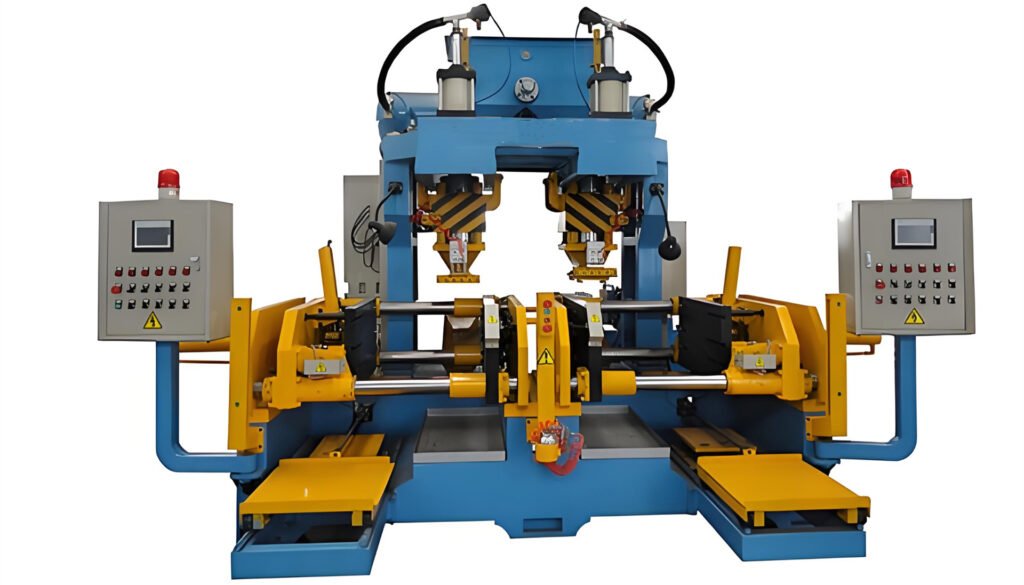

Shell core machines are essential equipment in the metal casting industry, used to create complex, high-quality sand cores for molds. These machines employ the shell molding process, a method known for its precision, repeatability, and ability to produce intricate geometries with excellent surface finishes.

What Is Shell Core Machine?

A shell core machine is designed to produce sand cores by using a heated metal pattern and resin-coated sand. When the heated pattern comes into contact with the sand, the outer layer cures and forms a hard “shell” while the remaining uncured sand is removed, leaving a hollow, lightweight core. This process enables the efficient production of cores with precise dimensional control.

Key Components and Working Principle

The core components of a shell core machine typically include:

- Heated core box (pattern tool)

- Sand hopper and blow system

- Core ejection mechanism

- Temperature control system

- Dust collection system

Working Process:

- Sand Blowing: Resin-coated sand is blown into the heated core box.

- Curing: Heat from the core box initiates the curing process, hardening the outer shell of the core.

- Sand Dumping: Uncured sand is removed from the center, creating a hollow core.

- Cooling and Ejection: The core is cooled and then ejected from the machine for use in mold assemblies.

Advantages of Shell Core Machines

- High dimensional accuracy: Suitable for complex geometries and thin-walled cores.

- Excellent surface finish: Reduces the need for machining after casting.

- Fast cycle time: Ideal for medium to high-volume production.

- Material savings: Uses less sand and binder due to the hollow structure.

- Automated operation: Enhances productivity and reduces labor requirements.

Applications

Shell core machines are widely used in industries such as:

- Automotive: Engine blocks, cylinder heads, and transmission components.

- Aerospace: Precision castings for turbines and structural parts.

- Industrial Machinery: Pump housings, valves, and compressors.

- Marine and Rail: Large, complex castings requiring high strength and accuracy.

Why Choose Shell Core Machine for Your Foundry?

In modern foundries, efficiency, precision, and consistency are critical. Among the various technologies available for core-making, the Shell Core Machine stands out as a top choice for manufacturers seeking high-quality results. Here’s why choosing a shell core machine is a smart investment for your casting operation.

1. High Precision and Dimensional Accuracy

Shell core machines use heated metal tooling and resin-coated sand to create cores with exceptional accuracy. This process allows for the production of intricate and complex shapes with tight tolerances, reducing the need for post-processing and improving final casting quality.

2. Excellent Surface Finish

The shell molding process provides a smooth surface finish, which enhances the quality of the final cast product. A better surface finish means fewer defects, less machining, and improved aesthetics—especially important in industries like automotive and aerospace.

3. Fast and Efficient Production

With rapid cycle times, shell core machines are ideal for high-volume production. The quick curing process and automation-friendly design allow for faster core output compared to traditional core-making methods, improving overall productivity.

4. Material and Energy Efficiency

Shell core machines produce hollow cores, using less sand and binder compared to solid-core methods. This not only saves material costs but also reduces the energy required for core production and handling, making the process more sustainable.

5. Strong and Durable Cores

The heat-cured resin bonds create strong and dimensionally stable cores that can withstand high temperatures and pressures during the metal pouring process. This ensures reliability and minimizes the risk of defects in the final casting.

6. Automation and Integration

Modern shell core machines can be integrated with robotic arms, conveyors, and automated sand systems, allowing for seamless operation and reduced labor costs. Automation also improves safety and consistency across production batches.

7. Versatile Applications

From small, intricate components to large industrial parts, shell core machines are widely used across multiple sectors:

- Automotive – Engine blocks, intake manifolds

- Aerospace – Turbine blades, housings

- Industrial Equipment – Pumps, compressors, valves

- Energy Sector – Castings for wind, oil, and gas equipment

Choosing a shell core machine means investing in precision, efficiency, and long-term performance. Whether you’re upgrading your foundry operations or looking to improve casting quality and throughput, a shell core machine offers the reliability and innovation needed to stay competitive in today’s market.

Conclusion

Shell core machines have transformed modern foundry operations by enabling the rapid and accurate production of sand cores. Their ability to produce intricate, high-performance cores makes them indispensable in precision casting applications across multiple industries.