Still Struggling with Metal Surface Treatment Efficiency? Try Tumble Shot Blaster – An Efficient Solution for Metal Surface Preparation

In today’s competitive manufacturing environment, efficient metal surface preparation is essential to ensure high-quality finishes, improve adhesion for coatings, and extend the lifespan of components. However, many industries still face challenges in optimizing this process, from inconsistent cleaning results to time-consuming manual operations. If you’re still struggling with surface treatment efficiency, it might be time to consider the tumble shot blaster—a highly effective and automated solution for metal surface preparation.

What is a Tumble Shot Blaster?

A tumble shot blaster is a type of shot blasting machine that uses a rotating rubber or steel belt to tumble metal parts while blasting them with high-speed abrasive media. This combination of tumbling and blasting ensures that all surfaces of the parts, even those with complex shapes, are thoroughly cleaned or treated.

How Does It Improve Surface Treatment Efficiency?

- Automated Cleaning Process

Unlike manual cleaning methods, tumble shot blasters automate the surface treatment process, reducing labor costs and operator fatigue while improving consistency. - 360-Degree Coverage

The continuous tumbling motion exposes all sides of the workpieces, ensuring uniform surface treatment even on irregular or intricate shapes. - High Throughput

Ideal for batch processing, tumble shot blasters can handle multiple parts at once, significantly increasing productivity and minimizing downtime. - Cost Efficiency

With reduced labor requirements, faster cycle times, and longer-lasting parts, tumble shot blasting lowers overall operational costs over time. - Versatility in Applications

Tumble shot blasters are suitable for cleaning, descaling, deburring, and surface roughening of a wide range of materials, including castings, forgings, and heat-treated parts.

Why Choose a Tumble Shot Blaster?

If your current surface treatment process is slowing down production or failing to meet quality standards, the tumble shot blaster offers a smart upgrade. It streamlines metal cleaning operations, enhances quality control, and provides a reliable, repeatable process for industrial-scale production.

Final Thoughts

Don’t let outdated surface treatment methods hold your operation back. By integrating a tumble shot blaster, manufacturers can achieve better finishes, faster processing times, and reduced costs. Whether you’re cleaning small castings or preparing metal parts for coating, this powerful machine can be the key to transforming your surface treatment efficiency.

Tumble Shot Blaster Introduction

The Tumble Shot Blaster represents a significant advancement in automated surface finishing technology. Designed for high-volume processing of small to medium-sized parts, this versatile machine utilizes controlled abrasive blasting within a rotating tumbler barrel to efficiently clean, descale, deburr, polish, and enhance the surface profile of components. Ideal for manufacturers across diverse sectors like automotive, aerospace, foundry, and machining, the Tumble Shot Blaster delivers consistent results with minimal operator intervention.

Core Function & Working Principle

At its heart, the Tumble Shot Blaster operates on a straightforward yet highly effective principle:

- Loading: Components are placed into a perforated, rotating barrel or drum within the blast chamber.

- Tumbling & Blasting: As the barrel rotates, the parts cascade and tumble freely. Simultaneously, a high-velocity stream of abrasive media (such as steel shot, grit, ceramic beads, or glass beads) is propelled directly into the tumbling mass using a centrifugal wheel blast system.

- Impact & Action: The combined action of mechanical tumbling and the kinetic energy of the abrasives impacts all surfaces of the parts – even complex geometries and internal features. This effectively removes contaminants (rust, scale, paint, oxides), breaks sharp edges (deburring), smooths surfaces, induces compressive stresses (shot peening), or prepares surfaces for coating.

- Separation & Recirculation: Spent abrasive and removed debris fall through the perforations in the barrel. An integrated separation system (typically involving an air wash separator) cleans the abrasive media, removing fines and contaminants, and recirculates the reusable abrasive back to the blast wheel reservoir. Waste material is collected in a hopper.

- Unloading: Once the cycle is complete, the barrel rotation stops, and the processed parts are unloaded, ready for the next stage of production or assembly.

Key Advantages of Tumble Shot Blasting

- Uniform Finishing: Ensures consistent processing of all surfaces, even intricate parts and blind holes, due to the constant tumbling action and multi-directional abrasive impact.

- High Throughput: Capable of processing large batches of parts simultaneously, significantly increasing productivity compared to manual or single-piece blasting methods.

- Reduced Labor Costs: Highly automated operation minimizes the need for manual handling and supervision throughout the blasting cycle.

- Versatility: Adaptable to a wide range of part sizes (within the barrel capacity) and materials (metals, alloys, some plastics). Easily tailored by changing abrasive type, size, blast pressure, and cycle time.

- Efficient Abrasive Use: Closed-loop recirculation and separation systems maximize abrasive life and minimize consumption.

- Dust Control: Integrated dust collection systems effectively capture airborne particles, maintaining a cleaner work environment and meeting environmental regulations.

- Improved Surface Properties: Can enhance fatigue life (via shot peening), improve adhesion for coatings, and create desired surface textures.

- Gentler Handling: Often gentler on delicate parts than vibratory finishing, reducing the risk of part-on-part damage.

Typical Applications

Tumble Shot Blasters are exceptionally well-suited for processing:

- Castings (removing sand, scale, flashing)

- Forgings (descale, deburr)

- Machined parts (remove burrs, tool marks, prepare for plating/painting)

- Stamped parts (deburr, descale, clean)

- Small weldments (remove spatter, scale)

- Fasteners (bolts, nuts, screws – cleaning and peening)

- Valve bodies and fittings

- Gears and sprockets

- Medical implants and instruments (using specific biocompatible media)

- Jewelry components

How to Choose the Right Tumble Shot Blaster

When it comes to industrial surface preparation, the tumble shot blaster is a powerful and efficient solution. Whether you’re cleaning castings, removing rust, or preparing metal surfaces for coating, choosing the right tumble shot blaster is crucial for achieving optimal results. But with various models and configurations available, how do you select the best one for your application?

This guide highlights the key factors to consider when choosing the right tumble shot blaster for your operation.

1. Workpiece Size and Weight

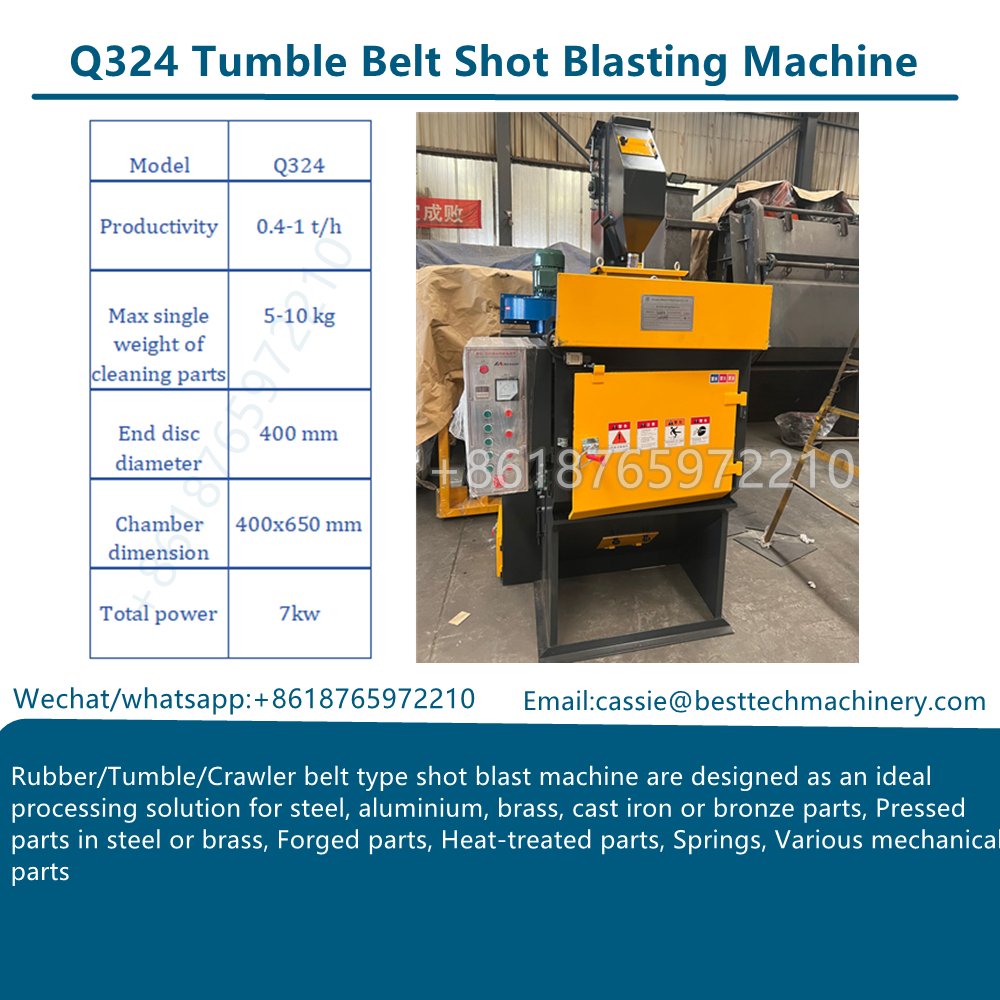

Start by evaluating the dimensions and weight of the parts you need to clean. Tumble shot blasters are designed for small to medium-sized components that can roll or tumble. Ensure the machine’s load capacity, chamber size, and belt construction match your product range.

- For small, lightweight parts: Consider a compact model like Q326.

- For heavier or larger batches: Look for machines with reinforced belts and higher load capacity.

2. Production Volume and Cycle Time

How many parts do you process per shift? The right machine should handle your required throughput without causing bottlenecks.

- Batch processing: Ideal for medium to high-volume production.

- Cycle time: Choose a machine that completes the blasting process quickly while maintaining consistent quality.

3. Material Type and Surface Condition

Different materials and surface conditions may require different abrasives or machine specifications.

- Cast iron or steel: Standard steel shot is often used.

- Aluminum or softer metals: A gentler abrasive and lower blasting power may be needed to avoid surface damage.

- Consider whether you need to remove rust, scale, sand, or prepare the surface for coating.

4. Belt Type: Rubber vs. Steel

Tumble blasters typically use either rubber or steel belts:

- Rubber Belt: Quieter, ideal for delicate or light parts, and reduces part damage.

- Steel Belt: Durable and better for heavy, abrasive, or sharp-edged components.

Choose the belt type based on your product characteristics and wear resistance requirements.

5. Dust Collection and Abrasive Recycling System

A good tumble shot blaster should include an efficient dust collector and abrasive recycling system:

- Dust Collector: Keeps the work environment clean and improves visibility and air quality.

- Recycling System: Filters and reuses abrasive media, reducing waste and cost.

Ensure these systems are sufficient for your material and abrasive type.

6. Automation and Control Features

Modern tumble shot blasters often come with programmable logic controllers (PLC), touch screens, and automation options.

- Look for user-friendly interfaces.

- Consider machines with preset programs for consistent operation.

- Safety interlocks and maintenance alerts are also important for long-term reliability.

7. Maintenance and Spare Parts Availability

Choose a machine from a reputable manufacturer with local support and readily available spare parts. Regular maintenance ensures continuous performance, and easy access to parts minimizes downtime.

Selecting the right tumble shot blaster is about more than just the initial investment—it’s about finding a machine that fits your production needs, workpiece characteristics, and long-term goals. By carefully considering size, material, throughput, and features, you can invest in a solution that boosts efficiency, enhances quality, and reduces operating costs.

Conclusion

The Tumble Shot Blaster stands as a cornerstone technology for modern manufacturing facilities demanding efficient, high-quality, and automated surface finishing. Its ability to handle complex parts uniformly at high volumes makes it an indispensable tool for achieving superior surface integrity, enhancing product performance, and streamlining production processes. By integrating robust blasting power with controlled tumbling action, it delivers reliable results batch after batch, solidifying its role as a key asset in competitive industrial operations.