Tumble shot blast machines are essential equipment in modern manufacturing, especially in foundries, forging plants, and metalworking industries. Designed to clean and treat the surface of metal components, these machines use a tumbling motion combined with high-speed abrasive blasting to remove scale, rust, sand, and other surface contaminants.

The Development History of Tumble Shot Blast Machines

Tumble shot blast machines have become an indispensable part of surface treatment processes in foundries, forging shops, and metalworking industries. Their development over time reflects broader advances in manufacturing automation, materials engineering, and surface preparation technology. Let’s take a look at the evolution of tumble shot blast machines—from their origins to today’s modern systems.

1. Early Origins (Mid-20th Century)

The concept of using abrasive blasting to clean metal surfaces dates back to the early 20th century. However, the tumble shot blasting process—specifically designed for batch processing of small to medium parts—emerged after World War II, as manufacturing rapidly expanded.

These early machines featured simple, manually operated drums and single blast wheels. Parts were manually loaded into steel or rubber-lined barrels that rotated while steel shot was thrown by an impeller. This provided a consistent way to remove scale, sand, and rust from rough metal parts.

2. Industrialization and Standardization (1960s–1980s)

During the post-war industrial boom, tumble shot blast machines became increasingly popular in foundries and forging plants due to their ability to clean large volumes of parts efficiently.

Key developments during this period included:

- Standardized machine models like Q324 and Q326.

- Rubber belt barrels that allowed gentle handling of delicate parts.

- Integrated dust collectors to improve workplace safety and air quality.

- Improved blast wheels with higher efficiency and wear resistance.

These changes made the machines more durable, easier to maintain, and suitable for various materials.

3. Automation and Efficiency (1990s–2000s)

With the rise of automation and lean manufacturing, the design of tumble shot blast machines also evolved. Key improvements included:

- PLC-based control systems for automatic cycle control.

- Hydraulic or pneumatic loading and unloading systems to reduce labor.

- Abrasive recycling systems to minimize media consumption.

- Noise and vibration reduction for better operator comfort.

During this time, manufacturers began customizing machines for specific industries, such as automotive parts cleaning or aerospace hardware finishing.

4. Modern Innovations (2010s–Present)

Today’s tumble shot blasting machines incorporate advanced technologies that enhance performance, energy efficiency, and digital monitoring. Some modern advancements include:

- IoT integration and smart controls, allowing real-time monitoring and predictive maintenance.

- Energy-saving motors and blast wheels with optimized design.

- Modular machine architecture for flexible installation and customization.

- Eco-friendly dust collection systems with low emissions.

In addition, machines now support quick changeovers, enabling more agile production in job shops and mixed-product manufacturing.

5. Future Trends

The future of tumble shot blasting machines is likely to emphasize:

- AI-powered process optimization.

- Fully automated production cells with robotic part handling.

- Advanced wear-resistant materials for longer machine life.

- Sustainable manufacturing, with reduced power and abrasive usage.

From their humble beginnings as manual batch cleaners to today’s intelligent, high-efficiency systems, tumble shot blast machines have undergone significant evolution. Their development mirrors the progress of the manufacturing industry as a whole—driven by the need for productivity, quality, and innovation. As industrial requirements grow, these machines will continue to adapt, providing reliable surface preparation solutions for decades to come.

What is a Tumble Shot Blast Machine?

A tumble shot blast machine is a highly efficient surface preparation tool designed to clean, descale, deburr, and remove sand or rust from bulk metal components. It operates by tumbling parts in a rotating drum while blasting them with high-speed steel shot or grit, ensuring uniform exposure to the abrasive media.

How Tumble Shot Blast Machines Work

Tumble shot blasting machines operate with a rubber or steel belt drum, which continuously rotates to tumble the parts inside. As the parts tumble, blast wheels throw steel shot or grit at high velocity onto the components. This simultaneous tumbling and blasting action ensures that all surfaces of the parts are evenly exposed to the abrasive media.

The process is fully enclosed and often includes a dust collector to keep the environment clean and safe.

Key Features and Advantages

- Uniform Cleaning: The tumbling motion allows for consistent cleaning of all surfaces, including complex geometries and hard-to-reach areas.

- Batch Processing: Ideal for bulk processing of small to medium-sized parts, increasing productivity.

- Durable Design: Built to handle heavy-duty use with robust materials and wear-resistant components.

- Automated Operation: Many models come with automatic loading, unloading, and abrasive recycling systems.

- Cost-Effective: Efficient use of abrasives and energy helps reduce operational costs.

Ideal for:

- Small to medium-sized castings, forgings, and heat-treated parts.

- Batch processing of rugged, irregularly shaped items.

- Ferrous and non-ferrous materials.

Applications

Tumble shot blast machines are widely used in various industries, including:

- Foundry industry: Cleaning castings and removing molding sand.

- Forging workshops: Removing scale and preparing surfaces for finishing.

- Heat treatment plants: Cleaning heat-treated components.

- Automotive industry: Preparing metal parts for coating or assembly.

- General metalworking: Rust and paint removal from fabricated parts.

Typical Workpieces

- Small castings and forgings

- Nuts, bolts, gears, and springs

- Chain links and structural components

- Heat-treated parts and hardware

Common Models

Different models are available to meet varying production requirements. Common types include:

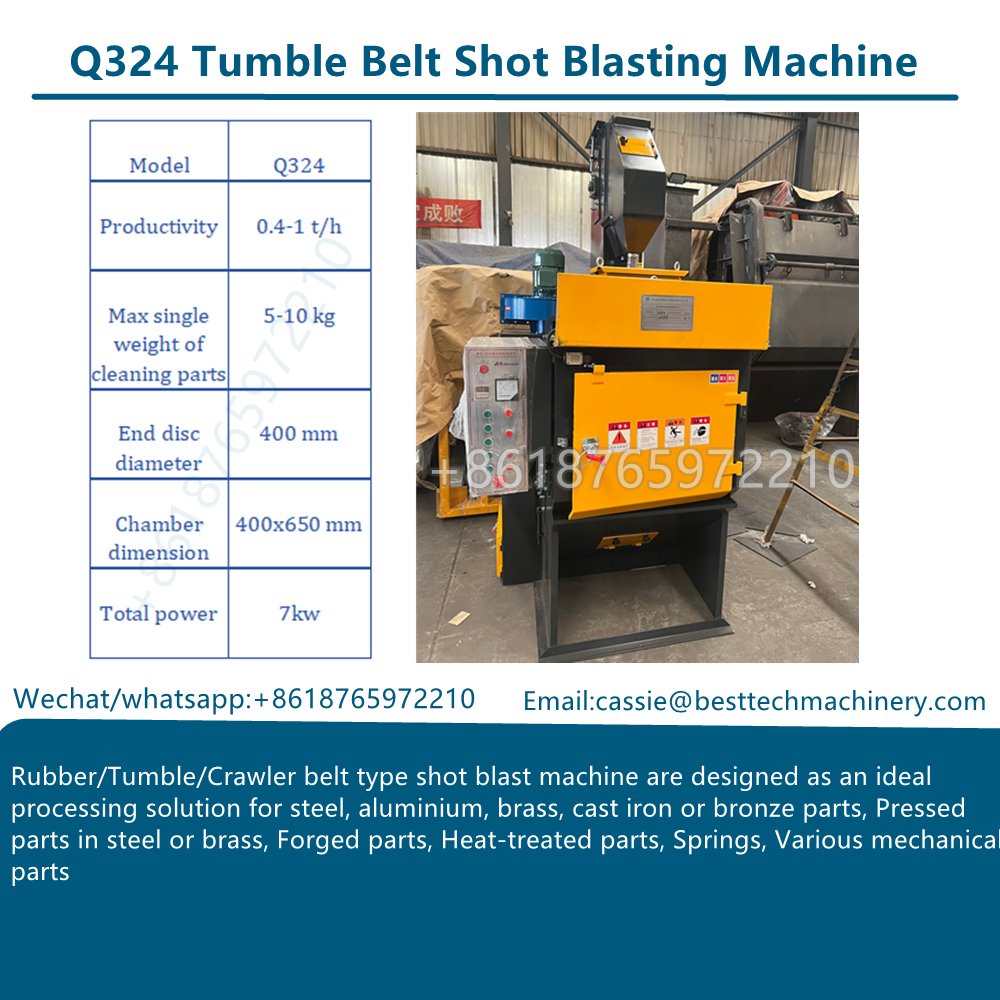

- Q324

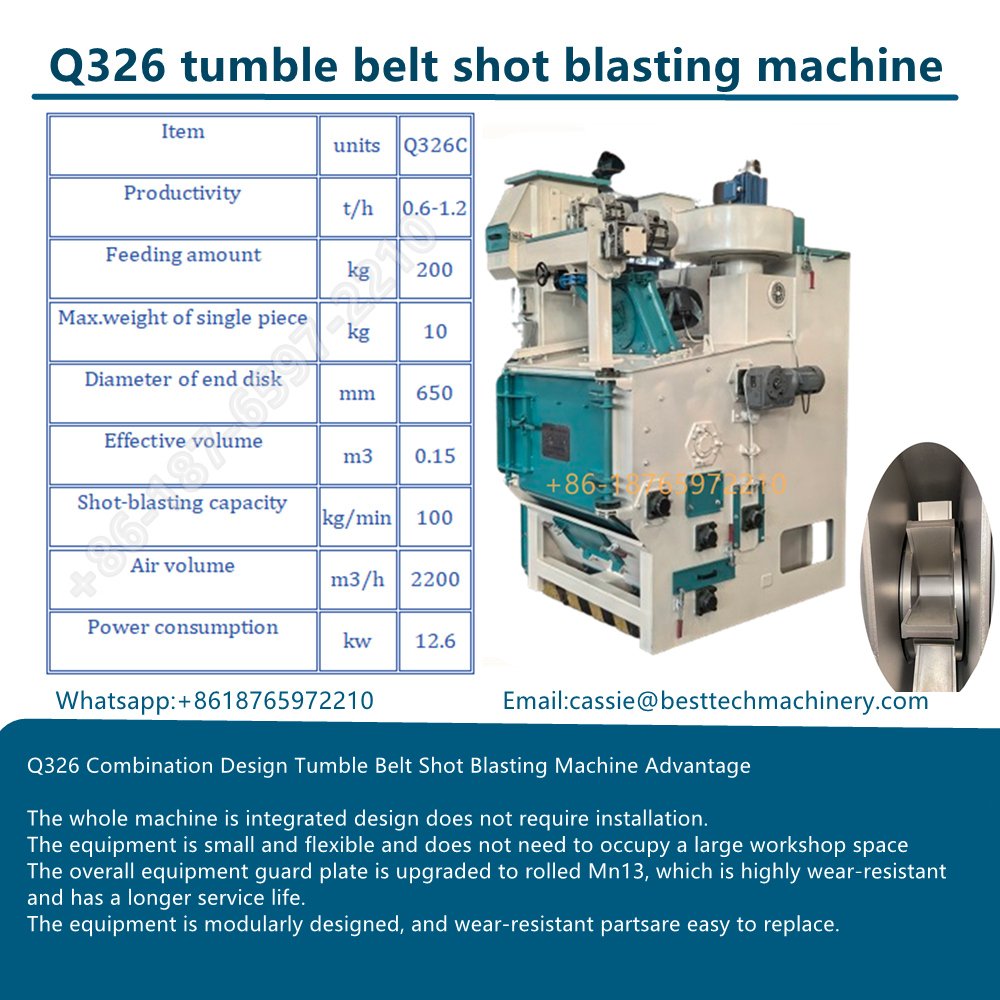

- Q326

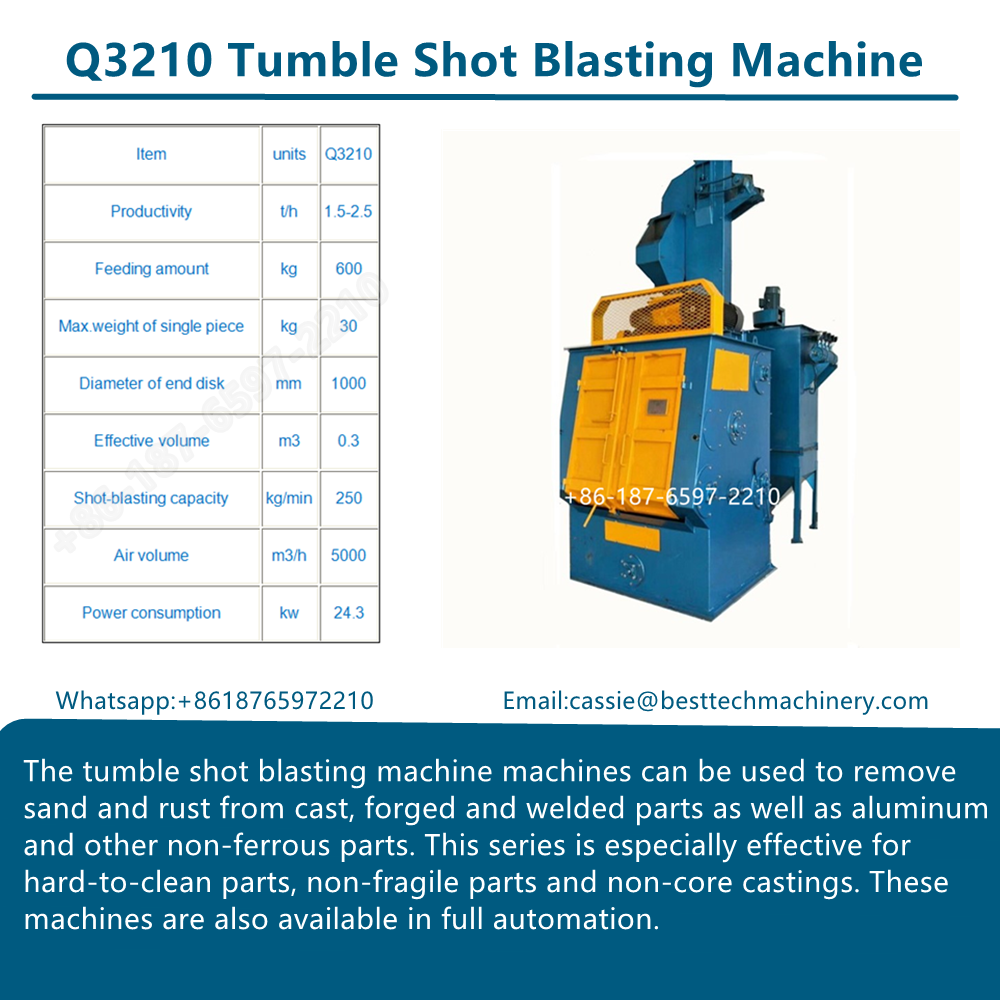

- Q3210

These models differ in drum size, load capacity, blast wheel power, and production speed.

Why Choose Tumble Shot Blast Machines?

In modern manufacturing and metal processing, surface preparation is a crucial step to ensure product quality, durability, and aesthetics. Among the many types of shot blasting equipment available, tumble shot blast machines stand out for their versatility, efficiency, and cost-effectiveness—especially when dealing with high volumes of small to medium-sized parts. But why should you choose a tumble shot blast machine? Here are the key reasons:

1. Uniform and Thorough Cleaning

Tumble shot blast machines use a rotating drum or belt to gently tumble parts while blasting them with high-speed abrasive media. This tumbling action ensures that all sides of the workpieces are evenly exposed to the abrasive, resulting in consistent surface cleaning, even in hard-to-reach areas.

2. Ideal for Batch Processing

These machines are specifically designed for batch operations, making them perfect for cleaning a large number of small or irregularly shaped metal parts at once. Whether it’s nuts, bolts, gears, castings, or forgings, tumble shot blasters can handle them efficiently and uniformly.

3. High Efficiency with Low Labor Costs

Tumble shot blast machines are often equipped with automatic loading, unloading, and abrasive recycling systems. This automation significantly reduces manual labor, speeds up the production cycle, and minimizes downtime—making them ideal for high-volume industrial environments.

4. Compact and Enclosed Design

These machines typically feature a compact footprint, which saves valuable floor space. The fully enclosed blasting chamber also reduces dust and noise, helping to maintain a clean and safe working environment.

5. Cost-Effective Operation

Tumble blasters are designed to recycle abrasives and operate with low energy consumption, which lowers operating costs over time. Their durable construction and low maintenance requirements also contribute to long-term savings.

6. Versatile Applications

Tumble shot blast machines are widely used across different industries:

- Foundries: For cleaning sand and scale from castings.

- Forging Plants: For descaling forged components.

- Heat Treatment Workshops: For cleaning oxidized and heat-treated parts.

- Automotive and Aerospace: For cleaning precision parts before coating or assembly.

- General Metal Fabrication: For rust, scale, and paint removal.

7. Gentle on Delicate Parts

With rubber or polyurethane belt options, tumble shot blasters can handle delicate or softer components without damage—while still delivering excellent cleaning results.

Choosing a tumble shot blast machine means investing in a proven, efficient, and flexible surface treatment solution. Whether you’re dealing with heavy-duty castings or precision-engineered parts, these machines provide a cost-effective way to improve product quality, reduce labor, and increase overall productivity. If batch cleaning and uniform results are your priority, tumble shot blasting is the smart choice.

Conclusion

Tumble shot blast machines are an efficient and reliable solution for batch cleaning of small and medium-sized metal parts. Their compact design, uniform cleaning performance, and automation capabilities make them an ideal choice for industrial surface treatment operations. Whether for descaling, deburring, or rust removal, these machines help manufacturers achieve high-quality finishes with reduced labor and improved productivity.