Tumble Shot Blaster Introduction

A tumble shot blaster is a specialized industrial machine designed for surface treatment of metal components. It plays a crucial role in foundries, forging plants, and metalworking industries by providing efficient cleaning and polishing solutions for various workpieces.

Definition and Basic Concept

The tumble shot blaster is a type of shot blasting equipment that utilizes a rubber or steel belt conveyor system. It is specifically engineered to process small to medium-sized metal parts through continuous tumbling action while being exposed to high-velocity abrasive media. This unique design ensures uniform surface treatment on all sides of the components.

Key Applications

- Foundry Operations:

- Removal of sand, scale, and oxides from castings

- Preparation of surfaces for painting or coating

- Deburring and edge rounding of metal parts

- Forging Industry:

- Cleaning heat-treated forgings

- Surface preparation for further machining

- General Metalworking:

- Automotive component finishing

- Machinery part surface enhancement

- Construction material treatment

Working Principle

The tumble shot blaster operates through an integrated system:

- Loading System: Parts are automatically fed into the machine

- Tumbling Mechanism: Components rotate continuously on a rubber/steel belt

- Blasting Process: High-speed steel shots or grit are propelled onto surfaces

- Separation System: Used abrasives are separated and recycled

- Unloading: Finished parts exit the machine ready for next processes

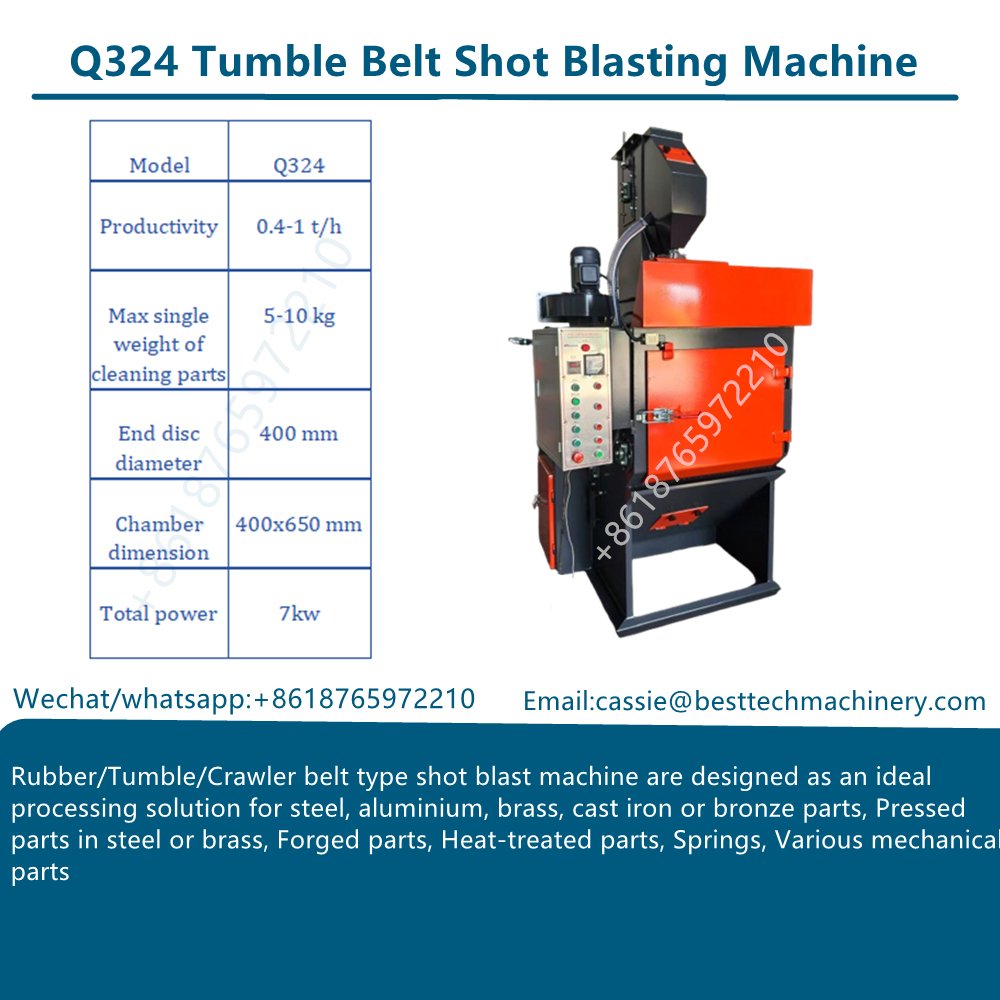

Technical Features

- Automated Operation: Minimal manual intervention required

- High Efficiency: Capable of processing large batches continuously

- Versatile Configuration: Available in various sizes and power options

- Environmental Control: Equipped with dust collection systems

Industry Significance and Trends

Tumble shot blasters have become indispensable in modern manufacturing due to:

- Increasing demand for precision surface finishing

- Growing automation in metal processing

- Stricter quality standards in automotive and aerospace sectors

Current development trends include:

- Integration with Industry 4.0 technologies

- Energy-efficient designs

- Improved abrasive recycling systems

- Enhanced safety features

How to Choose the Right Tumble Shot Blaster: A Complete Guide

Selecting the appropriate tumble shot blaster is crucial for achieving optimal surface treatment results in metalworking industries. This guide covers key considerations, model comparisons, application-specific recommendations, and purchasing evaluation points to help you make an informed decision.

1. Key Selection Factors

When choosing a tumble shot blaster, consider the following critical aspects:

a. Equipment Type

- Rubber Belt vs. Steel Belt: Rubber belts are gentler for delicate parts, while steel belts offer durability for heavy-duty applications.

- Conveyor System: Crawler-type systems (e.g., Q326) provide continuous tumbling for uniform blasting516.

b. Automation Level

- Fully automated models reduce manual intervention and improve efficiency. Look for features like automatic loading/unloading and abrasive recycling.

c. Processing Capacity

- Match the machine’s throughput (e.g., small to medium parts) with your production volume. Models like Q3210 handle larger batches.

d. Abrasive Media

- Steel shots or grit are common. Ensure compatibility with your workpiece material (e.g., castings, forgings).

e. Certifications

- CE-approved machines meet safety and environmental standards.

2. Model Comparison

| Model | Key Features | Best For |

|---|---|---|

| Q326 | Rubber belt, automatic loading | Small castings, hardware parts |

| Q3210 | Steel belt, high throughput | Medium-sized forgings |

| 15GN Series | Track-type design, heavy-duty | Large-scale foundries |

3. Application-Specific Recommendations

a. Foundries

- Priority: Sand/scale removal from castings.

- Recommended Models: Q32 series with high cleanliness standards.

b. Forging Plants

- Priority: Heat-treated forging cleaning.

- Recommended Models: Heavy-duty crawler-type blasters (e.g., 15GN Series).

c. General Metalworking

- Priority: Versatility for diverse parts.

- Recommended Models: Q326 for its balance of automation and flexibility.

4. Purchasing Evaluation

a. After-Sales Support

- Opt for suppliers offering lifetime service or at least 1-year warranties.

b. Maintenance Costs

- Factor in abrasive consumption and dust collection system upkeep. Automated models may reduce long-term costs.

c. Customization

- Ensure the machine can be tailored to your workpiece size and production line.

d. Supplier Reputation

- Verify export experience and customer reviews。

Choosing the right tumble shot blaster requires balancing technical specifications, application needs, and budget. Prioritize certified, automated models with robust after-sales support to maximize ROI. For specialized applications, consult suppliers for tailored solutions.

Conclusion

As a vital surface treatment solution, the tumble shot blaster continues to evolve to meet industrial demands. Its combination of efficiency, versatility, and reliability makes it a preferred choice for metal component processing across various sectors. Future advancements will likely focus on smarter controls and more sustainable operation methods.