In the world of industrial manufacturing and metalworking, achieving a flawless surface finish or thorough cleaning of components is paramount.

Tumbler blaster—a versatile, efficient machine designed to automate and enhance processes like deburring, descaling, polishing, and surface preparation through abrasive blasting.

This article explores how tumbler blasters work, their applications, and why they’re indispensable in modern workflows.

What Is a Tumbler Blaster?

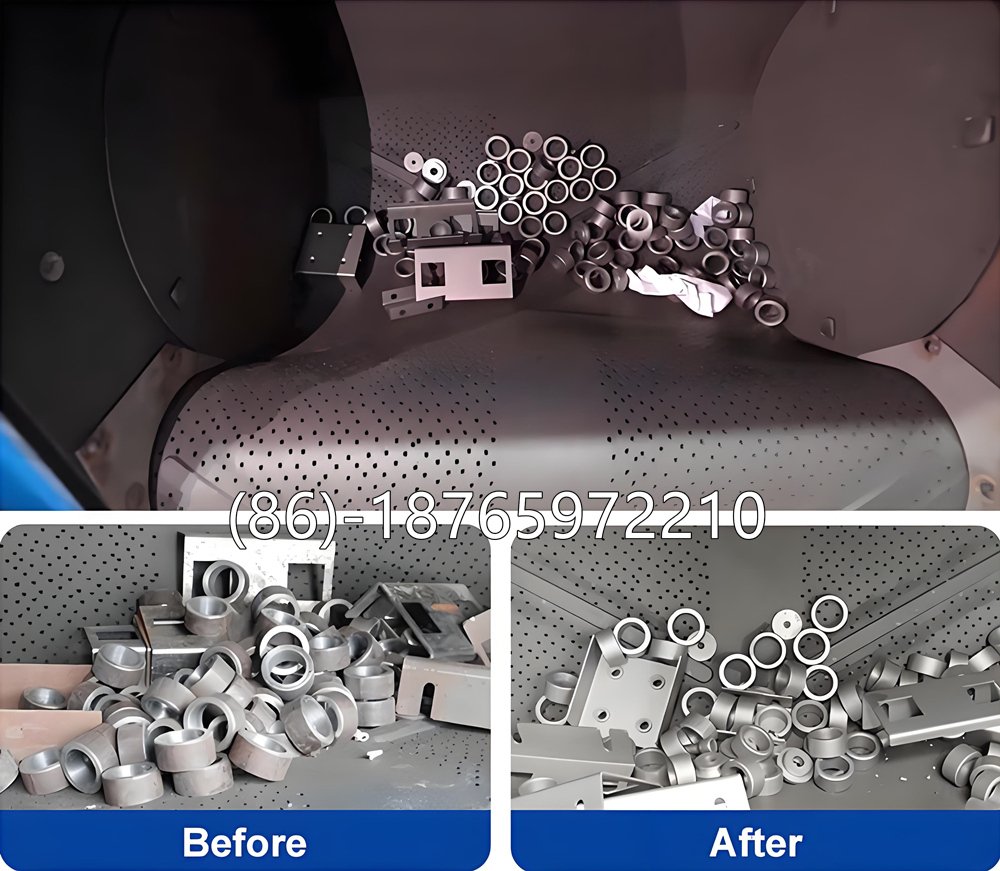

A tumbler blaster, also known as a tumble shot blasting machine, is a type of surface treatment equipment that uses abrasive media propelled by a high-speed blast wheel to clean or finish parts. The parts are loaded into a rotating drum or rubber belt where they tumble continuously, allowing all surfaces to be uniformly treated.

This fully automated process is especially effective for small to medium-sized parts that can withstand impact and require thorough and consistent surface treatment.

How Tumbler Blasters Work

A tumbler blaster combines tumbling (barrel rotation) with abrasive blasting (high-pressure propulsion of media). Components are loaded into a rotating drum or barrel. As the drum turns, abrasive media (such as steel shot, ceramic grit, or walnut shells) is propelled at high velocity onto the parts. This dual-action mechanism ensures:

- Uniform Coverage: Rotation exposes all surfaces to the abrasive stream.

- Gentle Handling: Tumbling prevents part-on-part damage.

- Efficiency: Blasting accelerates material removal compared to tumbling alone.

Key Applications

Tumbler blasters excel in industries requiring precision surface treatment:

- Automotive: Cleaning engine blocks, deburring gears, polishing valves.

- Aerospace: Removing oxidation from turbine blades, preparing components for coating.

- Foundries: Descaling castings, eliminating sand residue.

- Medical: Polishing surgical instruments without compromising precision.

- Jewelry: Restoring metal pieces and removing tarnish.

Advantages Over Traditional Methods

- Speed: Processes large batches in minutes vs. hours with manual blasting.

- Consistency: Eliminates human error, ensuring uniform results.

- Labor Savings: Fully automated operation reduces staffing needs.

- Versatility: Adjustable rotation speed, blasting pressure, and media type cater to diverse materials (metal, plastic, ceramic).

- Dust Control: Closed-loop systems with integrated filters contain airborne particles, enhancing workplace safety.

Types of Tumbler Blasters

- Rotary Barrel Tumblers: Ideal for heavy, durable parts; robust construction for high-impact tasks.

- Vibratory Tumblers: Best for delicate parts; uses vibration instead of rotation for gentler action.

- Continuous Systems: Automate loading/unloading for high-volume production lines.

Choosing the Right Media

Media selection depends on the desired outcome:

- Aggressive Cleaning: Steel grit or aluminum oxide.

- Fine Finishing: Glass beads or ceramic spheres.

- Eco-Friendly: Crushed walnut shells or corn cob grit for softer materials.

Safety and Sustainability

Modern tumbler blasters prioritize:

- Operator Safety: Sealed chambers, automated controls, and HEPA filtration.

- Media Recycling: Built-in reclaim systems reduce waste and costs.

- Noise Reduction: Sound-dampening enclosures for compliance with workplace regulations.

The Future of Tumbler Blasting

Advances in automation (IoT sensors, AI-driven process optimization) and eco-friendly media are making tumbler blasters smarter and greener. Integration with Industry 4.0 allows real-time monitoring of parameters like media degradation and part coverage, boosting quality control.

Why Tumbler Blasters Are Indispensable in Modern Workflows?

In today’s fast-paced and quality-driven manufacturing environment, efficiency, precision, and consistency are non-negotiable. As industries seek to optimize operations and reduce costs without compromising product quality, tumbler blasters have become an indispensable part of modern production workflows.

1. Automation Enhances Productivity

Modern manufacturing demands speed. Tumbler blasters automate the surface finishing process by allowing batch treatment of small to medium-sized parts. Operators simply load the parts, start the machine, and the system takes care of the rest—cleaning, deburring, and finishing in one continuous cycle. This eliminates manual labor, speeds up processing, and reduces human error.

2. Uniform Surface Treatment

Unlike manual blasting or static systems that may leave blind spots, the tumbling motion ensures that every part surface is exposed evenly to the abrasive media. This uniformity is essential for preparing parts for coating, welding, or assembly, as it ensures consistent adhesion and long-term durability.

3. Cost-Effective and Scalable

Tumbler blasters allow mass processing of components, lowering the cost per part. They are ideal for manufacturers who need to treat thousands of parts daily without excessive investment in labor or time. The scalability of the system makes it suitable for both small workshops and large industrial plants.

4. Versatility Across Industries

Whether it’s removing rust from castings, descaling forged parts, or preparing surfaces for painting or coating, tumbler blasters adapt to a wide range of applications. They are widely used in sectors like automotive, aerospace, foundry, machining, and hardware manufacturing.

5. Consistency Supports Quality Control

In industries where consistency defines quality, tumbler blasters deliver reliable and repeatable results. Every batch undergoes the same treatment cycle, reducing variability and ensuring compliance with industry standards and customer expectations.

6. Compact Footprint, High Output

Tumbler blasters are designed to be space-efficient, making them suitable even for facilities with limited floor area. Despite their compact design, they offer high throughput, helping businesses maximize production in smaller footprints.

7. Low Maintenance, High Durability

Built from wear-resistant materials and engineered for durability, tumbler blasters require minimal maintenance. This reduces machine downtime and ensures continuous operation, which is crucial for meeting tight production schedules.

As manufacturing evolves, the demand for faster, cleaner, and more consistent surface treatment continues to rise. Tumbler blasters meet these needs with unmatched efficiency, making them a core component in modern industrial workflows. Their ability to automate, standardize, and scale surface finishing processes makes them not just useful—but truly indispensable.

How Tumbler Blasters Are Revolutionizing the Industry?

In an era defined by automation, efficiency, and quality, manufacturers are constantly seeking technologies that deliver better results at lower costs. One such technology making a significant impact across various sectors is the tumbler blaster. From foundries to automotive workshops, these machines are changing how surface treatment and cleaning are performed—ushering in a new standard for productivity and precision.

1. Automated Surface Treatment for Mass Production

Tumbler blasters automate the traditionally labor-intensive task of surface cleaning. By allowing parts to tumble continuously inside a drum or rubber belt while being blasted with high-speed abrasive media, the machines enable batch processing of multiple components. This dramatically reduces manual handling, speeds up production, and ensures uniform treatment.

2. Uniform, High-Quality Finishes

The continuous tumbling motion of parts ensures that all surfaces are equally exposed to the abrasive stream. This results in even and consistent cleaning, which is critical for applications where surface preparation affects downstream processes such as painting, coating, welding, or assembly. Tumbler blasters eliminate inconsistencies common in manual or fixed blasting methods.

3. Reduced Labor and Operational Costs

By integrating tumble blasting machines into their workflows, companies are significantly reducing labor costs. One operator can manage multiple machines, and each batch requires minimal supervision. Additionally, the durable design and low maintenance needs of tumbler blasters contribute to long-term savings on repairs and downtime.

4. Increased Throughput and Efficiency

Tumbler blasters offer high-capacity performance in a compact footprint. Whether cleaning castings, descaling forgings, or removing burrs from machined parts, they increase throughput without expanding factory space. Their continuous operation capabilities make them ideal for industries with high production demands.

5. Eco-Friendly and Dust-Controlled Systems

Modern tumbler blasters are equipped with efficient dust collection systems and noise-reduction designs, making them more environmentally friendly and workplace-safe. Many models are also designed to recycle abrasive media, further reducing waste and operating costs.

6. Versatility Across Multiple Industries

From automotive and aerospace to hardware and foundry operations, tumbler blasters are used for a variety of surface preparation tasks. Their ability to handle different materials—steel, aluminum, cast iron, and more—makes them adaptable to a wide range of industrial needs.

Tumbler blasters are not just improving how surface treatment is done—they are redefining the standards of industrial cleaning and finishing. With their blend of automation, uniformity, cost-efficiency, and environmental compliance, these machines are revolutionizing production lines across the globe. For manufacturers aiming to stay competitive, investing in tumbler blasting technology is no longer optional—it’s essential.

Conclusion

Tumbler blasters are a cornerstone of efficient industrial surface treatment, blending abrasion and motion to deliver precision at scale. From revitalizing vintage car parts to preparing aerospace components for critical coatings, they offer unparalleled speed, consistency, and versatility. As technology evolves, these machines will continue to redefine the standards of finish and cleanliness across sectors.