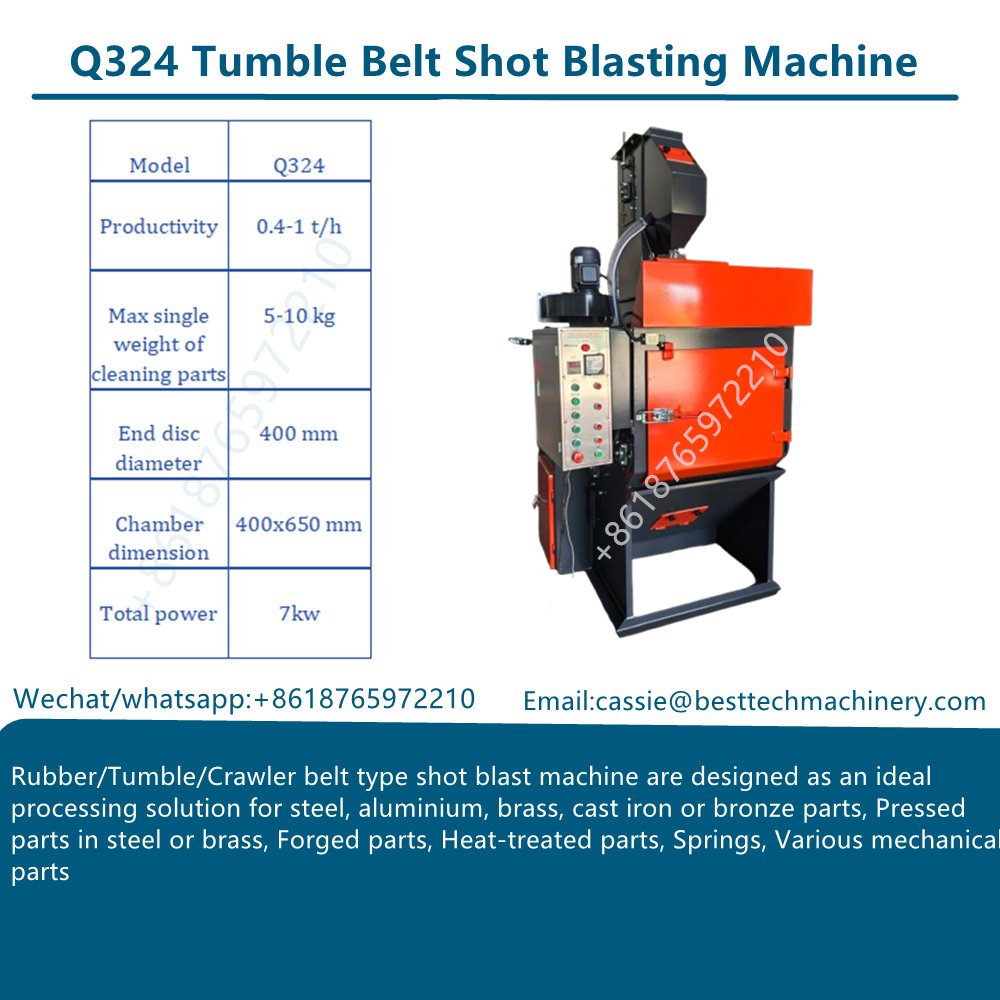

A tumble shot blast machine is a type of abrasive blasting equipment designed for cleaning, surface preparation, and finishing of small to medium-sized metal parts. It is widely used in foundries, automotive, aerospace, and general metalworking industries where batch processing and efficient surface treatment are required.

How It Works

The machine consists of a blasting chamber with a rubber or steel belt that forms a continuous loop. Workpieces are loaded into the chamber, where they tumble over each other while a high-speed blast wheel projects abrasive media onto them. This simultaneous tumbling and blasting action ensures all sides of the parts are exposed, resulting in uniform cleaning and finishing.

Key Features

- Batch Processing: Suitable for processing multiple parts at once.

- Uniform Coverage: The tumbling action guarantees even exposure of surfaces.

- Versatility: Works with different types of abrasives and part materials.

- Durability: Built to handle heavy-duty use in industrial environments.

Benefits

- High Efficiency: Processes a large number of parts in each cycle.

- Consistent Results: Provides uniform surface quality across all workpieces.

- Labor Saving: Reduces or eliminates manual cleaning needs.

- Compact Design: Requires less floor space compared to other blasting systems.

Why Brass Castings Need Surface Treatment

Brass castings often come out of the mold with sand, scale, and oxidation layers that must be removed before further processing. Without proper cleaning, these imperfections can affect machining, plating, or coating quality. Surface treatment is also essential to improve dimensional accuracy and extend the lifespan of the final product.

How Tumble Shot Blast Machines Work

The tumble shot blast machine is designed for batch processing of small and medium-sized parts. Brass castings are loaded into a rubber or steel belt chamber where they tumble continuously. As the workpieces rotate, a high-speed blast wheel propels abrasive media onto their surfaces. This combination of tumbling and blasting ensures every side of the brass casting is evenly cleaned and polished.

Key Advantages for Brass Castings

- High Efficiency: Processes multiple brass castings simultaneously, saving time and labor.

- Uniform Cleaning: Tumbling action guarantees all surfaces are treated evenly.

- Enhanced Surface Quality: Removes sand, scale, and oxidation, improving adhesion for coatings or plating.

- Durability: Designed to withstand the abrasive cleaning of heavy and complex-shaped brass parts.

- Cost-Effective: Reduces manual cleaning requirements while increasing throughput.

Applications in Brass Casting Industry

- Removing sand and oxide layers from raw castings.

- Preparing surfaces for electroplating, painting, or powder coating.

- Improving dimensional accuracy for precision brass components.

- Cleaning decorative brass items where appearance is critical.

The tumble shot blast machine is an ideal surface treatment solution for brass castings. By combining efficient cleaning with consistent quality, it helps manufacturers achieve higher productivity and superior finishes. For foundries and metalworking plants, adopting this technology ensures long-term cost savings and improved competitiveness in the market.

Conclusion

In summary, a tumble shot blast machine is an essential tool for industries that require efficient, reliable, and cost-effective cleaning and surface treatment of small and medium-sized components. Its combination of tumbling and blasting makes it a highly effective solution for achieving consistent results in mass production environments.