In the demanding world of metalworking, foundry operations, and industrial component manufacturing, achieving consistent, high-quality surface preparation is paramount. Enter the Tumble Shot Blasting Machine – a workhorse of mass finishing renowned for its efficiency, versatility, and ability to deliver uniform results on large volumes of small-to-medium sized parts.

Shot blasting machines are the unsung heroes of modern industry, quietly ensuring the quality, durability, and safety of countless metal products.

What is a Tumble Shot Blasting Machine?

A tumble shot blasting machine is an industrial workhorse designed for high-volume, automated surface treatment of small-to-medium-sized metal parts. It efficiently cleans, descales, deburrs, peens, or finishes components by bombarding them with abrasive media while they rotate in a drum. Think of it as an industrial “washing machine” that uses abrasive particles instead of water to aggressively refine surfaces.

How It Works: The Tumbling Action

The core principle is elegantly simple yet highly effective:

- Loading: Parts are loaded into a large, robust, rotating drum or barrel.

- Rotation: The drum rotates continuously at a controlled speed.

- Blasting: High-velocity abrasive media (steel shot, cut wire, aluminum oxide grit, etc.) is propelled onto the tumbling parts by one or more powerful blast wheels mounted inside the drum.

- Tumbling Action: As the drum rotates, parts cascade and tumble over each other. This continuous movement exposes every surface – intricate geometries, recesses, cavities, and threads – to the abrasive stream, ensuring comprehensive coverage and uniform treatment.

- Separation & Recycling: Spent abrasive, dust, and removed surface contaminants fall through perforations or a grate in the drum floor into a lower chamber. Here, a separator system (typically an air wash separator or vibratory screen) cleans the reusable abrasive, removing fines and debris, and recirculates it back to the blast wheel(s). Contaminants are collected by a dust collector for disposal.

- Unloading: After the preset cycle time completes, the drum stops at an unloading position, and the finished parts are discharged, often via a chute or conveyor.

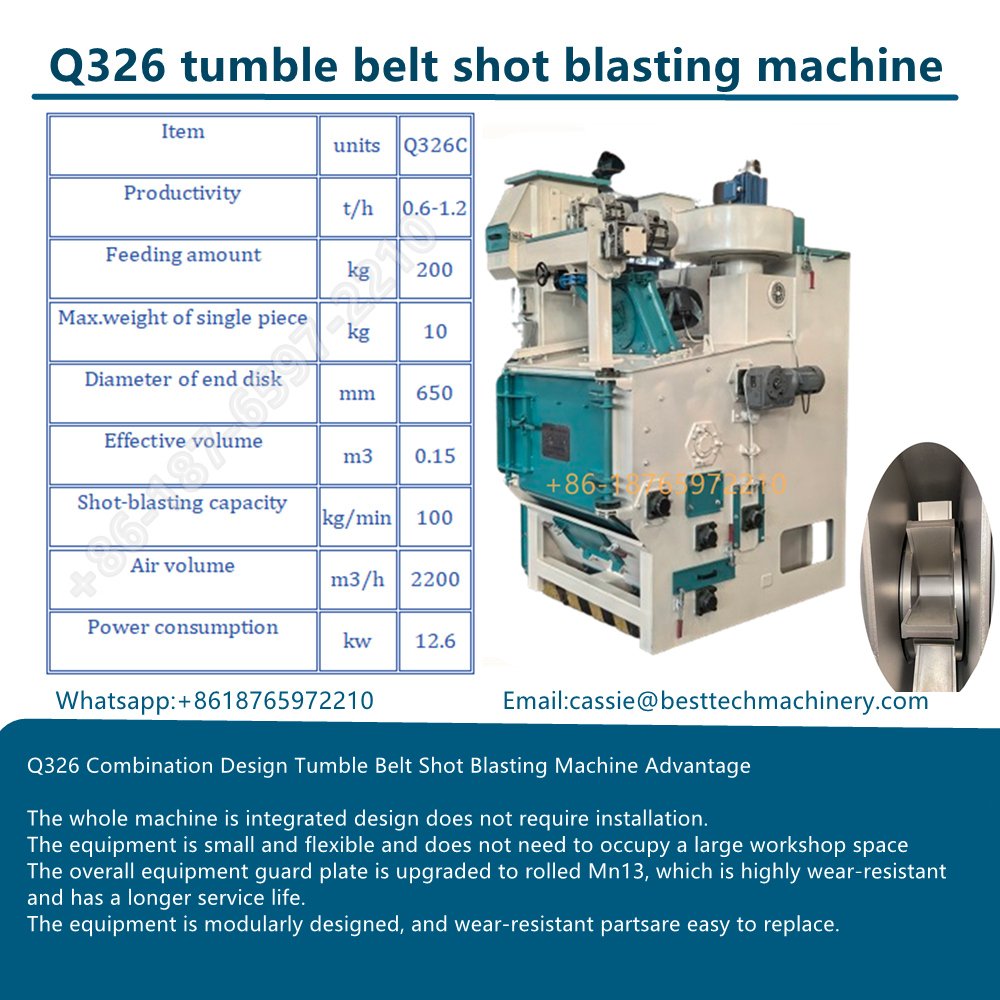

Key Components:

- Rotating Drum/Barrel: The main chamber where tumbling and blasting occur, designed for durability and wear resistance.

- Blast Wheel(s): The heart of the system, utilizing centrifugal force to accelerate abrasive media to high speeds.

- Abrasive Handling System: Includes storage hopper, feed control valve, blast wheel(s), separator, and recycle elevators/conveyors.

- Dust Collector: Essential for capturing fine particulate matter (dust, spent abrasive fines, removed scale/rust) to maintain air quality and meet environmental regulations.

- Drive System: Electric motor and gearbox to rotate the drum.

- Control Panel: For setting rotation speed, cycle time, blast intensity monitoring, and safety interlocks.

Why Choose a Tumble Shot Blaster? Key Advantages:

- Uniformity & Consistency: The tumbling action ensures all surfaces of every part experience similar blast intensity, leading to highly consistent results batch after batch.

- High Throughput: Capable of processing large volumes of parts simultaneously, significantly boosting productivity compared to manual or single-piece methods.

- Excellent Coverage: Ideal for parts with complex shapes, holes, threads, or internal passages where manual blasting or static machines struggle.

- Automation & Labor Savings: Once loaded and started, the process runs automatically until completion, minimizing operator involvement.

- Versatility: Handles a wide range of part sizes (typically suited for small to medium parts, though capacities vary) and materials (castings, forgings, stampings, weldments). Achieves various surface finishes (cleaning, descaling, deburring, peening, matte finishing) by changing abrasive type and size.

- Closed Loop System: Highly efficient abrasive recycling minimizes media consumption and waste generation.

- Dust Control: Integrated dust collection systems maintain a cleaner work environment.

Common Applications:

- Descaling: Removing mill scale, heat treat scale, and rust from steel forgings, castings, and fabrications.

- Deburring: Removing sharp edges, parting lines, and flash after machining, casting, or stamping.

- Surface Cleaning: Preparing surfaces for painting, coating, plating, or bonding by removing oil, grease, dirt, and old coatings.

- Surface Finishing: Achieving specific surface textures (e.g., matte, satin finish).

- Shot Peening: Inducing beneficial compressive stresses to improve fatigue life (requires specific media and control).

- Industries Served: Automotive, aerospace, foundry, forging, agriculture, construction, general metal fabrication, fastener manufacturing.

Important Considerations:

- Part Size & Fragility: Best suited for parts that are robust enough to withstand tumbling without damage. Very large, heavy, or extremely delicate parts may be unsuitable.

- Cycle Time: Achieving the desired finish level requires optimizing cycle time, drum speed, abrasive type/size, and blast pressure.

- Media Selection: Critical for achieving the desired result (cleaning vs. peening vs. finishing).

- Maintenance: Regular wear part inspection and replacement (liners, blades, elevator buckets) are essential for sustained performance.

- Footprint & Investment: Requires significant floor space and represents a substantial capital investment.

Tumble Blasting vs. Vibratory Finishing: While both handle bulk parts, tumble blasting delivers much more aggressive surface modification (descaling, heavy deburring) due to the high-energy impact of the propelled abrasive. Vibratory finishing uses gentler sliding/rolling action with abrasive media for lighter deburring, edge rounding, and polishing.

Hidden Crisis in Modern Manufacturing Without Shot Blasting

In the highly competitive landscape of modern manufacturing, surface preparation is often overlooked, yet it plays a critical role in ensuring product durability, quality, and performance. Shot blasting, a vital surface treatment process, is integral to achieving these outcomes. However, many manufacturers continue to operate without this technology, unaware of the hidden crisis it may be causing in their production systems.

The Importance of Shot Blasting

Shot blasting is a mechanical process that uses a stream of abrasive material propelled at high velocity to clean, strengthen, or polish metal surfaces. It is widely used for:

- Removing rust, scale, and old coatings

- Improving surface adhesion before painting or coating

- Enhancing fatigue resistance through surface hardening

- Cleaning castings, forgings, and welded components

By creating a clean, roughened surface, shot blasting ensures that coatings adhere better and last longer, and that metal parts can perform under extreme mechanical stress.

What Happens Without Shot Blasting?

Without shot blasting, manufacturing processes are more vulnerable to a range of quality, performance, and safety issues:

1. Poor Surface Preparation

Inadequate cleaning of surfaces before painting or coating leads to weak adhesion. Over time, this causes coatings to peel, corrode, or crack—resulting in expensive rework, warranty claims, or even product failure.

2. Increased Corrosion Risk

Rust, scale, and surface contaminants left on untreated parts can accelerate corrosion. For industries like automotive, aerospace, and construction, corrosion is a critical threat to safety and longevity.

3. Reduced Fatigue Life

Shot blasting helps create compressive stress layers on metal surfaces, enhancing their fatigue resistance. Without this treatment, components are more susceptible to stress cracks and early failure.

4. Inconsistent Product Quality

Lack of uniform surface preparation leads to inconsistent finishes, dimensional inaccuracies, and lower-quality products. This not only affects brand reputation but also customer satisfaction.

5. Non-Compliance with Industry Standards

Many industries have strict standards for surface cleanliness and preparation. Without shot blasting, companies risk falling short of these requirements, leading to potential rejections and loss of contracts.

The Long-Term Cost of Neglect

While skipping shot blasting may seem like a cost-saving measure initially, it often results in higher long-term expenses due to:

- Increased maintenance and repairs

- Product recalls or returns

- Shorter equipment lifespan

- Higher customer dissatisfaction

More importantly, it could lead to missed business opportunities where surface integrity and finishing are critical requirements.

A Silent Risk No Manufacturer Can Ignore

The absence of shot blasting in modern manufacturing represents a silent but significant risk. From compromised product performance to escalating operational costs, the consequences are far-reaching. Manufacturers must recognize shot blasting not as an optional process, but as a foundational pillar of quality assurance and surface engineering. Investing in reliable shot blasting equipment today is essential to staying competitive, compliant, and sustainable in tomorrow’s industrial world.

Conclusion:

The tumble shot blasting machine remains a cornerstone technology for efficient, high-volume surface preparation and finishing of small-to-medium metal components. Its ability to deliver uniform results, handle complex geometries, and operate with high productivity makes it indispensable in countless manufacturing sectors. By automating a critical process while ensuring quality and consistency, the tumble blaster significantly contributes to streamlined production lines and superior finished products. When robustness, uniformity, and throughput are paramount, the tumble shot blaster is often the optimal solution.