In foundry, molding machines are used to create molds for casting metal. These machines automate the process of preparing the molds for molten metal, and there are several different types, each designed for specific casting processes.

Type of molding machines in foundry

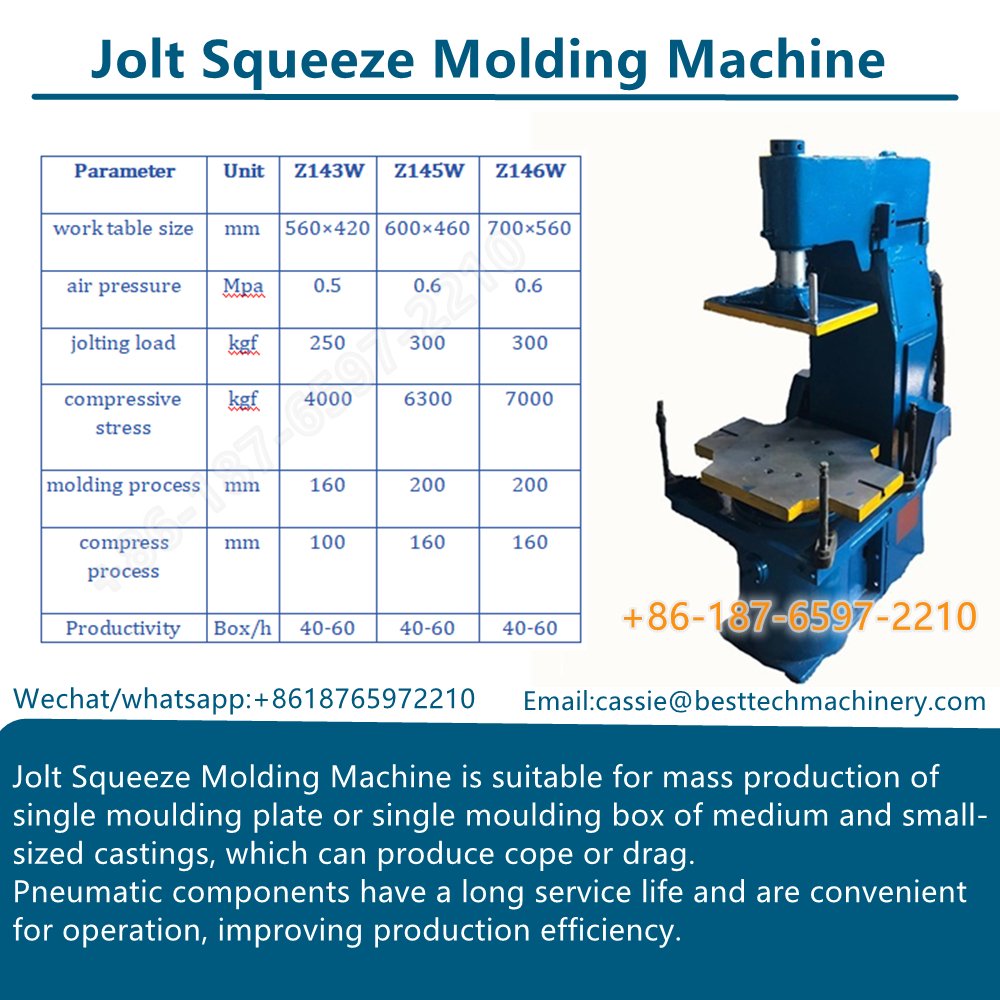

1. Jolt Squeeze Molding Machine

Jolt Squeeze Molding Machine is suitable for mass production of single moulding plate or single moulding box of medium and small-sized castings, which can produce cope or drag.

- Process: This machine works in two stages: the “jolt” stage, where the mold is compacted using mechanical vibration, and the “squeeze” stage, where the mold is compressed using a hydraulic press.

- Usage: Common for producing small to medium-sized metal castings, especially in sand casting.

2. Shell Molding Machine

Shell Molding Machines offers safe and simple operations that produce quality cores and shells.

- Process: In this process, a thin shell of sand is formed around a pattern, and the shell is hardened using heat or chemical processes. It is often used for precision casting.

- Usage: Often used for producing small, high-precision castings with intricate details.

3. Green Sand Molding Machine

Green sand molding machine is a type of molding machine used in the foundry industry to create molds for metal casting. The term “green sand” refers to the mixture of sand, clay, and water used to make molds. The sand is called “green” because it is not baked or hardened before molding, unlike other types of sand used in casting.

- Process: Uses green sand (a mixture of sand, clay, and water) to make molds. The machine presses sand around the pattern, and it is then removed to form the mold.

- Usage: Common for high-volume production, such as automotive components and large parts.

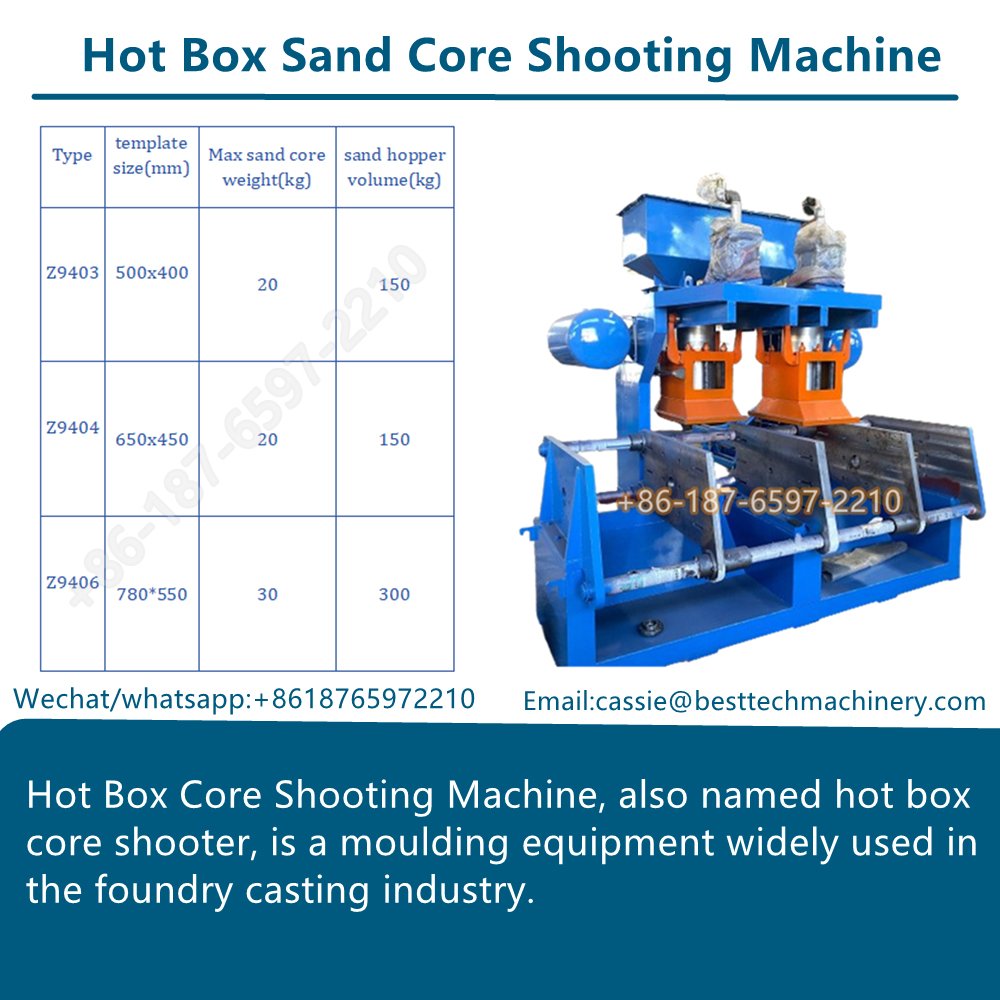

4. Core Making Machine

Core making machines are automated machines that can produce sand cores quickly, accurately, and with high precision. These machines use a variety of techniques, such as hot box, cold box, or shell core, to create sand cores of different shapes and sizes.

- Process: Used specifically for producing cores, which are the internal parts of a casting. It typically involves molding the sand around a core box to create hollow spaces in castings.

- Usage: Used in almost all casting processes, especially for parts with internal features, like engine blocks.

5. Disamatic Molding Machine

- Process: This is an automatic, vertically-parting molding machine that uses a high-speed sand molding process. It is highly automated and uses a cold box process to harden the sand.

- Usage: Primarily used in mass production, particularly in the automotive and heavy machinery sectors.

6. Horizontal Parting Molding Machine

- Process: These machines use a horizontal parting line, where the mold halves are compressed together. They are typically used for larger molds.

- Usage: Suitable for larger and medium-sized castings, such as frames or engine blocks.

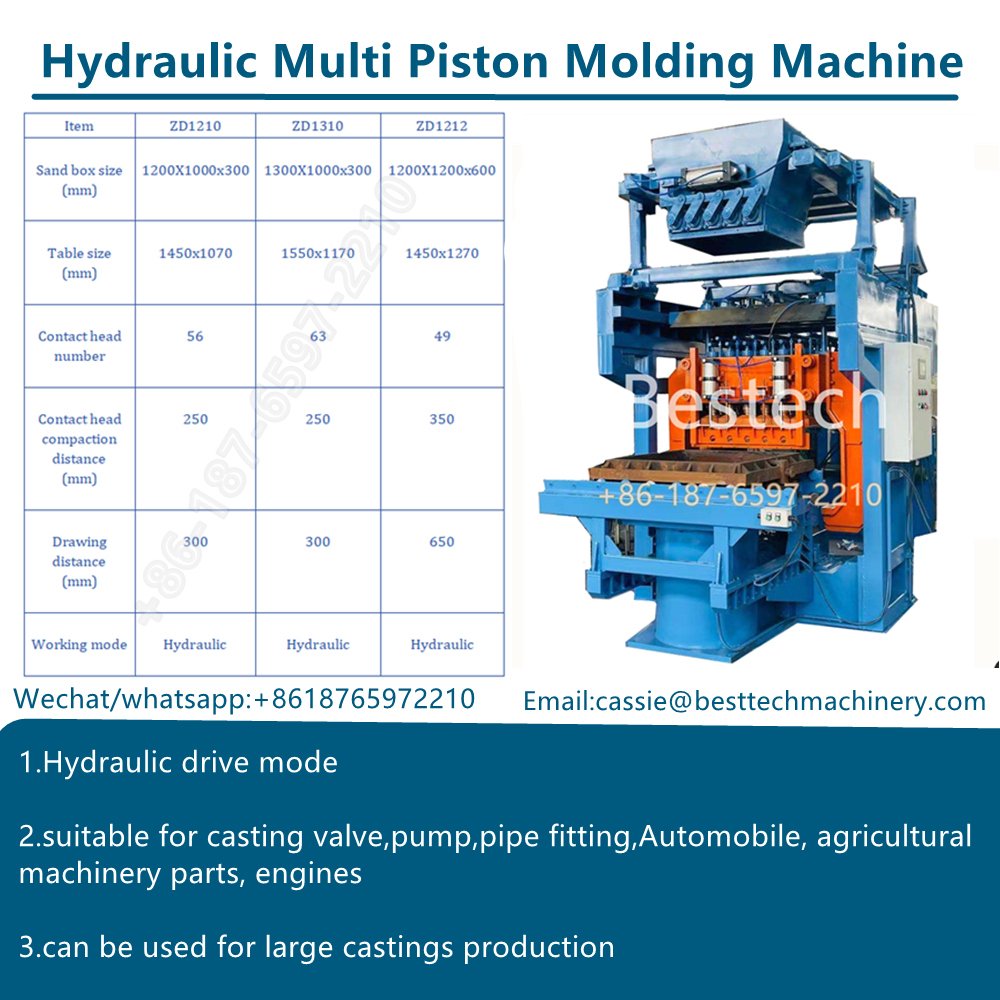

7. High Pressure Molding Machine

Multi-piston hydraulic sand molding machine (high pressure molding machine foundry)i is suitable for single side single box molding of large and medium-sized castings produced in batch, and can be used to make upper box or lower box. The single machine can realize the functions of sand mold compaction and top box mold lifting.

- Process: This involves injecting sand into a mold cavity at high pressure to form molds. The sand is compacted using high pressure, leading to highly accurate and strong molds.

- Usage: Ideal for producing complex, high-precision castings in large quantities.

8. Rotary Molding Machine

- Process: Involves a rotating mold, where molten metal is poured into the mold while it rotates. This allows for more uniform distribution of metal, and can create hollow castings.

- Usage: Primarily used for centrifugal casting and thin-walled castings.

9. Vacuum Molding Machine

- Process: Uses a vacuum to hold the sand around the pattern, and the mold is formed with reduced air pressure. This process helps reduce defects like sand inclusion and improves mold quality.

- Usage: Used for high-precision and high-quality castings, typically in the aerospace and automotive industries.

10. Furan Resin Molding Machine

- Process: These machines use furan resin (a type of chemical binder) in the molding process. The binder hardens the sand, which is then used for making molds.

- Usage: Common in high-quality sand castings where sand quality and surface finish are critical.

Conclusion

Each of these machines plays a key role in automating and improving the efficiency of the molding process in foundries. The choice of machine depends on the type of casting required, the size of the casting, the materials used, and the level of automation needed.